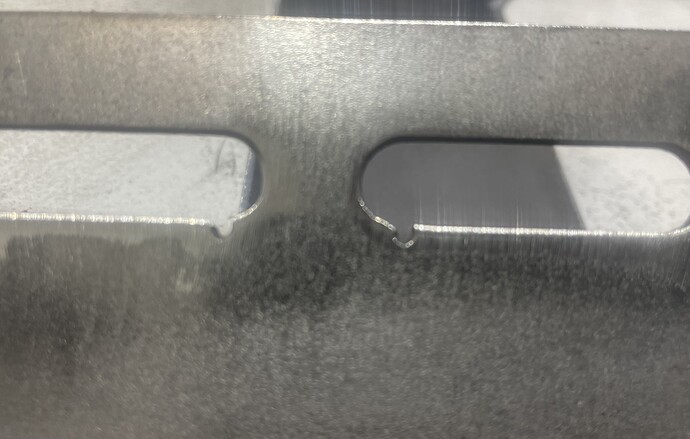

How to fix this issue these little start blowouts have a pro table with 45xp and auto torch head control

How do you have your leads setup? Looks to be cutting on the wrong side of the line.

That is a piece mark either you have your lead in and or out setup wrong or you are cutting on the wrong side of the line. Could be too long of a delay as well. What parameters are you using?

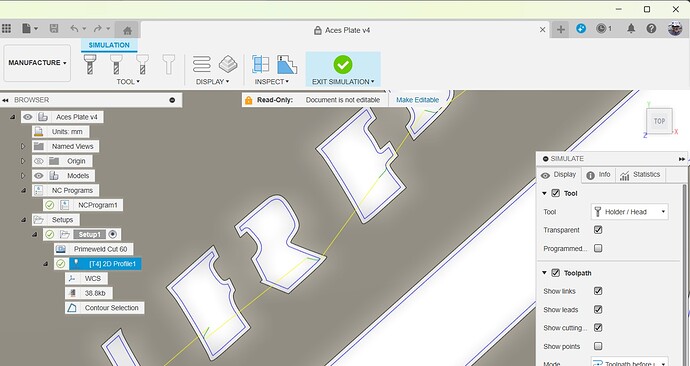

If you are using Fusion 360, in the Manufacture environment, under Actions, run the Simulation step. Look and see which side of the line the pierce and lead-in line are shown.

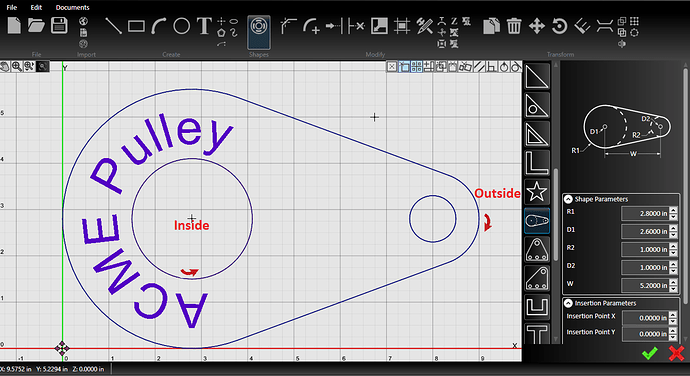

See the short, green lines INSIDE of my letters. That’s what you want to see. If not, you likely need to change the Sideways Compensation (see below) from Right to Left when creating the toolpath.

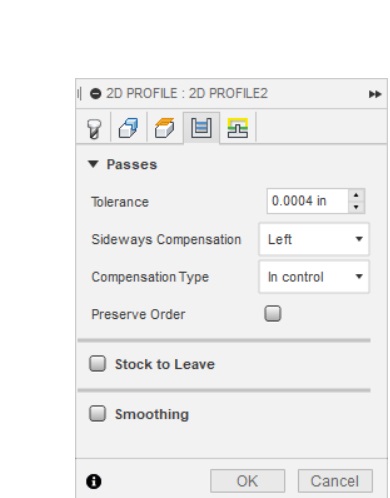

I’ve never understood this lingo/label. Why is it right or left? Why not inside or outside?

Because not all cuts are closed loops.

and not all start locations are specific to the left or right per that image, so how does it work to establish an absolute location for piercing?

It is referring to left or right related to travel direction as the torch is moving.

@apynckel Think of it as you’re in your ‘torch’ car, driving down the cut line. Is the line on your right side or left side?

MUCH better description! Thanks Tom!

Ah, but how do you know which direction things are going to run?

The car(torch) is always moving forward… you are behind the wheel.

If you are using Fusion 360, you can run the simulation. I believe SheetCAM has a simulation as well.

Certainly with Bret’s demonstration, the lead-in at an angle or arc will show you the direction as the torch is not going to make an abrupt turn-about (will NOT choose the acute angle direction) once it gets to the cut path. The only ones that might be questionable are the 90 degree lead-ins and when there is no lead-in.

A simple rule of thumb.

The inside diameter is cut counter clockwise, The outside diameter is cut clockwise.

Does that apply in F360 as well?

That’s a basic rule of plasma cutting. The “good” side of the cut is on the right side of the torch, as described in the car analogy above.

When cutting out a hole in a design, the cut should go counter clockwise. This puts the right side of the cut on the finished piece.

Cutting clockwise on the outside perimeter also puts the right side of the cut on the finished piece.

We should just keep this image around as the standard answer to which way. Its near perfect, great job with visualization.

how do you get the inside to go one way and the outside to go the other way. When i am in fusion 360 and i start picking lines that need to be cut it does them all the same direction unless i change it to right or left but it changes everything. Sorry new and this hard to explain