I have exactly 1hr29m16s of torch fire on this machine and 1hr was today on cutting a 1/2" plate for a weld table. I have had to contact support 4-5 times now over this machine and I am really getting frustrated. A few weeks ago I tried to cut something and could not figure out why the cut was so terrible and spent countless hours on it until the support tech logged into my computer and after a couple of hours it was determined that a limit switch was creating noise causing my THC to go haywire while cutting. I bought a bag of these pieces of garbage and replaced the bad switch with a new one. Now I am cutting as only one would expect to be cutting on a $6000 plasma table only to get 45m into this cut and started noticing I was not cutting through the steel…AGAIN!!! After ruining $50 worth of steel, I found 2 more of these garbage switches are leaking voltage AGAIN, AND NO ITS NOT THE SAME ONE I JUST REPLACED… Does anyone know where someone can find a switch that can bolt onto this pattern that isn’t a 2 cent switch and might last more than 5m or do I have to pull this entire gantry off and redrill holes to fit a switch on it that may work?? Yeah, I am a bit upset since this is somewhere around the 5th time I have had issues since I have bought this thing with 1 freaking hour on it!!

I know you feel like you bought the item (limit switches) then you might as well get some value out of them. I added the limit switches earlier this year and that is when I started having changes with my cuts. Interesting. Don’t know if it has any correlation.

I will say that I was getting lots of warnings in FireControl when I had the soft limits enabled. They have been removed for 6 weeks and I am loving it. You are making me thinking of unplugging my limit switches entirely.

You could try to just unplug from the electronic enclosure and use the table without the limit switches like all of us did up until Dec 2022. You might to happier in the long run.

One wonders if the circuit is too sensitive with the limit switches. Might need to put in a small resistor and or a diode to help cut any noise on the switch legs.

McMaster car maybe? or google search limit switches.

I have not had any problems with limits so far. Did you get just one replacement?

I know there not easy to get to once the table is assembled.

Sorry to hear that you are having issues. Have you checked electrical harness at switches to make sure not chafed from rubbing and connections are tight? I have over two hundred hours now on my XR with no issues.

DC voltage is pretty tolerant of water, but computer control systems hate it. …And we put the switches awfully close to a water source and compressed air blowing on it.

Thanks folks for the reply. There is zero doubt it is a switch because you can click them and the voltage goes away in the THC Live Voltage. You can literally by 10 of these switches for $5.99 on Amazon and I used the exact same link Langmuir gave me. So the issue is now, sure, I can change the failed ones back out again OR go to a switch that was made to get wet. To get a better switch the bolt pattern now will change and it will be a very difficult process to redrill all these holes to fit them.

Yes I have ran this table probably for a 1/3 of its life with the limit switches un plugged which I personally think is a bad idea but don’t think I have a choice unless someone has found a switch that will fit this and is not complete trash.

There no possible way others are not having this issue?? I would love to understand why a limit switch can create this kind of voltage on the THC control unless there is physical water inside the switch??

The only other thing I suppose I could do is turn off the THC but that is a pretty expensive option to not use any longer.

Odds are high that you have another latent issue going on that you don’t know about. The style of limit switch that is on these have been around for decades. It is simple and reliable.

When you were talking to Tech Support, did you check ground to frame, computer, controller? Checking for voltage where it should not be when the torch is running?

I wonder if it not that you have abysmal luck with the limit switches, but that is the point where the stray electricity is getting into the system.

I have a XR and have had no issues, but I don’t use mine near as @rat196426 does.

If I could not get a switch that would bolt right up I would try replacing all of them with some of the cheap ones and see what happens (unless you have done this already) you may not have any more trouble unless like @Sticks says you have another issue.

Yes we looked at everything. We couldn’t figure it out at first until I just accidentally clicked a switch and the tech was watching it on his computer and just happened to see the voltage go away. I have this entire table grounded to a rod 6’ in the ground. Again I can unplug the harness and the issue goes away. I can replace the switch that is creating the voltage and the issue goes away. Maybe I just had bad luck with switches but I just cannot imagine that. I am almost certain (never 100% with electronics) that I have no issues with noise.

The facts are that if I go and replace this switch, I am certain the issue will go away…

I am not convinced this ebox should not be sealed either but I have not seen any complaints with issues.

I would somewhat agree with this except, an example is I have a large CNC router table that I use. I had to change out the limit switches because of high frequency vibration when I was cutting large pieces and it would trigger erroneous faults. You cannot use a 50c switch that is getting splashed and abused for a safety switch. Maybe for a small 3d printer your 100% right.

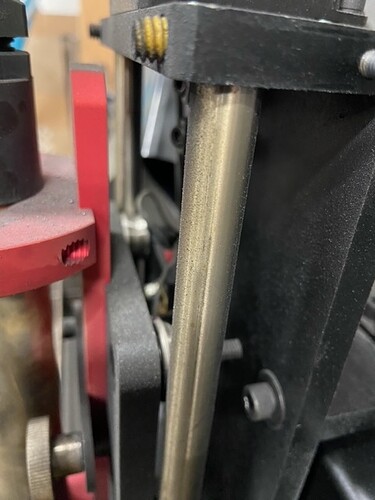

So I wanted to share something else I found for some of you having cut issues. This is just something to look at and probably maintain. I notice the head would sometimes not always but sometimes be way to high in the cut and after I started probing, I found a chunk of rust in the roller of the Z carriage. When the head would come down to touch off the part that piece of rust from the roller would lift the carriage off the seat and THC think it hit the part but it was a 1/2" away. Just something to look for.

I have to agree with Sticks here. You mention there’s another CNC router table that had similar issues with limit switches. Chances are very good something else is going on. One thing I’ve learned working on X-ray equipment is, low voltage if not properly grounded, cables not shielded against high tension cables, or cables coiled up wreak havoc on low voltage sources. Just my two cents.

Wow that sure seems rusty for what little use you have on your table

Wow that sure seems rusty for what little use you have on your table

Your starting to see my concerns. The post it rides on started pitting. It is something I will start checking periodically from here on. I coated them with a syn grease to hopefully avoid this.

You mention there’s another CNC router table that had similar issues with limit switches

I maybe shoulda sorta have been a little clearer. My point was it had the same clicker switches on it and they are not meant to be used in these types of applications unless it is like a 3d printer type thing. I replaced them on my Router table well over a year ago and never had the issue since. If I did have another issue why would replacing this switch make the problem go away. Same on the Plasma table. I replace the switch and the voltage on the THC goes away until another fails again. I totally get what your saying but I truly believe another $1 for a good switch would cure the problem.

I finally put another hour on it yesterday with zero issues except for the roller having a rust issue. So now I have a whapping 2.5 torch hours on this thing.

Looking at the pic with the amount of staining and corrosion that you’re getting on the rollers and table what kind type of coolant you’re using? Perhaps you’re getting corrosion inside the limit switches or connectors to the limit switches. I would try spraying contact cleaner and squirting some dielectric grease on the connectors. I’ve seen switches used for wet environment that have rubber push buttons and sealed bodies but they will be too big for this type of application.

ok so you have replaced all of the limits. have any of the replacements failed?

Is the table working now or has one of the replacement limits failed?

Do you see other rust issues like whats on the Z axis?

you might try WD-40 as it displaces moisture

I dont think that was me

Did you replace with the same switch? or did you upgrade?

I know your frustrated but if you want people to help, keep focused on getting it fix and less on stuff like this. This just turns people away

This is the first we’ve heard of this issue, we’re definitely interested in a resolution. I’ll be sure to bring this up with the team on Monday, and we’ll run some tests to see if we can recreate the issue.

I’ll keep you all posted!

Maybe we can run some solid state proximity switches, most come with small din connectors . Just need to determine if they need NPN negative switching or or PNP positive switching.