Hello, I have searched for this topic and find amazing information using fusion but i dont see help regarding inkscape and sheetcam. I am making a 8ftx8ft sign. i believe the way to approach this is to break the sign into two halves then cut each of those halves in three /indexed moves at a time. i am about to install the elevated stanchions on my table and the limit switches. I have never actually done an index cut. i also am going to install permanent straight edge running parrallel with the y axis full length of the table and runing 18 or 24 inches in the x axis for insuring squareness of my sheets. if anyone has any suggestions i would greatly appreciate pointers and instructions for breaking the design into individual cuttable files and any suggested best practices for getting this design done. the black will be the cut sign…the colored will be backlit acrylic.

@MechanicJon i have watched that video…seems quite obtuse of a process to me, i believe it did not even quite work out in the video. there is actually a good write up here for doing it in fusion…i kinda have grown to hate fusion and would like to work out a good process for achieving good indexing utilizing inkscape and sheetcam. fusion seems to have issue with single line geometry, something sheet cam doesnt blink at. i believe that longterm wise…there will be lots of single line geometry in index cutting so rather than deal with fusion…i would prefer to get a system worked out using sheet cam…my main issue is knowing how to break a full drawing up into separate segments either in sheet cam or inkscape. Thank you for your suggestion though.

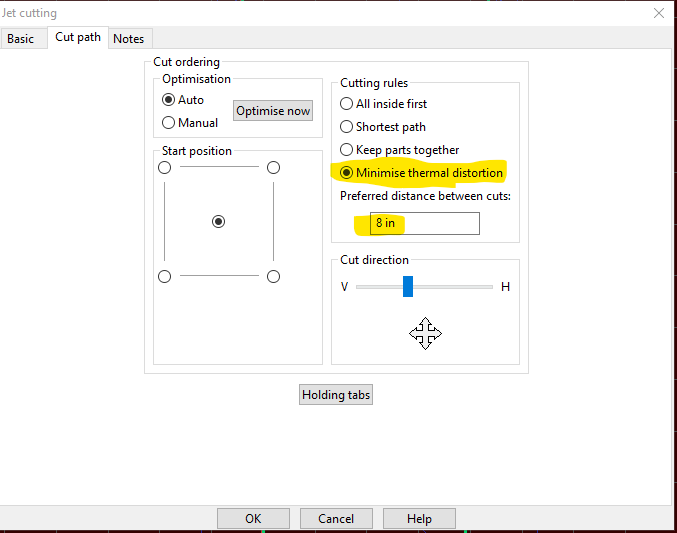

I use the free 2D program Librecad download cut the design into sections that fit the table. Then save each individual part as its own DXF file. (xxx1, xxx2 xxx3 etc…) Then open each individual file in sheetcam do the post processing. Then to table. A guide on one side of table is a must and mark your zero x,y corner. When moving to the 2nd cut I do a dry run torch off to check alignment pausing it where the first and second cut lines intersect. Something you want to keep in mind is expansion of metal. Especially on thick material. When doing an index cut I’ll add a pause at the end of each cut to let metal cool if there’s a lot of cutting done. I also will spread the cutting out to lower thermel distortion.

I don’t know of a way to do it in sheetcam alone.

@MechanicJon thank you…that solidifies my plan…now i just need to determine what progam i will break it up with…The thermal distortion tips is exceptionally helpful…i would not have considered that.

If you decide to use Librecad there’s good tutorials on YouTube or I can answer any questions.