I use the wide mouth multi-coat nozzle and they recommend using it at 100kv. I don’t get any fish eye, and I don’t think I get back ionization, my coverage seems pretty clean. I’ll put a video of the static noise next time I shoot. I do have an earth ground connected to my part hanging rod by 6AWG bare copper wire and I’m running the alligator clamp from the gun to the hanging rod. I haven’t gotten zapped by it but it’s definitely singing.

I saw that he tried that, wondering why so high? I hardly ever go over 40

Take your barrel off and clean the electrode. May help I also hooked up the Rinse line can’t say yeah or nah yet. It is supposed to keep the electrode clean

I buy the the 45% and dilute it to 5-6%

I just did a color change yesterday and blew the hell out of the nozzle, should I be physically wiping it when I clean it up?

That is what the recommend most I see use 100 kv. Then turn down the micro amps which isn’t a option on this setup.

Yes and every now and then I clean mine with rubbing alcohol. Make sure it’s good and dry before using. Might do more than bite you

Do you take it off and blow it out? There’s a black ring that can come loose from the tip that can accumulate powder

I use that same tip. I was using the flat tip. I’ve never used it at 100KV. I think they like to sell that tip since it uses so much powder.

I did yeah, the collar came off the nozzle too so I blew that out as well. That black ring is only held on on one side. Actually there are two black rings, one attached to the gun on one side and the other is part of the nozzle. The whole thing is kind of sketchy but it works great. I was very thorough in the cleaning out. Anxiously awaiting the arrival of the new hoppers and latex tubes I bought for each one, that will make cleanouts a bit less frequent.

I use the standard nozzle with the wide mouth multi coat tip.

Just cut the first sign maskings on the vinyl plotter, I’ll try them out tomorrow. I’m actually going to be doing three colors on that sign, but I have to wait for the third color to be delivered. The vinyl mask is 23" wide which is well past the recommended cutting size for the roll I was using. I’m going to have to order a 30" roll I think just to make it easier to setup and go without all the tiny adjustments trying to fit the blade on the vinyl “just so”. Man the more I think about it the more I’m realizing I have entirely too much video to edit…still.

I am watching this thread very closely. I am very interested in the process of masking and multi coloured powder coating.

Just cook part until powder flows the longer you cook it the harder the vinyl is to pull. I used to do that on tumblers often.

How cool can I let the part get while pulling the vinyl before it ruins the cure? Can I put it back in the oven say 15 minutes later and finish the cure?

Same here…lol

Room temp. I do some two stage colors you cook or partial cook cool then second stage . Depend on color. To cure most paint it’s 400 for 10. Some paints are different

If you pull vinyl hot comes off easier but you have a chance of pulling paint you don’t want to .

Practice before you do a real job

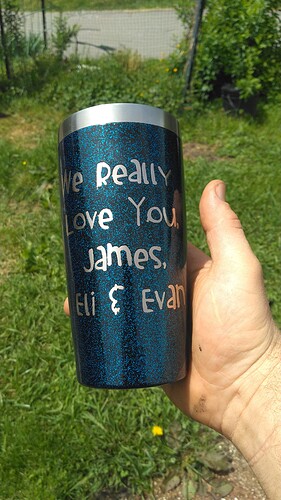

Here is a cup I did for my brother and sister-in-law. They have a deaf child

So you only partially cure the base layer before you put on the vinyl? I was thinking cure base layer, then put on vinyl then partial then remove vinyl then finish 2nd layer cure. I already cured the base layer for the part that needs the vinyl so hopefully it still works.

Off topic I talked to Columbia Coatings this morning on the phone and they said if you run 100k it’s normal to hear the static, so that’s good news.

Just experiment to see what works best for you if you fully cure with vinyl still on you can get edge pull that can distort paint edge