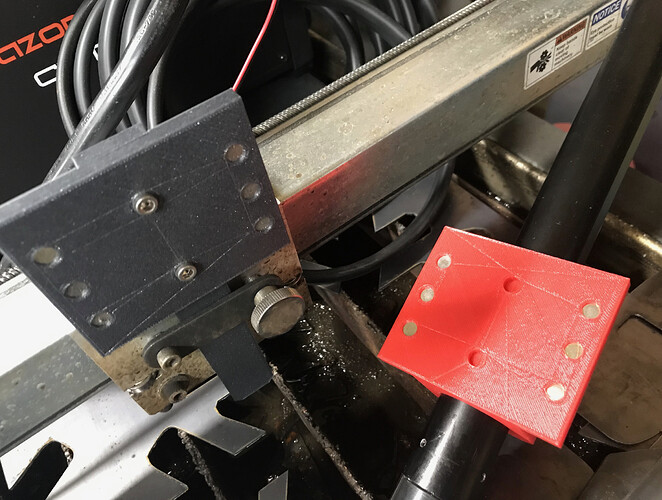

I’m super excited about my machine torch mount. I got my 3D version printed before I sent the files to the machine shop, and needless to say the files are on their way! Even made it magnetic so I will never have to use a wrench to remove the torch ever again. Can’t wait to get it back in aluminum and start using it. It’s incredibly strong, even in plastic! I’ll get some pictures posted as soon as the holder get back from the machine shop.

Why not just use the 3d printed one?Good idea by the way.

I’m more than likely going to attempt to run it this way until the other one get here. I had to print another Z axis mount because a made a few slight changes, but the printed holder will hold up now, but will not hold up over time. Even made out of plastic, I was surprised how sturdy it was though.

I like it. Very clean.

Was wondering about something like this myself. Any way of incorporating a “stop” control into that? Curcuit break or something?

I thought about that. Still need to do some thinking on how it would work, but I think it’s a possibility.

What torch are you using? I was thinking a straight one would be better.

Looks like a trafimet Autocut S45 in the pictures and that is a straight body torch but his first photo has the stock hand torch in the background so kinda confusing.

It’s an s45 machine torch. I just picked it up a few weeks ago. It does not fit in the stock holder very well and so I came up with the magnetic mount to mount it. I’ve been using a handheld torch up until this point. I was able to make a few cuts with the 3D printed mount (since I’m waiting on the aluminum one to get back from the machine shop) and even being plastic, it worked really well. I take some videos tomorrow.

I found the torch for $430-$485. I guess I’ll be sticking with stock to start.

I sell these torches. Hit me up if you want one

That looks amazing. Did you do the 3d cad? Did you stop the print to insert the magnets?

It’s been on my todo list to make one of these myself but my list is never ending lol

I will say that I’ve seen some table manufactures use a 3d printed torch mount and other 3d printed parts

How much do you sell them for?

I’m working on a magnetic mount for the handheld torch as well.

I pressed the magnets into the print after it was finished. You make a really good point about just printing them. I think that at this point the PLA that I have it printed with will hold up for a short amount of time but I think that I’m going to print them in ABS or PET-G and could sell them to guys MUCH cheaper than having them machined. Either of those materials will hold up just fine in this instance.

The only question about the mag mounting. What do you do when it pops off while lit? Maybe wire a micro switch in series with the trigger wire?

I’ve thought about that, and it would not be too hard. I’m going to do some testing with it this weekend to see what kinda of force it would take to knock it off, but I can tell you between the alignment pins and rare earth magnets that I used to hold it together, it’s not easy to pull apart, let alone just bump the torch to knock it off. Doing some testing will prove my theory though.

It looks real nice and sturdy, I’d just let it fly. Pretty neat to see it printed and utilized. I have seen printed metal but it was a ultra expensive machine of course.

Do you sell Machine Torch for the Vipercut.

Yes I do, send me a pm

Here’s basically the same thing with a wired e-stop for tip ups.

Edit : I talked to one of the owners yesterday and they have a new magnetic version that is wired like the electronic version they currently have on the website. That electronic version is being phased out in favor of two magnetic versions; one w/o e-stop and one w/ e-stop.