@holla2040 that raw Rottweiler low poly is a very widely used low poly sculpture. There’s many Etsy sellers that sell it. Truthfully all the good low poly models that I’ve seen in the past seem to all come from Russian designers and I think a lot of them use SolidWorks. I used to have a really great copy of SketchUp 8 a with a bunch of plugins that could do this. It can be done in Fusion 360 if you’re very confident in the sheet metal environment. There’s also plugins for Fusion 360 but a lot of them are for paper models which don’t allow for material thicknesses.

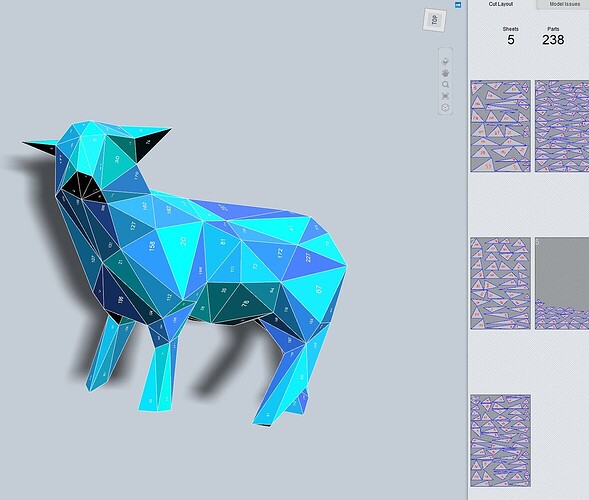

Here’s a workflow I did a little while ago of taking a 3D scan and then making it into a low poly model.