Hi all,

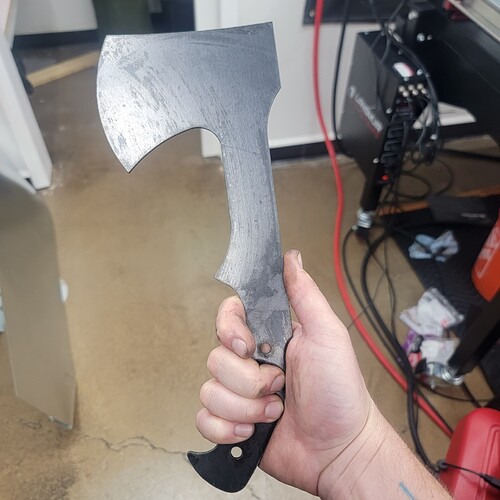

I’ve been getting more comfortable with my CFP in the last few weeks. I have a tool dialed in pretty well for cutting 10ga mild steel and have cut out some very nice looking products with it.

Today I began playing with 16ga mild steel, and went to add in a new tool to use with the thinner material. Unfortunately, I started getting errors right away and after some fiddling, I can’t really find any consistency.

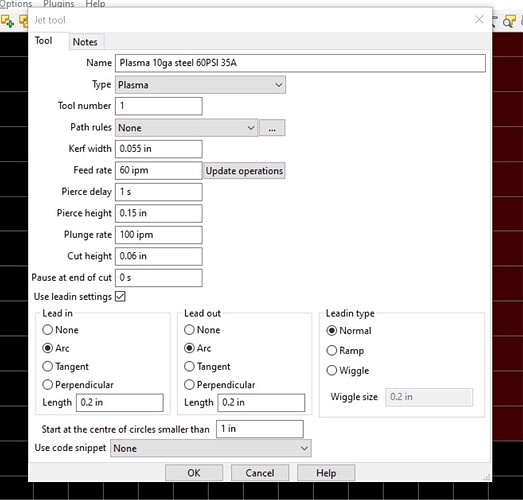

My original tool looks like this below:

I created Tool2, which is basically the same as tool one but it’s set for 100IPM vs 60 IPM and 30A vs 35A. Both were saved in Sheetcam and I simply processed the files with either tool and overrode the saved file (meaning I did not keep a file run with Tool1 AND a file run with Tool2).

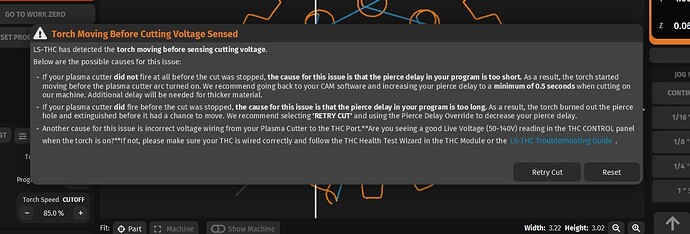

When I ran the post processor on my file using Tool2 (and updated operation), I got the following error:

No fire, not even a little bit. Torch fire testing were all fails. I tried some things, went back to the original Tool1, still nothing. I read something in my searching that made me turn off smart voltage on FireControl. At this point, the torch would fire and actually cut. I tried this a few times, actually having luck with turning smart control back on during a cut sequence. Odd, right?

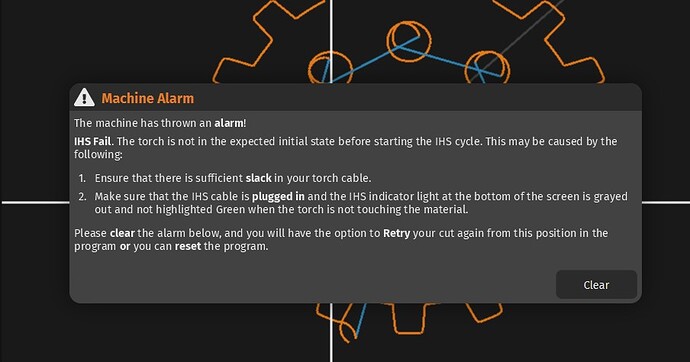

So then I tried Tool2 again, but now I’m getting the following error:

Unfortunately, I’m not yet knowledgeable enough to know what I should be searching or trying to figure this out of my own. Any thoughts?

Machine is a Razorweld45, using machine torch and whatever consumables came out of the box. I’ve tried starting cuts with smart control on, and off. I’ve tried deleting a tool from sheetcam vs simply selecting which tool to use. Not sure where to go from here. I

Thanks for any suggestions.