you are right and that is my dilemma trying to figure out which direction to go in retirement. I know I don’t want another full time job and don’t want time constraints of having to do something on a deadline, but I like creating things

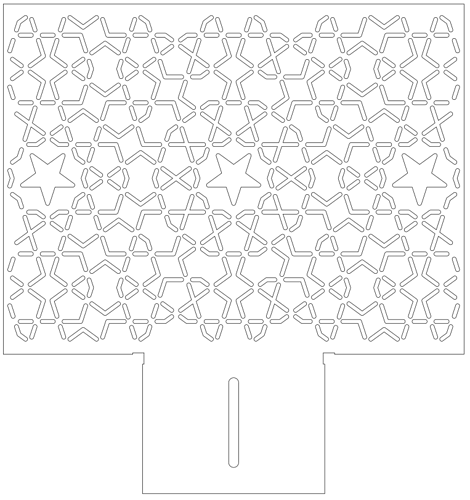

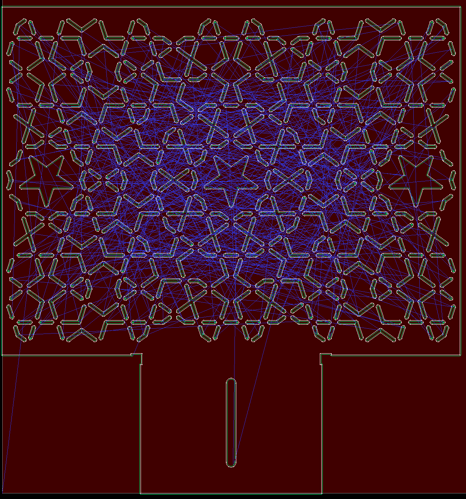

We worked on back porch light cover number 2 yesterday.

This is going to take awhile to cut.

Found a 18ga scrap at the metal yard.

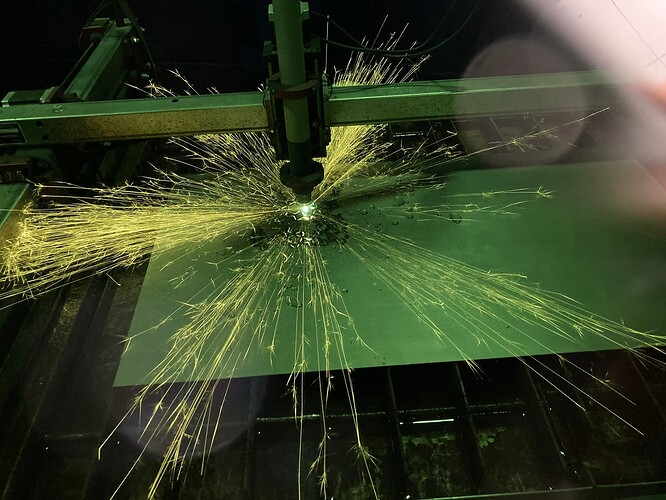

Started cutting

My sister and me

18ga was a little thin, had a lot of heat distortion even with stopping often to cool down.

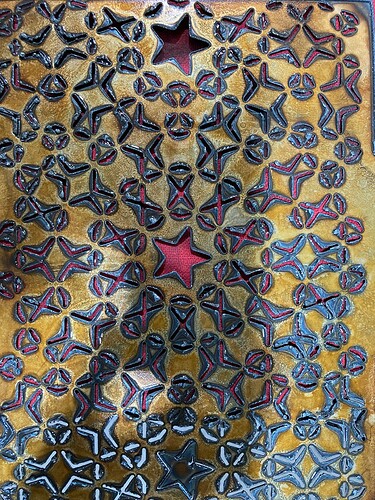

Cuts look just OK, Clean up went fast.

My sister choose Prismatic Powder’s Granite Sage.

Test run with a bathroom night light

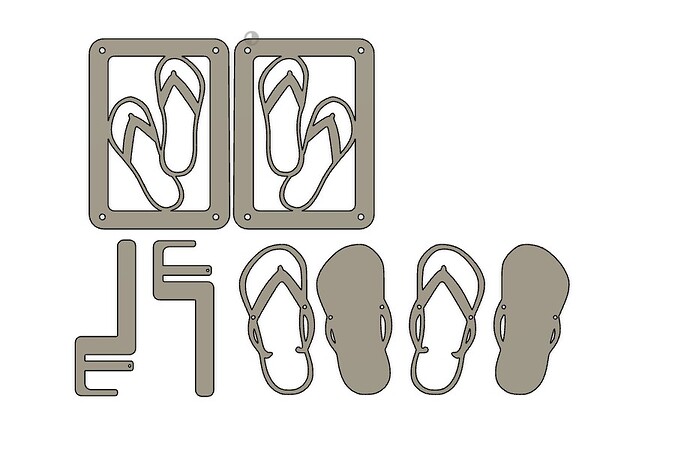

These didn’t go on my jeep. Sharing design, I made for friend of a friend over weekend. She was going to pay over $100 for these…smh

Jeep wrangler JK rear light covers and foot pegs | FireShare | Langmuir Systems

This is showing how they go in the hinge but you still have to weld the other design like sandals on this footpeg

My son is leaving for work in Colorado and might have to leave his new KTM dirt bike behind for a year. I made him this yesterday so he could take with him.

We did attempt one more copy of my sister’s lamp shade. I tweaked several plasma cutter settings and got a great result, super clean, narrow slits (0.08" wide). We also applied the powder coat a little lighter and got a great texture.

I’m using inkscape and sheetcam for this. This is made with 18ga, 333 pierces, 41 minutes. In sheetcam, I changed the cut path to “Minimise thermal distortion” with 7in between cuts and set lead in 0.04in. With a 0.8mm nozzle, I got super clean 0.08in wide slots. However, thermal distortion was so bad, I had an unfortunate stock drag while cutting the perimeter. Took 20 minutes to kinda get the stock back in position to complete the border cut. Its time to fixture my table for stock placement.

It’s a Jeep thing and I love it!

Built an engine hoist for the shop, turned out ok. Tested it to 2000 pounds so it’s plenty strong enough (it weighs 317 pounds, should be strong). Learned some hard lessons about heat and welding and warping…Videos are long so if you’re bored they’re a great time sink.

Part 1

Part 2

Part 3

Load testing on my old truck

Hitting 2000

Folded up for stowing away

I’m going to start a log splitter build next week, nothing fancy but it will be fun. I’m going to try and make it a much shorter video.

I have built several splitters. I made one with a dog leg to lift the wood so no getting on your knees and no lifting.

Fun project!

Nice work! I enjoy your videos, you are definitely better and more productive with your projects than I am with mine!

Your assumption on the strength of the tubes related to their strength in bending is wrong.

A 2x2x1/4 tube has a elastic section modulus of 0.75 in^3

A 2.5x2.5x1/8 tube has a elastic section modulus of 0.8 in^3

A 3x3x1/8 tube has a elastic section modulus of 1.19 in^3

So what does this mean… Considering moment capacity:

The 2.5x2.5x1/8 is 6% stronger and 1.5lbs lighter per foot than the 2x2x1/4

The 3x3x1/8 is 58% stronger and 0.72lbs lighter per foot than the 2x2x1/4

I’m being called to bed so I don’t have time to do the numbers but you will see an even larger disparity in deflection between the smaller thicker member and the thinner deeper member.

I’m sure what you have built is plenty solid but thought it was interesting information you would like to have.

Moment capacity= (stress x Section modulous)/1.67

You can google the section of any member… I have an app on my phone that lists them… or you can do the calc by hand.

That is actually fascinating, I would VERY much like to know what app that is! I was surprised how much flex was in the 2x2x1/4 legs, you can see it in the picture above when it’s carrying a ton.

I am trying to think how I would react in this scenario

Should I go to bed after being called or stay up and crunch some numbers? Ya I know what I would I have done ![]()

![]()

![]()

![]()

The app is called CSI Steel. It will give you the mechanical properties of different steel shapes.

I should have checked your members vs the plastic section modulus (Z)… I am a little old school and when doing napkin calcs I use S instead of Z as it is more conservative.

If you are interested, when I get a min I’ll look into it and go through all the equations.

Maybe just DM you so I dont turn what is supposed to be a project thread into a science project. ![]()

So when I want to design something structural and I have questions I can ask you?

Sure thing @Knick, I can help you. ![]()

good to know thank you!

Pretty happy with this. Biggest sign Ive cut yet. 32" circle. Cut out of 14 gauge. Cutting it for a realtor for a rental property of his. Next, powder coating time!

Looks great! How will it be displayed? Hanging or ground

Hanging. I cut 4 1/4 inch holes for it