impressive

I use the arrange feature all the time. You have to mess with the envelope sizes and manually flip objects on the first tab to do that last little bit of maximizing.

Every now and then I will have to manually do it as a partial rotate fits things in better, and F360 does not do that.

I find deepnest is pretty good for oddball parts, but for square parts I’m better and faster to nest in sheetcam by hand.

Does anyone know if the crossfire non pro is able to add a driver for a slave axis? I’ve been thinking of redesigning my 2x4 table so the long axis is the gantry rather than the short. This would let me support both ends but still allow for pass through index cutting up to 50" wide. Its been awhile since i opened up my case and i dont remember

What do you mean by this? The original Crossfire used a Mach3 controller so, yes, you can have up to 4 axis on that board AND configure it any way you choose.

Right, but if they have been updated to have thc then it uses firecontrol. Or if you buy a regular crossfire right now it comes with firecontrol. My question is if they lock you out of being able to add a slave axis unless you originally purchased a pro. If it was mach3 it would be no problem.

By ‘Slave Axis’ do you mean a second Y Axis Stepper motor and Driver? THAT is easy. It’s just wiring and maybe a beefier power supply.

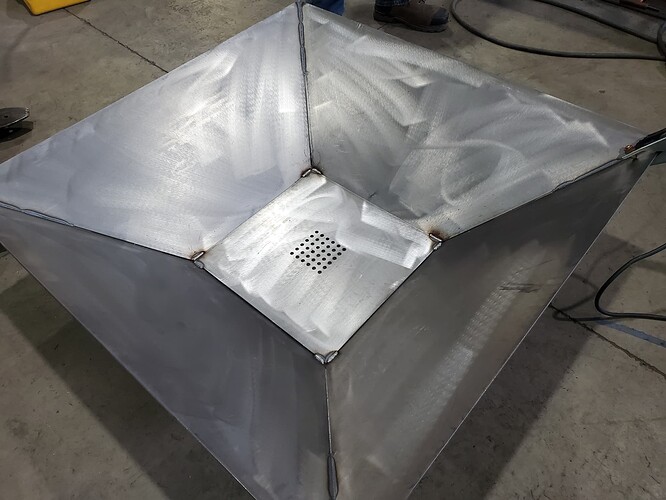

Yep. Basically want to switch my table over to be like this. Ideally I’ll get my driven nut system dialed in at the same time

So… does it currently have the newer Crossfire controller or the original one? If it has the new Crossfire controller, it already has the second Y axis driver in it. You only need to add the motor and mechanical parts.

Yea ive got the new controller. Ive swapped the other drivers out, but i couldn’t remember if it had one for the slave

I’d just buy an STV at that point.

Then I’d have to deal with selling mine.

Shouldn’t be hard; sold my Crossfire within a few days of posting it.

Ok for all us smart guys whats STV?

It’s a CNC table manufacturer - it’s the very brand posted in his above picture (the post I replied to).

Although I’ve never seen that small “Hurricane” they offer. I would skip that and suggest anything bigger than that from them.

But to add to what @MMFab mentioned, I must’ve missed any posts beforehand as I only replied to the latest post but I’m not going to lie and say I haven’t thought about switching over to a different movement style on my own table.

I love my CFPro and will keep running it as much as I do since it makes jobs easier (and makes plenty of money). But I’ll most likely buy another table before I ever really upgrade/change my own.

Ive played with a driven nut lead screw on my CF. It was way better but my design needs some fine tuning. My table is an OG CF but expanded to 50x24 lifted up for 6" of z height with the thc and firecontrol. I get some noticeable lead screw whip at the ends of the table. The driven nut I made like the XR was really smooth but I had some issued with the bearing and shelfed the idea until I have more time. I just really dislike langmuirs use of the square tube and roller bearings. I think an 8020 rail and linear slides would be a much better solution.

But yea, by the time I screw with that I might be better off upgrading tables. I always told myself when it was time to upgrade I would diy a 4x4 with a 3kw fiber laser.

My constraint right now is shop space. My shop is 60x60 with 2 bays, but I have to fit big equipment in there. Im already getting a hard time with hiw much space my fab-corner is taking up. Ive got a 18’ wide 16’ tall 2 ton overhead crane that rolls the entire length in my bay of the shop so I have to keep room for the heavy lifting jobs. It makes loading the table nice though.

Now I see the STV app n the pic. Thanks