i cut 1/8 inch at 86.6 in/min…40 amps on a primeweld cut 60. 3/4 inch strips 14 inches long. the strips curled while cutting and remain curled after cutting. i have to cut an intricate design from 14 gauge hot rolled steel. worried about the finish. any suggestions

can you move the cuts around so you’re not continuously cutting in the same area? You may also end up having to put pauses into your code to let things cool. I’d also try to turn the amperage down or speed up the cut assuming you can do so and not sacrifice more cut quality than you can accept.

How full is your water table?

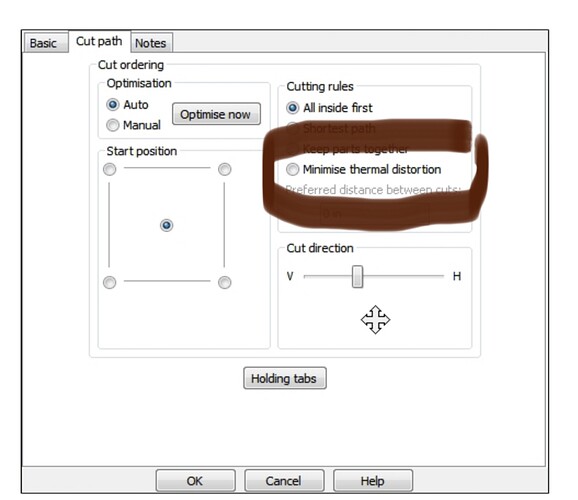

If you use sheetcam they have a setting to space out cuts to try to limit heat distortion caused by over heating one area too much.

I’m not familiar with your plasma so can’t help on that end of things but make sure you’re running a high enough speed also

I cut pretty intricate stuff out of 16G steel without much distortion usually

@Teknic where’s that setting in sheetcam? I learn something new everytime I’m in here!

You should be able to cut 1/8" at 100 IPM at 40 amps. Faster speed means less heat build up on the part and less warping.

Awesome never saw that… Thanks!

Turn up the power and turn up the speed, fill the table to the very top with water. I cut very intricate designs, but long straight lines adjacent to each other will always “pop” due to heat. But I’ve never had the actual part stay warped, just the remnants which interfere with the torch.