It cuts realy good but sometimes I get a realy jagged cut. loohs like a sawblade. any help would be appreciated.

Can you post a pic of your cuts.

Also post the material type and thickness, and settings you are using.

Cut 60,14Ga,45amps. I don,t have any pics, 75ipm

I use a CUT60 as well. Seems a little hot and slow for 14 gauge. Are you getting dross on the bottom side of the cut? I think I use 30 amps and 100 ipm on 14 ga. Book setting for 16ga is 30 amps @ 110 ipm. I will have to look when I am home. I don’t have my tool settings here at work.

That’s very slow for 45 amps on 14 ga.

A couple of things to check.

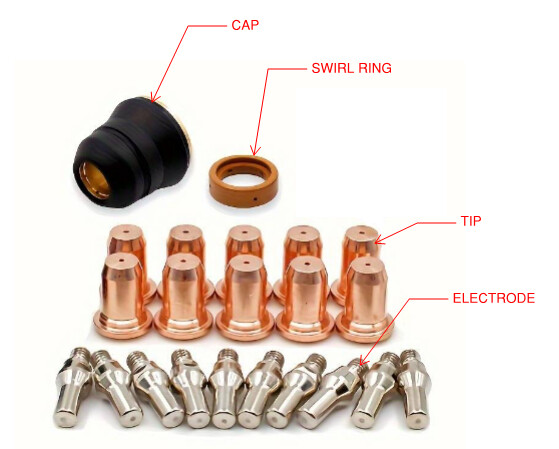

- swirl ring

- check for plugged holes in the cap of the torch

- check for any play in the Z or X axis carriages.

What is swirl ring ?

is that the piece that goes with the consumables ?

I did some interpolation of the PW cut chart. These should get you close.

14 gauge @ 45 amps 111 ipm

14 gauge @ 30 amps 88 ipm

A swirl ring is a consumable.

Gotcha, I figured thats what it was. I was having problembs with the Z axis being loose. It,s fixed now but still does it every now and again

How can I check the X axis ?

Grab the Z axis motor and try to rock it front to back.

If your swirl ring is good to go (new, and oriented properly) and the jaggedness is inconsistent from one piece to another, I would bet that the voltage is fluctuating.

I experienced it once, and it wasn’t until my friend experienced it himself (also using a CUT60) he measured the draw/voltage and found the CUT60 dipped down below what it was supposed to during its cut path.

The result, was a saw blade type cut like shown here -

You’ll see many areas are perfect and suddenly some jagged cuts, then perfect again.

Interesting, what was the fix?

He bought a Hypertherm ![]()

Bought a Hypertherm Powermax65 Sync

I’m looking at getting a Powermax 45 myself, just not yet

Did he warranty the CUT60?

He didn’t bother, nor did I as I’m 100% positive that’s the issue I ran across some months ago that no one figured out.

Not to mention, it’s one of those rare occurrences that gets mentioned in the FB group where not a single person’s suggestions helps and suddenly the author’s issue disappears.

I’m chalking it up to it just being a Chinese plasma cutter.

@72Pony you and I are pretty close on the Cut60 settings. I have 33amps, 98 ipm for my starting point for 14 gauge. My cutter is 1st gen and I’ve noticed that once a cut starts, the digital readout on the face of the cutter usually reads several amps higher the resting value. So if I set to 33, it would likely be cutting at 35-36 amps.

As for the jagged cutting, I have also seen it come and go. I assumed it was either due to some slight issue with lead screw stresses (temp in garage, needing lubrication, lack of squareness), or from the voltage fluctuation phenomena mentioned above. It has been rare for me, so I hadn’t worried about it.

I have also experienced the random serrated or jagged cut edges. This seemed to be more prevelant with the lower cut amps. Say 40amps and lower. After much frustration I came to the conclusion that it was the result of moisture in the air. Even thought I have 4 stages of air filtration, apparently the moisture was making it through. I started spending a bit of time draining my air tanks and making sure there was no moisture visible in the air each time before I started cutting. Since I started doing that, I have not had one single bad cut.