I purchased a machine torch for my everlast 60s machine. I drew up a 4"x4"x1/4" test plate with circles ranging from 1/4"- 1" a 1" 6 sided polygon and a couple of slots for dialing in my settings before cutting the real deal on 1/4" plate. I cut two pieces and noticed some slight beveling on the exit side of the circles and edges as if the torch wasn’t square to the cut surface. Long story short I started Dick’in around with the torching mounting trying to get it perfectly square and I clamped it in the wrong area of the torch body resulting in a no arc situation. It was causing the electrode to bind and there for no blowback action was happening. This maybe common knowledge or not, at least not to me, but I’m gonna put this out here anyway. Some machine torches don’t like being touched a certain way, so if you end having any machine torch issues with no start, this maybe something to look at. I’ve attached the trouble shooting guide I got from everlast on this.PTM60 Machine Torch Test Guide.pdf (475.4 KB)

I have the 62i Everlast Plasma…this is so true…also make sure your post flow is set for 30 seconds…

it is better to run air then to have to replace the torch head if it over heats…very easy to do…and the little sucker is over $130cdn…

now something to look at and test for bevel is the swirl ring…which side of the ring goes up can make a differance…and direction of cut…clockwise…counterclockwise…

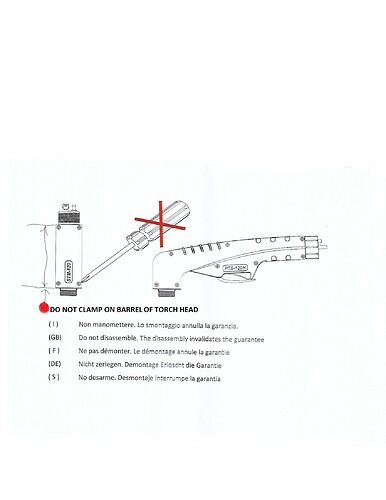

You never a machine torch by the retaining cup or the torch head only on the fiberglass barrel.

I put this sheet in every machine torch box I sell.

Toolboy,

so which way is the right way? clock wise or counterclockwise? there is definitely no up or down marked on the swirl ring haha. just have to look at the angle of the holes I suppose but what Is the right way?

also thanks for all your input all over this forum, very helpful!

I always recommend you put the swirl ring so the air swirls to the right CW. But if for some reason you are having some cutting trouble you may want to flip it over to CCW and it may help.

There is no so called right way but swirling to the right CW will keep the electrode from coming lose. Swirling to the left CCW can unscrew the electrode if it comes lose.