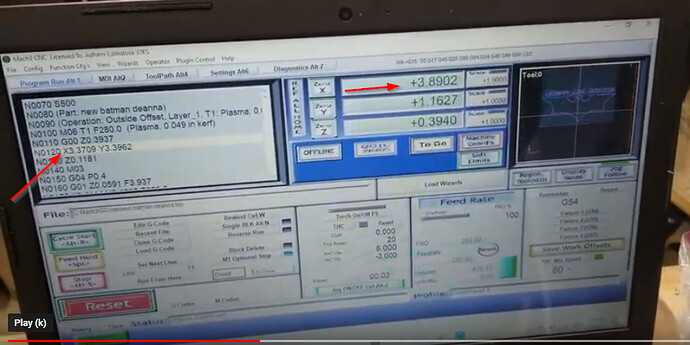

When I start a cycle in mach 3 the image looks good I am home in the bottom left corner. Everything looks good. When I hit start. It runs off the image and cuts it on a slant till it bottoms out the screws. I have a video. Here is the link. https://youtu.be/x2Ktwag0M-s

One of the easiest ways that I know to share a video is by using youtube if you have that setup. Otherwise you need to add the .dxf to the end of your video and select it, but many videos are very large and I’m not sure what file limits they have set for this forum.

Are you setting your orgins to zero when you align your torch to the bottom left corner? Not sure about the cutting on a slant, almost sounds like the gcode has some rotation built into it, depending on what your video looks like.

I edited the post. Thank you. https://youtu.be/x2Ktwag0M-s here is the video

I am only able to watch it on my phone right now but what is that pop up box asking when you hit the start cycle?

I don’t get any pop up box like that when I start.

Maybe place it in the lower left corner and hit the zero all button and see what that does?

Hi, what are you using for design/set up? Fusion ?

Soft limit warning. continue? Is what it looks like his pop up says.

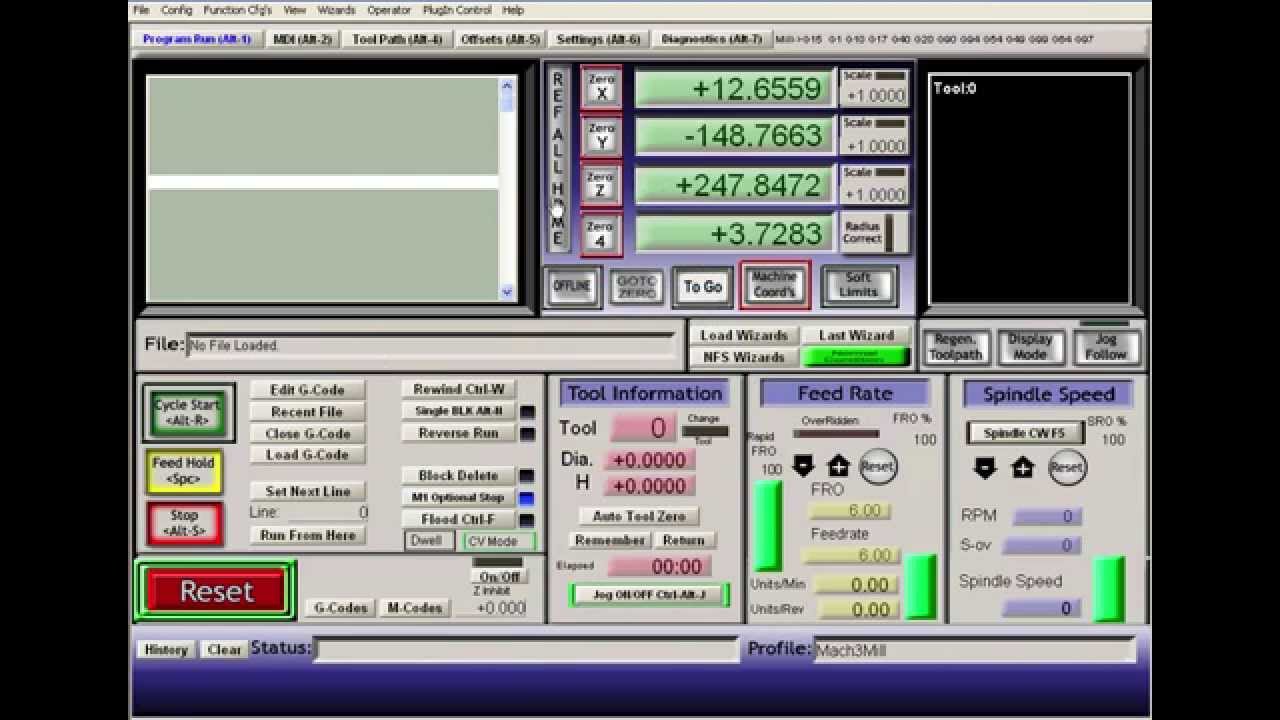

I’ve never seen that, I was just wondering if his machine home buttons are set at something other than zero? that’s why I asked him to hit the zero all?

What do you think? post processor maybe?

I would regain tool path , after i made sure lead screws didnt slip and was tight. And the table cordanance was where i wanted it. And the pop up I have never seen so no idea about it. And I think it could have something to do where the project was placed in the begining. Last time I had an issue simular to his vid: I was manually jogging and bottomed it out and didnt regain tool path. A few things it could be. I dont think it will be hard to figure out, but still a real pain. At beginning its all zeroed out in vid. After watching it again I see the image is in the upper right corner. Mine is always in the middle.

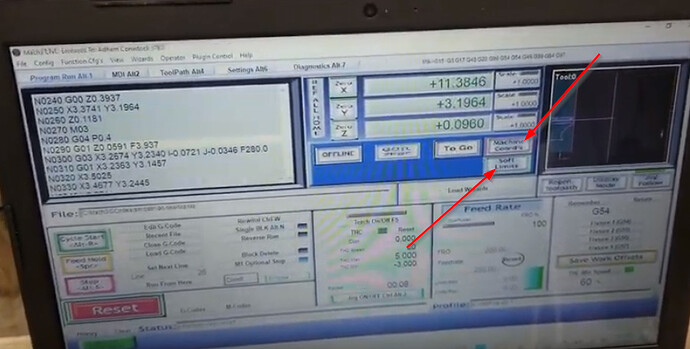

Whats weird is you machine command is telling it to go to X 3.37, and it’s already past that number in your DRO, which started from Zero… There also seems to be a common number in your program… 03937… Which is used to convert metric to english and vise/versa… All my programs have a units code in the beginning, I believe G21 for Metric, and G20 for english… Not at my machine at the moment so take with a grain of salt… I’d do as stated above… set your corner to 0,0,0 on the read out in your lower left corner, then hit regen toolpath and see if that helps… The softlimit error is in Z which is one of the 03937 errors… seems to be a small tip to material distance anyway, but shouldnt effect your machine taking off in X and Y… You can also set Zero, and manually jog the machine around and select jog follow to see what that looks like… On screen vs. at table. What is M06??? I don’t use that at all… Just M03 torch on, M05 torch off…

M06 is a tool changer command… Delete that line from your program… What post are you using? I’m suspecting not the right one… It appears the first command is to go to your toolchanger and grab tool number 1… That may be your problem…

Inkscape. I have reset home and zeroed the machine

One other thing… It looks like a green light is lit up around your soft limits button, so they are active, click that button to turn them off, that will probably get rid of the error if you have never actually set up your soft limits… Also it looks like there is a red light around your machine coords button. I can remember but I think that is lit when you are looking at machine coords… so zeroing the machine coords is not actually zeroing the programmed coords… toggle that switch…

Here is a zeroing video, but shows the state of the DRO based on the selection of that button state…

I would agree that it won’t help him with his current problem but the M06 was a great tool for me to learn how to use in the beginning, and even now since my wife always wants the intricate jobs cut, like the tree of life. It has allot of opportunity for tip ups and I ruined several pieces by it crashing into the tip ups until I learned how to use the M06 to my advantage. I don’t have the z axis and using the M06 gave me the option to manually jog the x or y in any direction after each cut and remove the cut piece out of the way then hit the cycle start and it would go to the next cut and never loose it’s place. It does take longer but it is a better option for me than cutting 3/4 of the project and then losing it’s position because it crashed into a tip up that I didn’t get out of the way in time.

We can save that for a whole new discussion if anyone is interested in how to use it.

Yea. I have my soft limits set at 23. And when it runs my program it will cut one section. Move to the right about 5 in. And repeat till it bottoms out the screws

No. It is all zeroed in the corner

I use inkscape and sheetcam

It’s a soft limit warning. I have it set at 23 inches. But the table will cut a section. Move approximately 5 inches to the right. Then cut another section till it bottoms out the screws.

Dwalls definitely interested in how you use M06

I have a theory, but agree it would be worthwhile having a new thread on the technique.