Fooled around with LED strip backlighting last nite. The sign will be great for a couple of vintage car shows i intend to show my baby at next year.

Very cool, you’re giving me ideas… I’m thinking gun-safe here! ![]()

Nice combination! What wood and Stain is that? I like how the fire seems to feed into the grain. Well done!

I found this 24” round pine ready to go at Home Depot for $18. I just sized the metal for the wood.

Playing with colors earlier…

Hello! obviously new here and to most of this. Curious about your water table and fluids. I noticed you are using the expansive cutting fluid. Is it worth it? … and is it ok for it to be on top of the material? I read somewhere on this forum that the fluid shouldnt be on top and can harm the torch on the Hyper therm 45xp. Thank you in advance. Crossfire XR 4x8 with HP 45xp.

@MuthaCuppers Welcome to the Forum

I have a bucket of water that I literally dump on top of the sheet while I’m cutting for stainless steel to keep the heat down.

When I do end up upgrading my water table I’m going to have it set up so I can do some submerged cutting of stainless.

Water from within the compressed air is the enemy.

It sure doesn’t look like that for long. Buy some decent cutting fluid and just be done with it the expense is negligible compared to all the other expenses involved in this endeavor.

welcome to the forum…

Additives to water…well…

the 3 most common are Greencut…Sterlingcool…and home mixture of borax…

th additives do not affect torches or the metals…in fact the additves protect the metal from rust…

any plasma table with a water table gets splash onto the metal surface and this is fine as the air blows away the excess water.

I would say that additives are not expensive…the average mixture ratio is one part additive to 20 parts water. one pail will do over 100 gallons of table water…

I cut often and I can make a pail last 2 years…

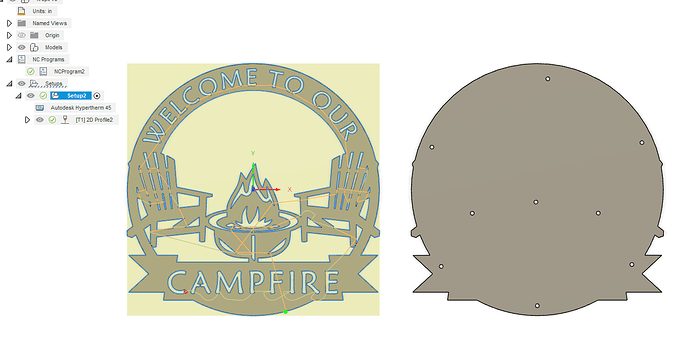

New toy! I’ll post some more details later when I use it to mark out bend lines on project. I haven’t decided yet what i want to make but I’m bending something! I used it on my last project for Campfire sign to make my drill locations for threaded studs for multi-layer sign. @davebogdanski made it and it’s pretty awesome! To me this is a game changing tool and allows me to really get creative and nto only use table for metal but many other things.

That’s how tool disease starts you buy a tool or press brake and really don’t have anything to use it on so you make up something you need!![]()

![]()

![]()

![]()

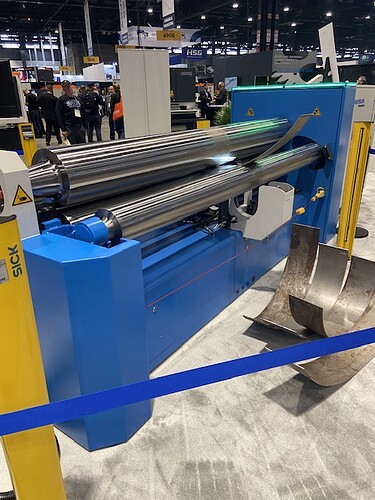

After you get a bender for the project. You’ll realize that the next project would look so much better if it was on a radius… Then a slip roller shows up at the shop doors! (ask me how I know ![]() )

)

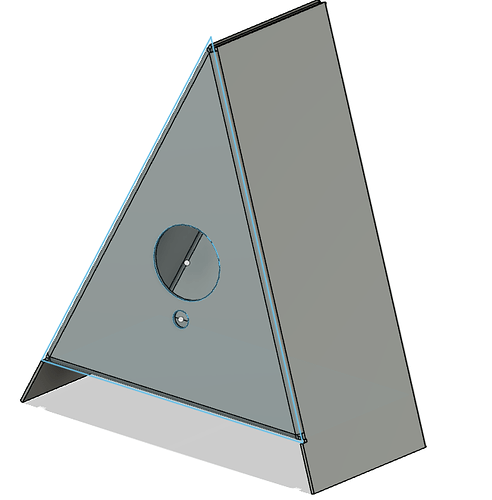

So, i decided to design a rusted-out birdhouse. I reason for bending something was to use the sharpie to mark my bend lines. As you can see their dead on and no half-moon or marks on design. Going to let it sit for little bit and really get rusty. IM @davebogdanski if interested in one. I have hypertherm 45xp hand torch. I can see me doing some wood designs on CNC using sharpie and carving them out. Lots of cool stuff this opens up doing and not just metal.

[quote=“maleybr, post:1084, topic:9910”]

radius… Then a slip roller shows up at the shop doors

[/quote

Small or big?

Now that is a roller. 32" fire pit x 3.14 …

Sorry, I was practicing.

I think the larger one of those two weighed 36K

Should roll 14 ga for a fire pit

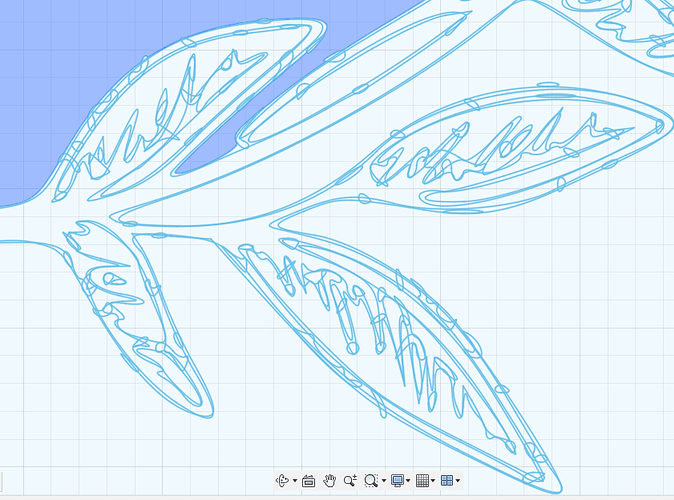

I had this logo that seemed quite simple:

Close-up of the image in Fusion360 reveals that there was considerable work to improve the image:

Final product:

16 gauge steel, 14 inches in diameter. Hypertherm 45XP, regular consumables, 30 Amp, 150 IPM. Spray paint finish. Center hole in top was located by using the “center of mass” of a body.

Those leaves look rough. New to some of the fusion 360 and was single click deleting until I realized I could select drag and hit delete key. However those lines were so close to edge probably still took forever.

One way to easily delete in a situation like those leafs is to delete two line segments that are part of the leafs and are far apart. If they are part of the same continuous segment, you can then double click at one end and it will select that whole line segment.

I am sure some of you will recognize these based on my never-ending questions on this forum. Thank you for your help. 16ga, Pro, Cut 60.