So I been running the pants off this PRO since sept. I cut alot each week. Lately Iv noticed my holes getting bad. Normally that is due to lead screws slipping in the couplers. So I usually jiggle all the bearings and holders etc. I noticed if I pushed on the bearing side of the X asis as it glides on the Y rails, I could move the whole X asis about an 1/8 of an inch even with the motors on. So I checked opp side and same thing. Well I have a brand new PRO setup right next to it, not even ran yet and it has zero movement. So I came to the conclusion it was the lead nuts.

I got new ones (still inquiring as to why I had to pay for them, machine is under warranty) anyway I replaced them and totally fixed the issue. Its very hard to tell on the old lead nuts that they are bad, you have to fully installed to check them. As I was dismantling them I wiggled them and they had no movement, but when fully hooked up you move the whole setup.

So just thought I throw that out there, check your machines often, things loosen up and or go bad. Also if anyone has any better ideas for lead nuts Im all ears. I found some brass ones on ebay but not sure if they are same bolt pattern. thread is the same.

I wonder why they had no movement on removal, but had the movement when installed. Seems weird. This is something I had thought about though, the lead nuts are delrin and with them being against the steel lead screws, I imagined it may wear out over time.

It’s called wear & tear.  When you buy a new vehicle they are not gonna replace the tires under warranty when you wear them out, right?

When you buy a new vehicle they are not gonna replace the tires under warranty when you wear them out, right?

1 Like

that explains the wear and tear…

I agree that derlin is not the best option…but it is the most economical price point option for a great low cost table.

$100 or more to go with metal…well that bings in a whole new set of wear and tear issues as well as upping the machine costs to manufacture…

1 Like

Warranty states ALL machine is covered for 1 year minus electronics for 6 months. Iv had multiple bearings go on my other machines, they sent me bearing packs. Yeah I get the wear and tear, but warranty says 1yr and it falls under that by months.

Im not saying they should necessarily sell them with better lead nuts, but Im saying is there a better option? For the little rise in price it would be worth all the headache with thousands of customers complaining about it. The couplers have been and issue as well. I get it with small price increase on high volume, but its not going to effect sales by raising price a little bit on the small stuff. They are priced very well. Im just trying raise awareness that if there is an alternative maybe someone can try out and share. Just like the couplers. I posted about ruland (muuuuch more expensive) but its an alternative.

I agree with you on most of this…

so what if a table goes up by a couple of hundred dollars…but often that price difference is a factor for some people…breaks the budget.

the other issue then becomes…where do you draw the line on “this part is better, and only costs a few bucks more”

then there is the other side of the coin…business profit and return…if they can save $200 per table with parts that work well for an entry level table…and you sell 100,000 tables…that is $20million in cashflow available for R&D…customer support…and return to the company to take to the next level…thus the XR was most likely produced at a faster timeline.

the real problem like I said is where do you draw the line…

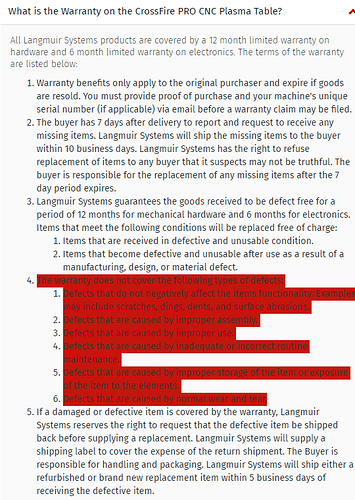

now as for warranty…not sure where you get “ALL machine covered for 1 year”…here is the statement for the PRO right from the website…limited warranty…

I have highlighted the not covered normal wear and tear…

1 Like

Like I said, Im not saying they have to sell it with a better lead nut, but seriously a PRO machine needing new leadnuts 9 months in, and not to mention cheap couplers that stripped long ago. Iv dealt with plenty of maintenance on these machines. I cut over 15hrs week on them hard, back to back cutting. There is no machine on the market that comes close to the cost and reliability as this one. SO that couple hundred more for better parts to me isn’t going to make or break a sale too much. Or simply offer better products as upgrades. They have scaled really well and with the XR that will be my 5th machine I’v purchased from them. Im loyal to this brand bc of their growth. Im not trying to tell them how to run the company, but if little things can be dealt with from reliable feedback, then I think that is helpful.

As for the warranty. the first sentence says it all. 12 month limited warranty on hardware. the only hardware on the machine is bolts, lead screws, nuts, couplers. The bottom where it states wear and tear is really just a loop hole that contradicts the first sentence. So you when a bearing bites the dust two months in, we can all agree that is covered or that is wear and tear? Lead nuts failed at 9 months in, running 15hrs a week. So running 40 hrs a week these things wouldn’t last but half a year. What is seriously going to fall under warranty if not under wear and tear, you use the machine once and its wear and tear. Just like the electronics, they need turned on and used and they are covered for 6 months, is that not wear and tear?

Most guys aren’t running these that long each week Im sure. I get it, they are fine for most. Just pointing out to be cautious of the looseness of machine. Im not trying to convince LM to change their production setup or run their company. The price says it all. Just like if someone wants to run a razor plasma vs a hypertherm, you aren’t going to compete in the long run, but you pay for what you get.

That is why I mentioned that bc it was weird. I thought I’d check the nut bf I took it all way off. By hand I couldn’t feel the play, but prior to taking off it had play on both sides. Once replaced and the play was gone, cuts were better.