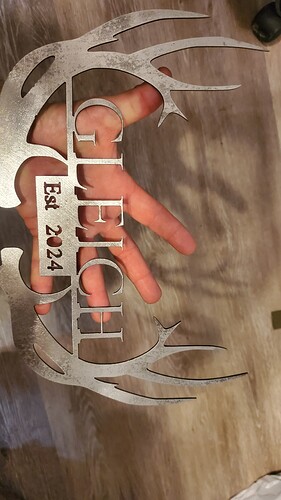

I am having a problem trying to cut small letters they are about 0.8 inches tall and are not cutting super good. It seems to be the cuts are stoping short but not for sure. Is there any tips to help this?

The stitches look great.

I see you have a divot in your hole that holds the ornament.

What cutter are you using? Are FineCut consumables available for it?

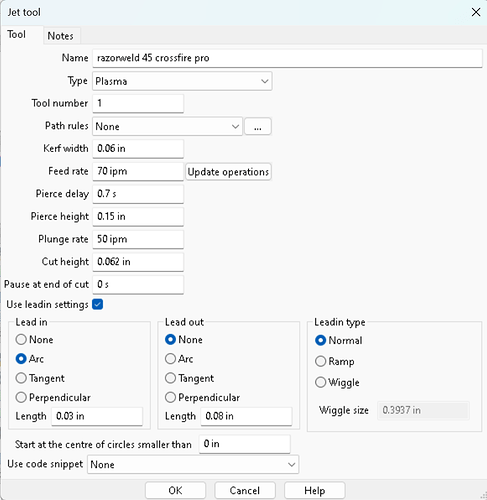

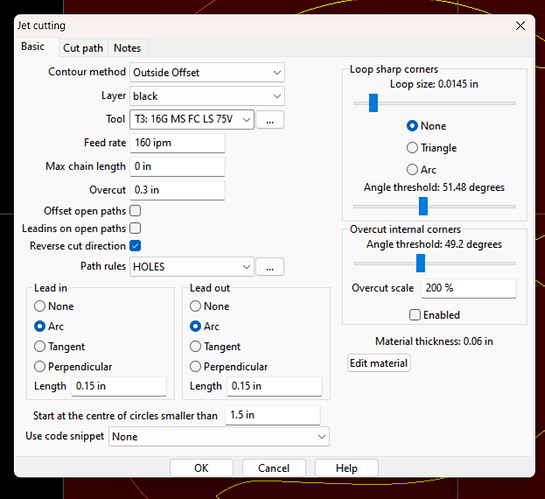

Please share a screen shot of the CAM (SheetCAM or Fusion) that shows the lead-ins/lead-outs.

Please share the nc or tap file.

They actually look pretty good for something that small.

It looks like you aren’t using a lead-in, though. That is why you have the divots on the edges of the letters and the hole at the top.

We are using the crossfire pro with the razor weld 45 with machine torch. No, we cannot get the Fine Cut consumables available with it.

Here is the screen shot of sheet cam. But it wont allow me to share the file on here.

Here is one I just tried to cut tonight. It seems to be the pierce because it starts moving before it pierces the metal. And not sure what else is going on. The letters are the worst part of it you can see the parts left in it.

Ok thanks my lead in setting is posted below I am using a 0.03-inch arc lead in. Thats the largest I could go without throwing an error

I would reduce the kerf width setting and reduce the pierce delay slightly.

My testing showed that my kerf width was more like .045". I doubt your actual kerf is .06" unless you’re running a 1.2mm nozzle.

Going with a smaller kerf setting(as long as it’s the actual kerf width) will also give more room for a longer lead in/out.

I would try a .5 second delay, unless that results in errors.

You could also benefit from a faster cut speed, but you would have to add some path rules to slow down for holes and tight curves.

I know it doesn’t make sense but they say if you have a divot, it will be reduced if you have both a lead-in and a lead-out. I see that you have “None” checked for the lead out.

I tried this the other day and it made a big difference.

I will try this and see. We are just using the consumables from Langmuir.

Ok. Do you just use the arc lead out as well?

Yes. Do the same numbers. David would have an idea of good numbers in SheetCAM if your .03 radius with 0.08 length does not fit.

Ok. What about the loop sharp corners? Do you use this? And if so, what setting do you use.

“Sharp loop corners” only work for the outside corners in Fusion (sorry, I don’t know SheetCAM - David will correct me if it is different in SheetCAM). You would not want that in the lettering.

I have not used it.

These are my settings in sheetcam. I never change lead in/out, sometimes I will get an error saying it won’t fit but it will still cut.

That is interesting because those lead-ins would not fit on many things that I do with Fusion 360 but SheetCAM finagles to get it to work.

@Madisonk , another thing that people will often do is find lead-ins fitting if they allow SheetCAM or Fusion do the CAM with a larger image and then shrink it when you get to FireControl.

How think is your material?

Also I will try to get to my computer and get a screenshot of my settings

I use Lead in [ 0 ], Lead out [ 0 ], Pierce Clearance [ 0 ] (kerf)

I also use Finishing overlap 0.4

Im using Fusion 360

The lower case letters on the name placards are 0.8".

The capital letters in the placards is 2.25". The large sign with the antlers the “s” in Est is 0.8". The big antler is 36" wide 24" tall. The smaller set is only 9". 25% of the orignal.

In the P Millis the “i” 's and the “s” are 0.75" tall.

We are using 14-gauge metal.

Ok that’s good to know thanks.

Everything above I cut was 14ga.

I run my speed at 120" to 140" per minute. I notice yours was 70 ipm. I cut 11ga (1/8) @ 80ipm.

When you go to slow it just sits and melts the metal. The arc will search for ground and keep melting the metal. Thats why one side has more slag then the other side of the cut.

In fusion there is an option to slow the ipm aroumd corners. I used to click those settings and my corners where always burned out and lots of slag.

Im used the razorweld 45 plasma cutting I have my amps set to 42. (Only because it was recommended to not run the machine at 100% all the time)

Also if you have a pair of calipers. Measure out 0.03". You are going to see its such a small distance is not really changing anything. This was my conclusion after researching and reading other peoples troubleshooting.

RECOMMENDATION take lead in lead outs to ZERO. Increase your inch/minute to 120ipm.

Also do you have Torch Height Control?