No. Not normal.

Looks like wet air issues.

How long were those used? With what’s setting?

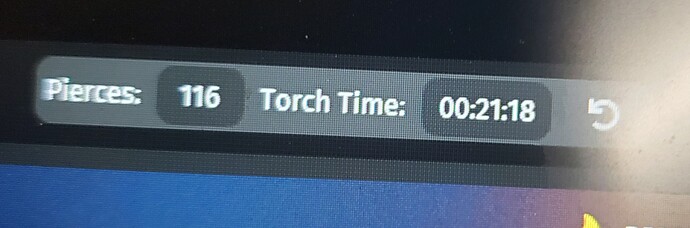

I see the 21minutes at 116 Pierces ( just one program?) 55amps and 0.06 cut height.

Pierce delay?

Pierce height?

What material?

What size nozzle are you using in that photo?

As TinWisperer has said that is definitely not normal.

You need to get your air cleaned and dried up.

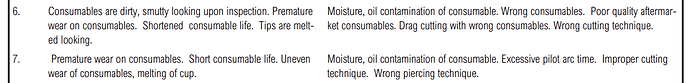

Yes that is one program… ive ran that sdame program probably 15 times already. and im changing the consumables basically once per run. i run them untill the arc drops out (which i dont want to do but im blowing through the consumables so)

material is .250 cold rolled steel.

nozzle is 60 amp which i think is 1 or 1.1mm

shielded cup

pierce height is .15 but the nozzle is retracted into the shielded cup

delay is .7

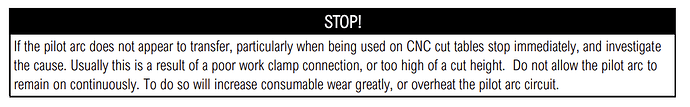

You got an air issue. Wet and maybe dirty to.

That looks really bad. Do you have an inline oiler somewhere in your air system? If you are running shielded consumables, you have to subtract the distance that the tip is recessed from the pierce and cut heights. If it is recessed .030", you should deduct that number from your pierce and cut heights.

This must be specific to that kind of torch?

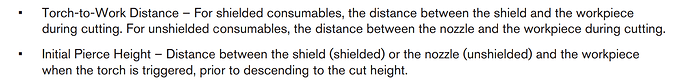

This is how hypertherm treats the shielded unshielded scenario.

Hypertherm wants you to take the cut height from The Shield if using shielded components.

Or take the cut height from the nozzle if you’re using unshielded components.

And these are usually the same height .06

I have a Jim colt post saved where he says the cut height is standardized across shielded vs unshielded, no compensation necessary as the height listed is for the lowest part of the torch. I’ll have to find that again. Do you have a reference for where it says to account for the shield? The shielded consumables cut chart says .06.

Reply meant for @ds690 @TinWhisperer and I are on the same page.

I’m just going by what George said about using shielded consumables.

The plasma arc originates at the electrode and we generally measure the arc length from where it exits the tip. If that point is .030" up inside the shield, it makes sense to me to account for it.

Hypertherm certainly knows what they are doing, so I can’t argue with that. It just doesn’t make sense to me.

Yeah George knows the specs for what he sells for sure. I’m curious to hear what the OPs air setup is. For how bad it looks it’s like he’s running the plasma off diesel exhaust with mud injection.

No offense OP, just being funny. We’ve all had air issues.

im actually laughing right now… i honestly havent put much into air quality and i know its pretty big.

i have the separator/regulator that came with the machine and a separator /regulator on the compressor. doesnt have any oiling or anything like that. i also have an ingersol rand dryer that is currently not functioning (freebie) plumbed in but again not functioning.

im looking to get the motorguard filter some desiccant and a copper cooler setup but i dont have any wall space to mount it which sucks because i already have all the material to make it from jobsites

Have you ever drained your air compressor tank? Should crack drain valve for a few seconds at least once a day ,see how much water is in tank.

yes i drain the tank manually most days… i also have a popoff type drain that cycle each time the compressor cycles.

How / why did you end up with a iptm60 for your 82i ? Why not a iptm80?

I always found it odd that in the everlast 62I, 82I, 102I manual they choose to skip listing the iptm60 torch.

Maybe a pilot arc issue as well as water issue?

60amp is the top range for the 1.1mm (50-60A) Tip (nozzle)

Please let us know about the progress with your air system

A lot of people like to use the PTM 60 torch on the 82i because they can get finer cutting tips 20,30 and 40 amp. The PTM 80 consumables start at 50 amp and that don’t work that well on 20 gauge metal cutting signs.

Note: Don’t get confused here. Tecmo makes the PT torch’s. Innotec makes the IPT torchs. But there is also the Chinese copys calling their torch’s PT and IPT.

I did ![]()

I definetly will… im in the process of ordering parts for an aftetcooler and building a copper line cooler as well from spare parts I have laying around

If you don’t have wall space you can’t mount it around or directly to the compressor itself if you have a standing tank to save room

I Built it in the staggered layout I talked about in another post. So I’ve added IR moisture seperator the copper line cooler an IR filter, a motor guard filter and I just got the aftercooler but haven’t plumbed it yet nor have I gotten the fittings I will need.

So the setup goes IR water trap>copper line cooler>IR filter>line set across the shop>harbor freight regulator and water trap. Then the motor guard filter and another water seperator that is attached the plasma table only