That is the appropriate belt tension. With the machine powered off are the ball nuts easy to turn by hand? You should be able to turn them with minimal finger pressure.

yes, they move easy both sides, both directions with no power. can just push my fingers along the belt and they rotate

Iv always been able to move the lead nut by hand when it get off track. here is my felt gap. I suppose I could remove the felt and it would be fine running them without, seems like the felt would break down overtime anyway and get stuck. I did have much better results after I fixed some issues. I’ll post more on it here. I was able to jog at 400imp for a while, dry ran a program, rehomed and then boom came right off track after homing.

Made alot of progress today, ruled out the limit switches being backwards (Cam from tech) said to trip one and you’ll see it light up on the screen, very helpful in determining that. However I don’t know how I caught this, but I noticed I had this aluminum bracket on wrong. They said it was a mirror part and I overlooked that the 90* corner need to be at bottom. So swapped it around. I went and tweaked my tubes a little bit. I was measuring the inside to outside tube like they say, but…I was measuring on the outside of the tube rather than hooking my tape on the inside of the tube, directions weren’t really clear on that part.

I was still having problems with v rollers doing a wheelie when the machine was close to home. I adjusted that again. I rehomed and was able to get the machine rapiding at 400 ipm for a while. I ran a test file for a bit etc. I homed machine again and as soon as I tried moving off home at 400 ipm it came outta wack. So I think I need to adjust the lead screws and I should be good. But I still feel like when it homes, its off one side to the other, maybe its a lead screw issue.

I did the marking shaft on motors and v belt test and it seems as if that is all good. Though they tell you to test it at 10ipm full torque, I get that theory but I think it should be tested at a faster speed as that is what causes misalignment. Case in point if machine off racks at front and you home, (120ipm) it will not bind up. So if motors are slipping how can it home?

Getting much closer. I have probably 10hrs in assembly give or take, but alot in troubleshooting, some of which is my fault. I only have a couple hours after my work to get to assemble. I think if I printed out instructions and had more time I could have avoided a few mishaps.

I was wondering if anyone on here had an issue with a noisy bearing on the y2 side. Langmuir supplied me with a new ballnut which i thought was the culprit, but it still makes a clatter sound like a bearing catching every so often. As for your issues had something similar in the breakin program where one side kept getting ahead of the other, but i reinstalled the program and it was fine after that, i have no homing issues or rapid just the noise no matter the speed and its not constant

Could you take a video? Could be so many things. The slats rattle, the chain link system could be making noise, vibration in lead screw. My Y2 rail had the pwd coat bubbling from getgo and make a crinkling noise everytime it passes in on section. So when your gantry came off rack, you restarted program or reinstalled FC?

Success! I homed machine and then adjusted the lead screws on that side. I could see the y2 gantry shift forward when I released the lead screw tension, and also when tightening I could see it pull. So I think I just had a combo of too tight and misalignment of sorts after I switched that aluminum bracket around (above post) and pushed my side rails in a tad. On y1 as I was tensioning the lead screw I could see the aluminum bracket pull in, so again just too much tension I think will create issues. I think that is what was causing the after home difference on each side. After homing I measure the distance between gantry and aluminum bracket on tube, I get 1 5/8.

I was able to come off home at 400ipm multiple times, I ran the hole table and no off racks. Going to be cutting monday I hope. I need an adapter for my torch fire wire. I’ll keep everyone posted.

sounds silly but are you rehoming after it off tracks? Put a level on the side tubes in back, middle and front to see if maybe your tubes are moving. I too noticed some of the V rollers being off all way back at home during my troubles. I check it constantly now. I loosen the bottom roller, then push on grantry as it wants to do a wheelie (Im thinking too much tension in the lead screws could effect that). So push with one hand and then tighten the lower roller till it touches rail, then secure the outside bolt. You could also crack loose the gantry all thread bolt and see if you can get it to resettle, then torque it back up, but make sure the bottom v roller is loose first.

i see you have resolved your issue, congrats. I tried to upload a video with no luck. The suggestions you talked about i have already ruled them out, although i did scrape off some of the poor quality powder coat that was bubbled up and repainted. This noise is definitely coming from either the step motor or the bearing inside the drive hub.

if you can upload to a youtube or something then copy the link that usually works. Id be interested in hearing it. Yes I think I should be good, just hope I don’t encounter a racking issue on a large expensive piece of steel!

I’ve been having this problem for the past 4 days and I’m happy to finally come across this post . Will try to fix my v rollers tomorrow

Hoping I get this resolved today lol . I gonna give plate to gantry distance another eight plus . And my rollers looks like it’s doing a wheelie too

I believe i have found the problem. The roller bearing inside the drive hub is rough. I disassembled the motor and hub, took off the ball nut and removed the flange holding

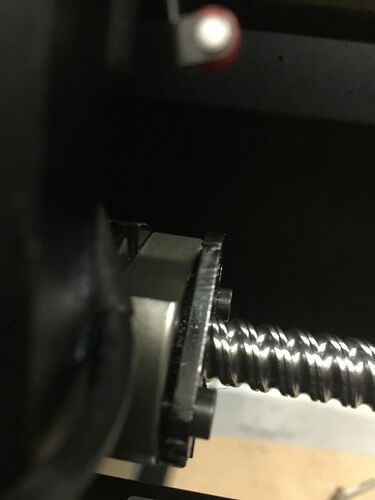

the bearing. By spinning on my finger it actually grabbed in one spot, so you can imagine how bad it could get rotating at 400 " per min. Also i want to point out , the guys that are having issues with the gantry going out of position, I discovered that the timing gears on the motor and the drive hub are not keyed and they are plastic. The only thing holding them from spinning is the nut on the end of the shaft, so if this comes loose or even slightly you could end up anywhere

I’n the case of the motor slipping how do you take that motor shaft apart I’ve tried and no luck

For everyone that had this problem switch your y1 and y2 cables and it should do the trick lol might of mistakenly connected on wrong place happened to me .

Glad you are getting to the bottom of things. Not overly excited about that pulley, one of the major parts of the system. Hope it will last. Iv pretty much always had two tables (one for back up). I have such little time for upkeep and was hoping the XR would alleviate things that kept happening to me on the Pro. I know tearing things down and fixing them makes it much easier to trouble shoot in the future. I ran my machine cutting for first time today. I made 1200 pierces and thousands of inches of cut. Spanned 5 hrs or so. Had a couple program issues and not use the directions of the slats for my tip ups, so took a bit to get use to. I cut some of my files by rotating them. Surprisingly my water table had no leaks, but I wish they would make them wider bc when you cut at the edge water gets all over. Overall decent day. I did have a racking issue early on, but I adjusted my lead screw on the one side and was good rest of day. I really want to get a scale or something and make the lead screws even tension as possible.

Yes that is def a simple and easy fix. Also make sure the X and Y1 limit switches aren’t swapped.

CrossFire XR Y-axis Binding motor shaft assembly.pdf (2.3 MB)

I have hilighted the procedure for disassembling the motor shaft components in section 8

I’m having this same issue after running my machine for the last 8 months. All of a sudden I cannot keep the gantry in position it keeps slipping/racking out of square. I plan to look at the v rollers but I’m scratching my head as to what else to look for.

Check to make sure your not encountering slipping along the axis that is failing to keep up. Check the 1 1/8" nuts that secure both the drive and driven pulleys on the motor and the ballnut respectively. Additionally, check the motor shaft coupler to make sure one of the set screws is seated against the flat, machined surface of the shaft, otherwise slipping at the coupler can occur. Any easy way to check for slipping is to power on the system so that the motors have holding torque. Then gently attempt to rotate the ballnuts by hand and see if any play is present, >1/32". If there is play perform the aforementioned adjustments. If everything appears to be tight please contact me weekdays, 730-4CST @9362353991.