I’ve had the pro for 2 months now, and no luck with any settings. I keep losing the arc with every cut.

I have the THC installed, is there a way to adjust the torch height, to lower it a bit? Already was in contact with Chris from Razorweld (I use a Razorcut 45) he was very helpful thus far, thanks for that!

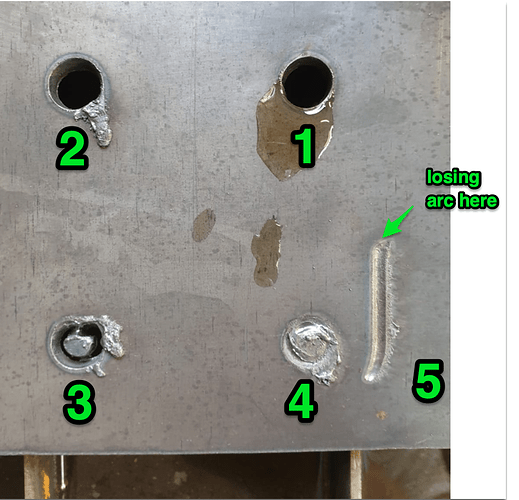

Please see the following picture

Thank you for your insights!

Greetings from Vienna Austria

I’m not sure why you would want to lower the torch height. Plasma cutting is very sensitive to height. You can adjust where your torch sits in the z axis but your cut height should be the same.

What’s your air supply like? What happens when you try to cut by hand?

I talked to Razorweld and they said the torch hight might be too high and that only the initial arc fires but not the cutting arc, does that make sense to anyone?

Thank you for your time,

Best

If the torch is that high, your cuts wouldn’t get worse with each pierce like in the picture. If your torch is touching the material with each IHS, then it is working as designed. What CAM are you using, fusion 360 or sheet cam?

The cutting arc is definitely working if you’re cutting those first two holes.

I suspect air supply is your issue. Tell us what size compressor you have and what your filter setup is.

2 Likes

Hey Brownfox, I use fusion for CAM and firecontrol for using the CNC table.

I have to admit that my compressor right now is still a little too weak, it only has a 50 liter tank (13 gal).

As of now, I don’t use any filter.

The new compressor is ordered, an oil less system, my hopes are, that with that new compressor I get better results.

Best,

Christopher

Your problem is air supply. 13 gallons is no where near what you need to run a plasma cutter.

Most of us are running around 5HP compressors with 50+ gallon tanks. Or running two smaller compressors together.

I cut for a while by hand years ago with a 30 gallon 175 psi 1.7 hp compressor. Had to wait fir it to refill on longer cuts.

Also, with no filters or cooling on your air, you’re putting terrible air through your cutter which will kill your consumables quickly and give poor cuts, even if you had enough air to begin with.

Go back to the drawing board and research compressors. Do a forum search for compressors, there’s plenty of info out there.

1 Like