I was tasked by my daughter to make this door bell decorative plate that was about 3.6 inches x 5.7 inches.

I had to sacrifice quite a lot of detail and got to this:

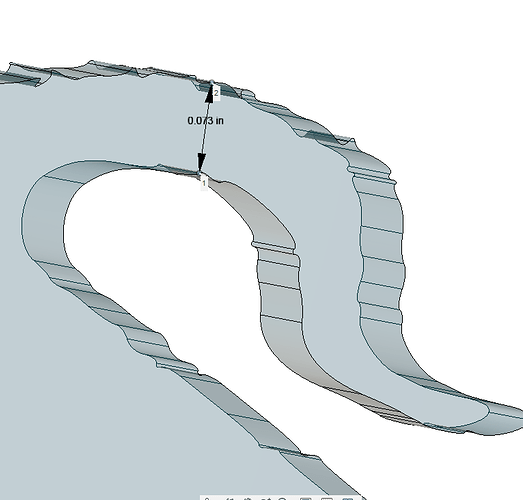

But you can see with the dimension of the tongue, I was still going to have trouble:

Normally I cut everything with 45 amps. This was 16 gauge so that would be at 249 ipm which would be a kerf width of about 0.053 inches. Every time I tried this, I would lose lots of detail. Another member had written about experimenting with less amperage on 16 gauge (@Cletus). He wrote that by decreasing to 30 amps and running at 150 ipm, the kerf was drastically reduced. Even though we have different cutters, I tried his numbers and this was the result:

So as ToolBoy suggested, decreasing your amps could be another possible gateway to success.

I did not have any Fine-cut consumables at the time. That is another option if they are available for your cutter.

If you want to check out some crazy detail: