I have my refrigerated dryer above my compressor and my Motorguard filter above that. When the air leaves the tank it goes into a U shaped 20 foot of black pipe with a drain at the bottom then to the dryer then to the Motorguard. And on to the plasma which has a particulate and desiccant filter. The Motorguard filter cartridge is always dry and looks new.

So you use the motor guard on everything in the shop? It last a long time?

Yes it’s feeding everything. I have a Skatblast cabinet that needs dry air too and air nailers benefit also.

It lasts a long time if your air is dry.

Motor Guard is an air filter, not a dryer.

Added all this crap literally no change… anyone have any ideas?

Where are you getting your consumables from?

Is there a chance you go to batch of consumables where the hafnium emitter it’s not properly seated in the electrode so it cannot dissipate heat the copper like it’s supposed to?

Or is your pilot arc never turning off?

The damage to the nozzle is from the electrode expulsion.

What is the air pressure at the torch? Looks like you need to replace all the parts on end of torch, looks to have overheated and destroyed retainer cap and probably the swirl ring as well.

What thickness is material you cut and the machine settings?

Took the words out of my mouth, I would install a gauge here and then set up a camera to watch it while you make your cuts.

Definitely a lot of things going on with the looks of pics…

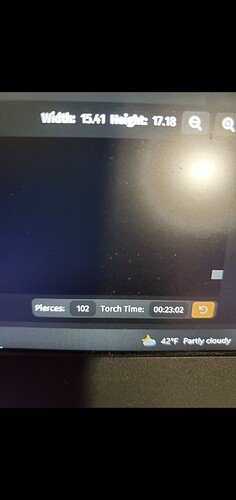

Bought consumables from George’s plasma a few different rounds. Air pressure when the torch is running is 70 psi (the machine has a pressure guage on the front hence the lack of an analog guage on the regulator) running 60 amp consumables at 55 amps. .25 cold rolled mild steel around 40-45 ipm (cut as fast as I can get smooth cuts straight through)

I’ll upload pics of the other parts when I get back to the house.

Do you have work clamp directly clamped to your material that you are cutting?

How would I know if the pilot arc isn’t turning off? I run the everlast 82i on auto restart mode. I see the amps go from 25-55 a few times during the cut but it’s usually only during the plunge other then that it typically stays at the 55 amps

Yes work clamped directly to the material being cut.

That last electrode was the worst one I’ve had. I’ll post pictures of all the sets of consumables I’ve pulled off the last runs

Plasma cutter should be set in CNC and tip saver mode.