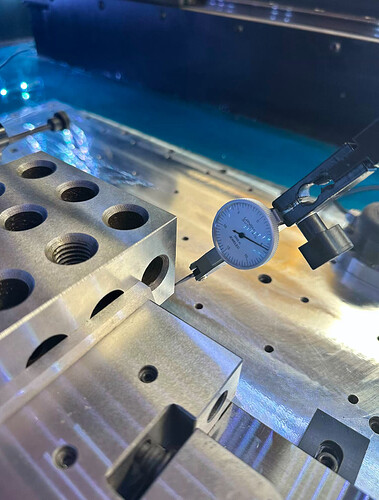

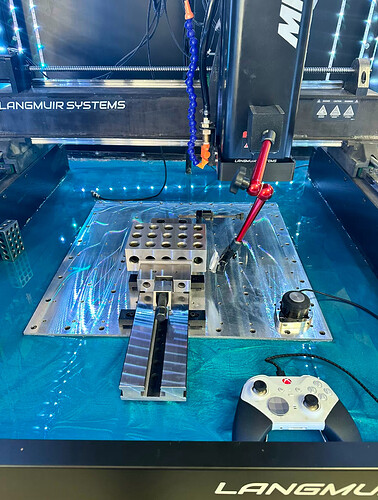

I am working on traming my mill and preparing to do so I am trying to square the z axis with shims I have already added 10 shims on both sides (10 on each side) on the bottom 0 on top. The dial is moving from 0 to 5 over 2” (top to bottom.) Not sure what to do next I am out of shims. Here is my setup

P.S. I started with 3 shims in the lower 0 in the upper according to the cards that came with the machine.

Its hard to tell, but are you indicating on the side of that block and not the front?

1 Like

Sometimes I am a dummy yeah I was using the wrong face did it on the right face and over ~5" I went from ~10 to ~8 that seem manageable still at max shims though

1 Like

Excellent. Yeah, its a super easy mistake to make, been there, done that. You end up focusing on the needle movement and not what the needle is actually reading.

In my opinion, dont worry about “max” shims. Add shims till its right, then go from there. If youre only two thou off now, a couple of extra shims wont matter. Having the Z axis fairly straight is important for deep drilling more than anything. If you have it straight, the load and vibration on the drill bit is negligible.

1 Like

The video on tilt is super confusing I got the nod within a tenth over 6" but tilt is way off ~17 tenths over 6" the video says add shims hit it with a mallet and vuala. Watching the video they left out add the gusset plates back in and assuming loosen the screws and bolts. Also they keep mentioning set screws but never explain what or where they are talking about. Long story short no clue how to rotate the head of the machine to fix my tilt.

You dont have to have set screws, they just make it easier to sneak up on the tolerance. I know some guys had a hard time, but if you keep a bolt snug its easy. Basically, just loosen the four bolts that hold the spindle into the Z axis, then snug the top right one (not super tight). Then what I do is tap the bottom left of the spindle gently and watch your indicator. After the indicator is reading the same on both sides of your plate (all the way to the left, all the way to the right), tighten your four bolts and double check it. No shims needed for the tilt. just the nod and the Z axis alignment.

I will say this, I would never measure off the plate. I stack 123 blocks on the plate and measure them. I use an indicator holder similar to this thats a little longer:

Amazon.com

That way I can indicate on blocks that are 16 inches apart. That sounds like Im nuking it, but really it makes it much easier to gently tap it into position and when youre done, youve got a very good tram.

1 Like

I have a granite slab I think 9x12 and the tool I am using is a 6” SST tram that is supposed to make it easier. Hopefully with your description, which is a million times better than the video I watched, I can get this last step done

1 Like