I don’t really like it when guys make stuff look real nice, doesnt seem fair to the rest of us that struggle to just get something to work, let alone look good. ![]()

Well it certainly was a benchmark!

Truth be told, I really struggle making wiring look nice. I have a buddy who is TOTALLY OCD when it comes to nice wiring. ![]()

Ya I don’t like those guys either. ![]()

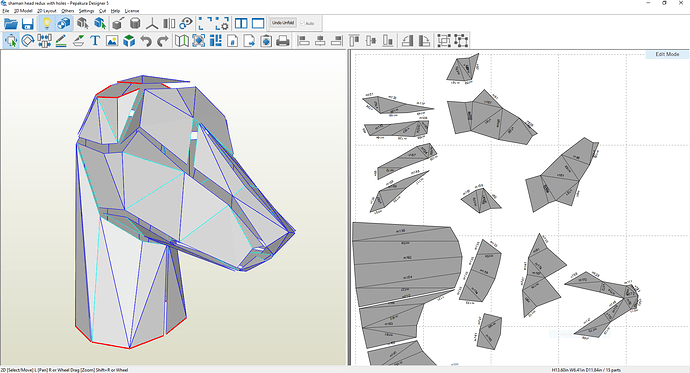

I’m back working on my garden shaman. The deer head I made last December was way to big but it was beneficial. I worked for a couple days in Fusion 360 modeling but its surface tools were too limiting. So I learned just enough Blender to move the vertices and edges around. Luckily, I created the quick build video last time because I used it again to split my OBJ using Pepakura.

Build video

I cut everything using sheetcam and 18 gauge cold rolled. Nothing new to see there. Then I started bending all the angles.

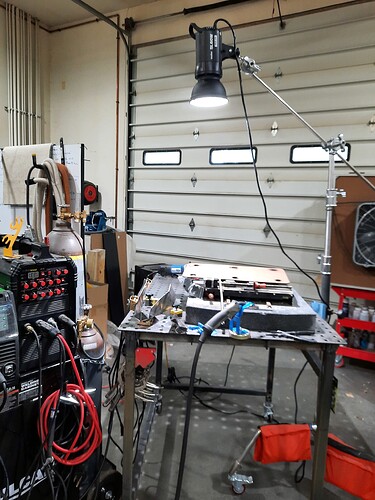

My tacking setup.

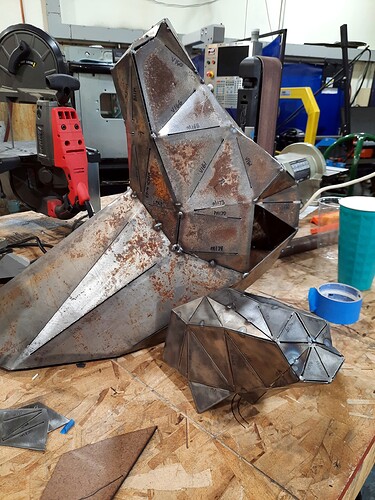

It went pretty well. I got his nose tacked together. Using that video light is the bomb for visibility! I was able to mostly tack him together from the inside. That’s quite a change from version 1.

You can see the size difference.

He’s going to be perfect. Remember, this is just his nose, I have to add his eyes and forehead next.

WOW! …That is really interesting! ![]()

I cleaned the dust off my plasma table to show that it still works. I blended my two favorite tools into the same project as I made a stand-off mount for the antenna/receiver for my new robot lawn mower. The mower is affectionately named “Tin2”. ![]()

The two parts (one from the plasma table and one from the 3D printer mated perfectly. The only problem I encountered is that when I projected my image onto a sketch for the metal plate, it was on the Z/X axis. Curious thing as this has never happened to me before. So obviously, Fusion 360 would not recognize the contour selection until I told it a bit more information.

@holla2040 I have that same Prime Weld TIG welder complete with water-cooled CK torch and my own reservoir/heat-exchanger. Thing is, I can’t TIG weld to save my life! My tries have met varied successes and failures and I have sort of given up. I think I will revisit it again from scratch. I so wish I could stack dimes and do those pretty TIG welds! ![]()

![]()

Will start by dusting it off today ![]()

![]()

![]()

I have the exact same problem. I’ve tried and failed at least 20 times to TIG.

Practice makes permanent. No one is good at tig at first, I know I wasnt good at all…but after I sat down and dedicated myself to making consistent welds (forget the instagram stacking of dimes and the fancy colors - which is oxidation btw) then I surpassed being just good at it.

Well said!

Totally agree Instagram and Facebook is where people show their best and hide from reality.

And Harvest your Personal Deets… ![]()

Let’s say that one of my many TIG challenges has made me a good tungsten grinder.

I also have that PW Tig welder. Been trying to learn how to use it. I have a hard time seeing what I am doing. I run to hot and slow most of the time. When I am not doing that it’s too fast and cold. I have spent more time grinding tungsten then building puddles. ![]() The trouble is when I burn through everything, I can’t grind it smooth.

The trouble is when I burn through everything, I can’t grind it smooth. ![]()

![]() I may have to talk @Phillipw into a vacation out west.

I may have to talk @Phillipw into a vacation out west. ![]()

Did I mention I cant see what I am doing. ![]()

Get yourself a cheater magnification lens for you welding hood. I run a 2.5x magnification in mine and it makes a world of difference in seeing what is happening.

Thanks for the tip! I am going to get one of those.

They work great. I use a progressive-style lens in my glasses. I had the eye doctor move the focal point up about 1mm so I could see with my head looking down. I fixed my problem.

Ordered a 2.5 let’s see (no pun intended) if it makes a difference.

It helps a lot. You can practice all you want, but if you can’t see what is happening, you’ll never get good results. You’ll be doing welds like this in no time.

Very nice indeed! …makes any difference if I start off practicing on aluminum vs steel? Aluminum is my main interest for TIG welding