Those are so small you probably won’t see them in the print

I am just thinking when I try to modify the body, those facets mess up selecting a particular plane or surface.

But in this instance, that actually looks pretty smooth. I was just wondering. I know a lot of people talk of modifying a mesh in “Blender”. I might need to check that out.

I know it cost more but i like wall control pannels.I print hooks and custom hangers.

I use tinkercad alot.Imported stl files are easily customized.

Sorry @ChelanJim - I have not done much in the way of meshes and tweaking them for printing.

I’d figure out what the thread pitch is (looks like a DP, not regular screw thread), and go from there.

Maybe a mesh section sketch of the mesh body, offset plane through the middle then trace the thread profile, then a revolve to duplicate it?

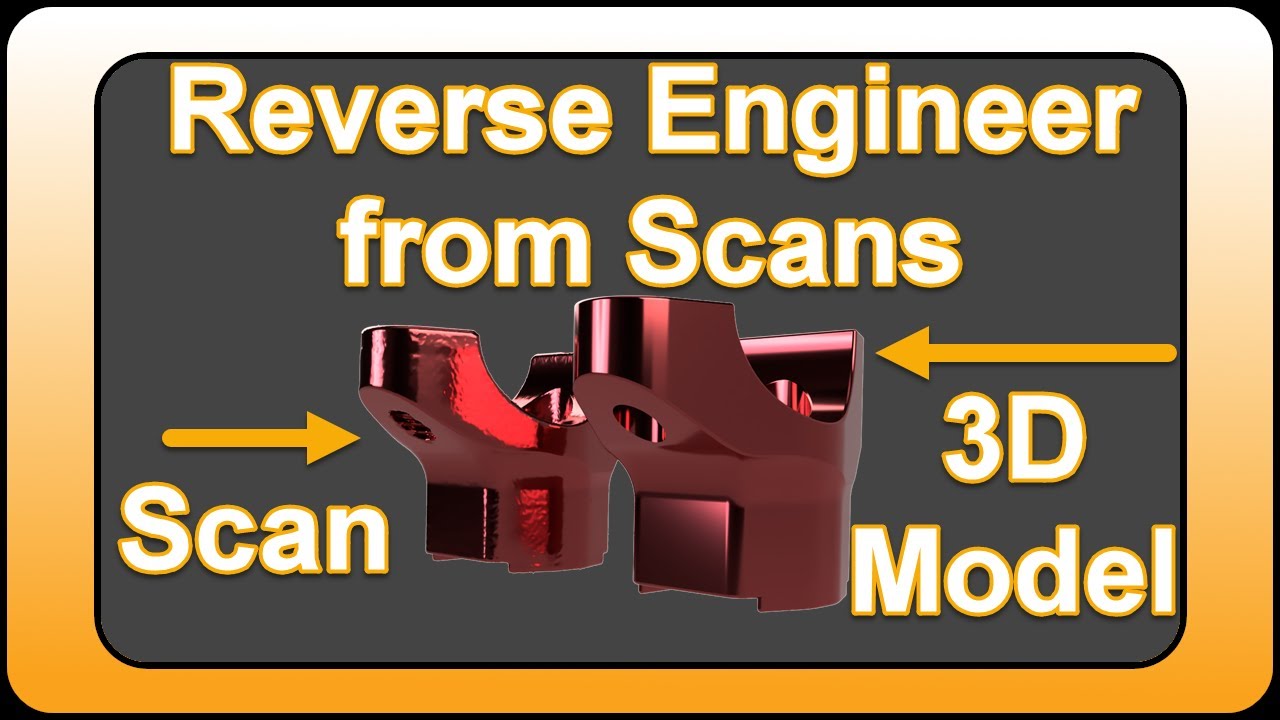

ETA - Look up reverse engineering 3d scans. Same procedure that I use when I work with scans of things. ex -

I did a sample modification in TinkerCAD. Boy, do I feel clumsy in it. Lots of learning to do.

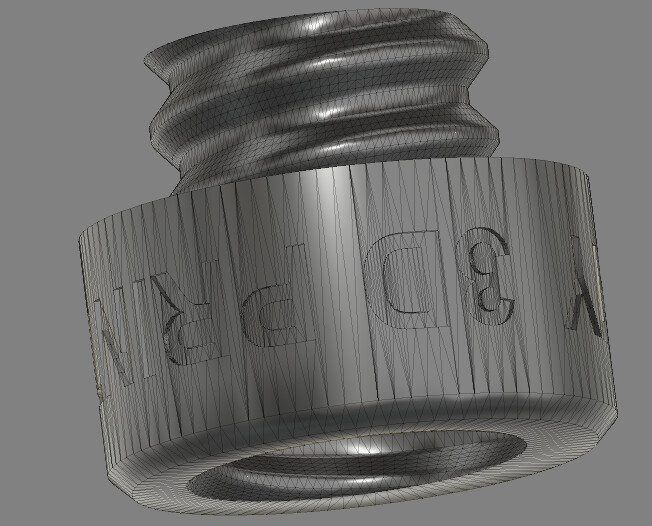

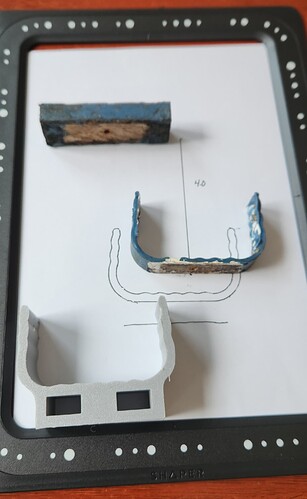

This:

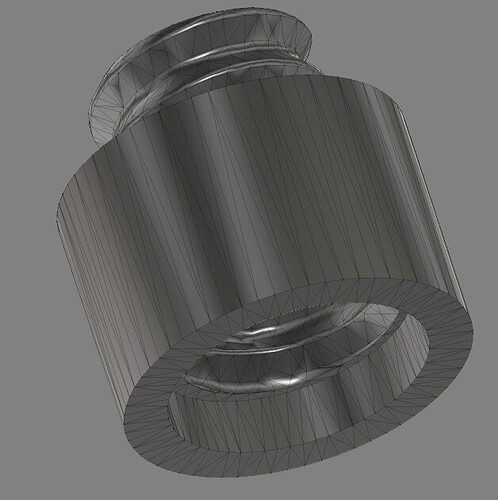

To this:

@Sticks I watched that entire video. Very good!!!

Thanks Sticks! Finally got a chance to view it (18 minutes). Good information.

Today I proved the value of my 3D printer and Shaper Trace. I have a deck roof structure that started rotting on the ends (exposed most to the weather and lacked adequate flashing) and the middle (poor design and lack of adequate flashing).

[I need to add: This was a project that my wife hired out since I did not want to work with 1/4 thick safety glass overhead. It has 13 panes of glass and 7 of them are 2’x6’. It has been here since about 1996. I removed most of the rotted wood and internally supported some of the remaining structure with a Bondo product meant for wood restoration. And installed flashing that will prevent the damage that originally happened.]

Now to my project today. The gutter had an intermediate downspout that traversed past a hand rail. Due to the handrail and the deck, the downspout needed an offset. I originally used the vinyl clips for this vinyl downspout but only scabbed on some wafer board as a standoff mount. It was purely ugly but served a purpose. Today, I said “This will be changed.”

I pulled out the Shaper Trace and copied the original clip, and the printed product that is quite robust, in comparison:

Here is the actual installation:

It grips so tight that there is no need for the side screws.

Looking good. Do you mind if I ask what material you decided to print it in? PLA for quick and dirty, and replace when it stops doing the job? Or something more UV and heat resistant like ASA?

Which Bambu printer are you running? I’ve got a pretty new to me X1 Carbon and a 9 year old Lulzbot Taz 5. Like you I find the Bambu printer pretty great, but I have 12 years and 2 hobby class machines of experience from before I got it (my first machine was a PrintrBot Simple in 2012, and I’ve had brief time using a couple generations of Dimension printers at the local community college) so I can really appreciate the speed and creature comforts of the X1. I finally decided after using the X1 that remote control of a printer was a nice enough thing that I bought a Raspberry Pi 4 and setup Octoprint for the Taz. This is the touchscreen and printed case and mount I made to put it on the frame of the printer. Printed in 2 colors of ABS-GF.

I don’t mind at all. I really had poor luck with PLA so I avoid it like the plague**. I used PETG since it was the color my wife wanted. It matches the caps that I put on top of some posts. It won’t be exposed to too much sun…no direct sunlight. I do have a fresh box of Bambu gray ASA but I am waiting until I really need something strong.

Printer: Bambu Carbon X1 with two AMS units. Brand new this year.

Wow. You have lots of experience with those printers. I am sure glad I learned 3D designing in Fusion 360 because that helps with a myriad of prints that I have done.

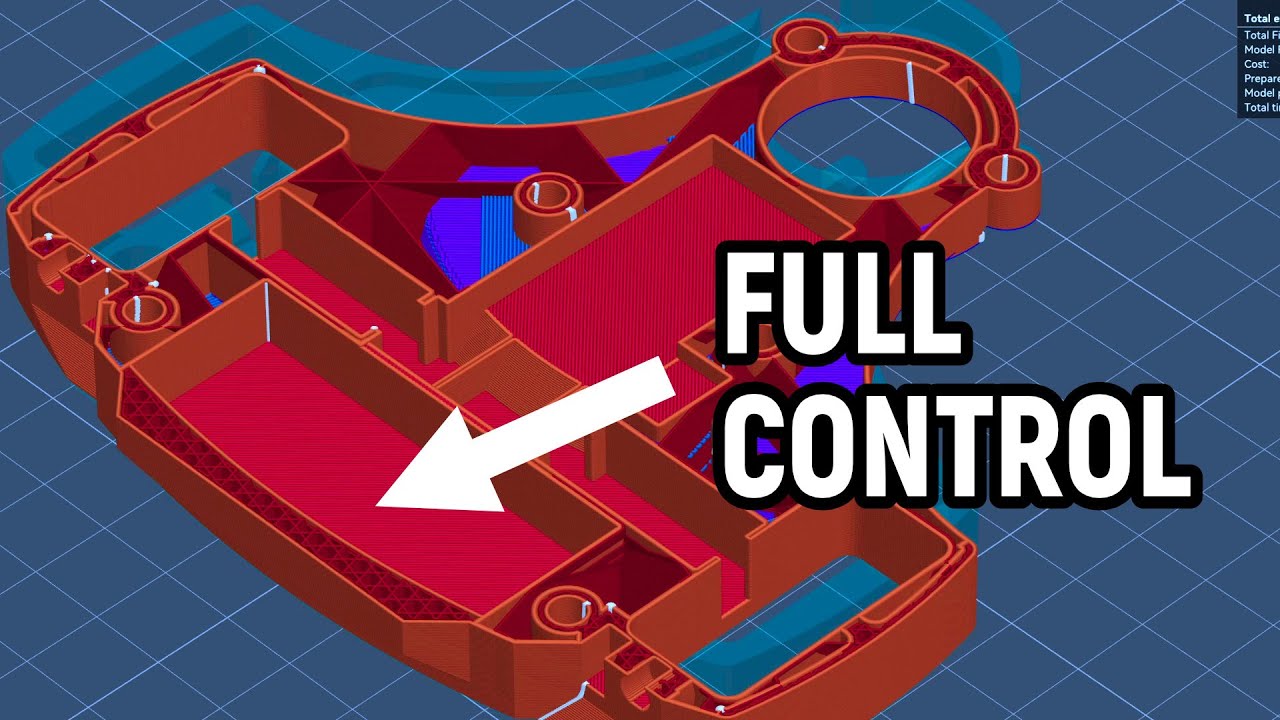

I thought I was getting good prints but the video that Craig shared about printing the outer before inner certainly improved things. You guys have probably known that for a long time.

**PLA issues: I kept having the layers separate. I don’t know if it was wet, printing too thin of a layer or what it was. It basically was one roll of PLA so I shouldn’t condemn the entire group of PLA but I have had really good success with the Elegoo Rapid PETG. It has a bit of a flat finish and is cheap. I have also had really good success with FlashForge ASA. I have had some varied issues with Sunlu PETG (70% good, 30% poor…usually it is when I venture into the 0.16 layer height. If I stay at or above 0.2 it is fine otherwise: spaghetti time). Also good success with ABS but it shrinks more than I care for and has a habit of lifting off the build plate if the heat is too low. The Sunlu ABS really varies from roll to roll with the bed temp.

Jim,

I finally just used up the last of my elegoo petg and will never buy it again. Every single spool would bind over itself and halt the print saying motor overload…it was so annoying. You haven’t had an issue with this? I have several other brands I’m using and I have had this issue with none of the others, only the elegoo and it was every single spool

The first one had an issue but after that, I always transferred to a reusable spool and make sure to clip the end of the roll that is tucked into the spool. Never another issue. I have purchased more than 40 spools and printed at least 30 spools of it.

You are not wrong about that warning.

PETG is a good choice for what your needs are out of that part, and cheaper and less nasty to print than ASA.

I’ve found PLA to be dead easy to print. I even found a partial roll of 12 year old white PLA in an old box when I was clearing out for the X1 and even that produced a couple fairly decent prints against all odds. It sounds like you definitely got a bad roll or something, because inter-layer adhesion on PLA is really good compared to most filaments. (PETG has great inter-layer adhesion too)

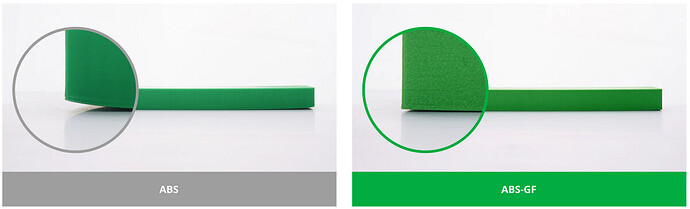

I loaded up on the Bambu PLA and transparent PETG while it’s on sale. Considering getting more of their ABS-GF while it’s $28 a roll as well. I’m really impressed with how it looks and prints and it holds up as long as you’re not putting tension between the layer lines, layer bonds aren’t as good as PETG or PLA.

Outer walls before inner can definitely help clean up a print, but it will reduce the overhang angle you can print since there’s no inner wall to help stabilize the outer wall over the overhang, so make sure if you’re pushing the limits on overhang angle to change it back.

I used Fusion 360 a bit years ago (and AutoCAD was the first CAD software I ever used), but I was using Solidworks for 3D CAD before Fusion 360 and when it came down to it i was just faster and more at ease with Solidworks so that’s what I’ve stuck with.

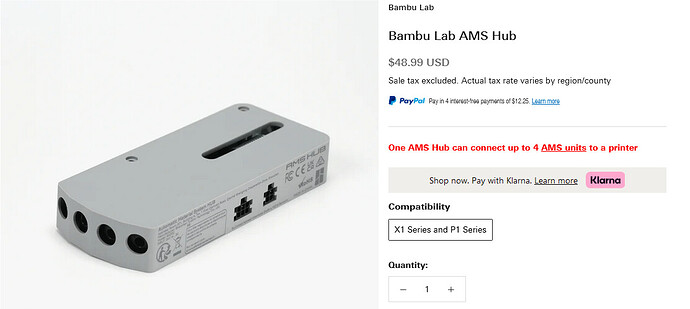

Have you had any hiccups with the pair of AMS units working together? I’m thinking about getting a second one. I’m happy with the performance of the one I have now (besides the extra time it takes if it’s printing lots of layers with multiple colors) though it’s still pretty much new.

Nozzle temp too low, speed too fast. Maybe wet filament, but most likely the first two.

Was it the BL PLA that came with the printer?

I am glad you have mastered the PETG. I won’t use it for anything large. Only special things that need the flexability.

ASA, or PLA+ for me. I have yet to use any GF or CF filaments.

I am not a fanboy of any particular brand, but Sunlu, Esun, and Duramic are my main buys, and no problems with any of them.

Yes, so true. I have my printer isolated in a room attached to the garage. There is no way for any fumes to get in the house. I wear a respirator when and soon after printing with ASA. Some say the fumes are less than ABS but other reports say “it may be less with ASA but the health risks are worse with ASA.”

Agreed. I have since printed some wonderful things with PLA. This pig is of another roll of PLA but I had to print the door three times before it was successful.

I was quite inexperienced when I had those printing problems so who is to say I would have them today.

I really like that finish. Never tried it. But, even in their listing they show this:

I don’t like that lifting even with the ABS-GF. ASA doesn’t do that.

That makes sense. Thanks for the information. I will definitely remember that.

I wasn’t trying to promote Fusion 360. I was just saying that having some competency with a 3D modeling/design program greatly enhances the use of a 3D printer. It is rare that I print something that I don’t find I want to modify some aspect. That is why I have gone thru so many spools of filament.

None, whatsoever. The biggest concern was getting this part as it kept being back-ordered. I would get notification that it was back in stock and within less than 10 minutes from the notification, it was out of stock again.

I highly recommend the additional AMS unit. It is great to have all those slots for various filaments and having room for a spare roll waiting to fill in on a print when you are using up the last bit of the roll of a particular filament.

Presuming you are in a low humidity area. Desiccant packs can only do so much, and those AMS units are not airtight.

Probably.

No. It was Sunlu. But, I have also had some issues with a roll or two of Sunlu PETG. But I also had at least 4 rolls of Sunlu PETG print without an issue. I have not messed with the speeds that come up with the generic settings. Still trying to understand the volumetric number. I did change that a few times especially on the Elegoo Rapid PETG. I think I am in the sweet spot with that filament now. For those who might try it, I saw someone point out that it has an issue with clumping during the first layer. They recommended to make the first layer with the bed temp @60 degrees C and all other layers @65 degrees C. That has stopped nearly all issues with failed prints with that filament.

I like both ASA and PLA+. Like you, I have not tried GF nor CF. David pointed out that there is a layer adhesion issue with those fibers being added. That worries me. But I know Tin has had great success with CF. I think that is what he uses with his torch pointer. My attempts printing something as delicate as that pointer failed nearly every time along the layer lines with PETG. Again, as I mentioned on a previous post, I think the PETG prints that I have done that failed was trying to do the 0.16 layer height with a 0.4 nozzle.

(Note: I shouldn’t say the prints “failed.” They looked perfect but if I attempted to bend them, they would easily snap.)

I have used Sunlu ABS, PLA+ and PETG with good success. I like that it comes on a plastic spool. I have not bought any ESUN. I have used Duramic PLA and PLA+ without any problems.

I will not buy anymore GratKit spools again. It is not because the filament is bad but they have two or three different size cardboard spools that don’t play well with the AMS unit. Switching them to a reusable spool requires an adapter spool to fill in the space of the hub and in also an thickness disc for the entire spool. Too much monkeying around for me.

I keep an eye on the humidity monitor that the AMS unit has. I have a 50 gram Dry & Dry wedged in the space between each filament feeder and a 20 gram pack in each pocket in the base of the AMS. When that monitor hits “3”, I swap those packs out for dry ones. They seem to last about a month before I need to do that swap.

Note: I believe that monitor is in the base of the AMS on the left side because once I replaced the 3 larger packs that were between the feeders and it did not change the value on the humidity monitor. As soon as I changed the one on the left side base, the value dropped.