Yes indeed, @Bigdaddy2166. This is the first time I’ve ever tried to push it, and I’m actually surprised how consistent it is. Each 4’x3’ sheet of my project had 550 pierces, so I have to stop in the middle and do a changeout twice. What kind of life are you getting out of yours? I’ve heard people say 500, and even a few claims of 750 for IPT60 consumables, but based on what I’m seeing I shouldn’t push past 250…

I have a similar air setup to yours and I was getting around 300 pierces from my PTM 60 electrodes.

I got over 1500 from my first set of Hypertherm consumables and I only changed them because I had a project with a lot of pierces. I’m still on the second set of consumables at over 800.

I cut Stainless steel a majority of the time. I change mine whenever I load a $600 sheet on that table.

Yes, I know it’s a waste till I screw up that SS for a 15-dollar insurance policy.

For some reason your still getting moisture in your air. Also you need to up the post flow to 30 seconds as those consumables are getting way to hot mainly the electrode. The threads should never be that discolored. Are you snugging the electrode up? Check your swirl ring and make sure it is not burnt or cracked and the retaining cup has 6 holes in it make sure they are open and not plugged up.

Thanks @mechanic416 . All I can really speak to is that the electrode is snug, and the swirl ring is in good shape and installed correctly. I’ll up the post flow, and maybe I should add some pauses in the G-code, because even at 10 secods the post flow never really turns off. I’ll check the retaining cap, too. And maybe I should recharge my desiccant just ahead of my next big project, just to give it a better shot at keeping things dry.

What kind of life should I expect from these consumables under good conditions?

What size is your desiccant dryer? I was using a smaller size one from HF. The beads didn’t change color very fast but I was still getting that black swirl on my electrode and wasn’t getting as much life out of my consumables. I live in an semi-arid steppe… so not as dry as you, but close. I switched to a quart size and have gotten better results. My theory is the chamber wasn’t big enough and the flow wasn’t getting contact with the desiccant… total guess… but if you are using a smaller one try a quart sized one. I got one off Amazon… I think it was true flate brand… $125 or something like that. Only thing about the one I got is that the beads in the sight glass are loaded separate and only connected by a small orifice.

The Virginia City sign looks awesome!!

Thanks Erik @72Pony. I’ve got a quart-sized dryer on there currently. And Motorguard makes good stuff, so I’m not really sure why I’m getting the moisture that I am. I cut for four straight hours for this project, which is far and away the hardest I’ve worked any of my setup. The consumables pictured were shown in the order of their use, so I’m not sure if anything can be garnered by that information. I ran the first two sets to failure because I was hoping they’d go to 500 pierces on thin metal at only 45 amps.

The only other explanation that I can offer is that I was getting a lot of splashing and standing water on the workpiece. And there was one spot on each of my 10 signs where they just warp a lot during the cut, as a fault of the design, so I think I could have had a little light tip contact on a few of the pierces. It would have been minimal, though, as I was using a dialed in nominal voltage setting, so I know that within 1/4” of the pierce, my cut height was stabilizing via the THC.

Anyway, thank you! The sign is a scaled down version of the sign you see as you enter Virginia City. I was able to sell 10 of these to locals as a pre-order type of deal, and between babysitting the cut and finishing the signs, I only had about an hour in each one. Not counting design time, of course. Still, I had a lot more interest than that, so I’ll probably do another run soon.

so @CrazyCasey I run a Everlast 62i…and have been for 4 years…and had a 50s fbefore that…and I have never had electrodes look like that bad…

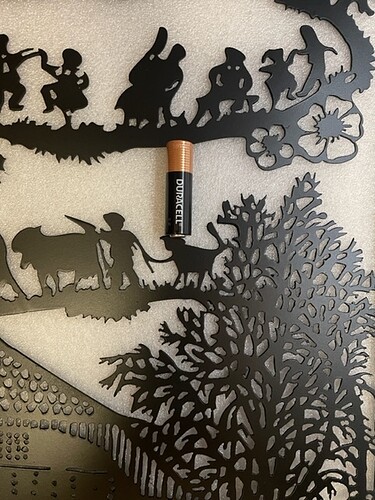

here is a picture of a set I pulled off a while back…16 gauge…1 hour on the table cutting with 1880 pierces…

I just finished cutting 3/8" steel…and diid around 30 minutes of cutting and around 40 pierces and they look like new…

I also run post flow for 45 seconds minimum…air is cheap really…

I get mine from Everlast themselves…

Is that a typo? Can you explain? I can’t wrap my head around 1,880 pierces in an hour of cut time? That’s more than 1 pierce every 2 seconds, which is about twice as fast as the IHS sequence itself.

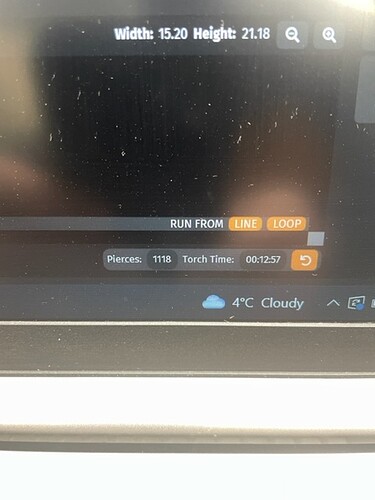

The time in fire control is actual torch on time.

Ok, so it’s 2 seconds of cut time per pierce. 1,880 pierces out of IPT60 consumables is still pretty unheard of, I think. It makes me wonder what I’m doing so wrong to get 1/8 the life out of arguably better made consumables* (Tecmo vs Chinese).

*To further qualify that statement Mark @ Everlast told me to throw their consumables away; said they were far inferior to genuine Tecmo. ![]()

Damn, Glen! That’s impressive. Are those “pierces” or pecks? I did get to 700-something on a set that ~550 of which were pecks, back when I had the Primeweld Cut 60 (same air setup). And those consumables weren’t toast, either, that’s just where I changed them out…

*Edit: I take it back. I just saw your post of the cut. Fantastic! I can’t even wrap my head around what you did there…

So, I guess it must all come down to air. At ~13 minutes of torch time, your 45 second post flow is completely irrelevant. Mine at 10 seconds was still barely turning off on my design, because it similarly had a lot of small detail.

Am I reading that right… 1118 pierces in 13 min. Thats crazy! Thats 1.4 seconds of cut time per pierce. Was that from that sign you posted a while back?

13minutes of torch on time…torch cutting time…

the time from start to finish on the table was almost 1 hour…

here is a picture of the details and size…the battery is a double A (AA)

it may look distorted but it is the way the artist drew it for a greeting card…

so I am concerned abiout this comment…

are you saying you only run post flow for 10 seconds?..

your joking right?..?

at 10 seconds you are “cooking” the internal components and warping the electrode…this will result in premature electrode failure…

So, honestly, nobody ever told me different (prior to this thread), and being completely new to plasma cutting last year, I just didn’t know that 25-45 seconds was the norm, as 10 seconds is the default on the machine.

That said, your one hour project with 13 minutes of torch on time, results in 1118 pierces in ~47 minutes. So, you’re piercing every 2.5 seconds, which means that your actual post flow is effectively no more than 2.5 seconds average (some longer some shorter), right!?

The only time it would get the full 45 seconds of post flow is at the end of a cut, or during any pauses in the program.

Unless I’m fundamentally misunderstanding something, in which case I would love it if somebody explained that to me…

And again, you ARE the master. That cut is a work of art! I definitely don’t mean to second-guess your advice, and will 100% make the change on my own machine in search of that quality…I’m just saying the math doesn’t add up.

Yeah I got that. That’s a crazy ratio. It’s all that small detail in that sign. That’s why I asked if that was all on that sign. I remembered when you posted it initially. Really awesome work!

Talk about the pucker factor. 1100 pierces on a 3x4 piece of steel would have me chain smoking. Well more than normal ![]()

You are right… the only time you get the full post flow is at the end… but the air is always on/cooling while cutting… and continues to cool for 45 sec afterward.

I use 30… just cause that was what I read as a minimum.