I have the Crossfire Pro and the Everlast 62i. After 2 months of minutes here and there, I am finally set up. New Craftsman compressor 60gal…yep…shes pretty! I initially used the CNC connection and knew nothing about hooking up pins 1 and 2…but eventually,using raw voltage and all connections complete. I ran the test for voltage and got hung up at Live Voltage. So the 1st test was fine…hit torch then hit Arc. machine making puffing noises…I wait…hit it again and success …same for 3rd time…the test was successful and i am within parameters. But that is all that happens…it fires then after a couple of seconds it stops. I should say that I am new to this…but my brother told me when I was a little girtl…if you can see it you can do it. SO here I am. i have read until my eyes are blurry. And not understanding some of what I am reading isnt helpful. So I need some guidance please. if I go to do a straight cut or the test…my cutter fires and then stops. the program continues but no fire. i feel it is probably something simple.

Ok… A few questions?

Make sure that the buttons on the plasma cutter are set as follows. First button set to CNC.

Second button set to auto restart. Third make sure you have at LEAST 75 psi on the gauge on the front of the machine. Not 60, not 65 not anything but 70~75 psi.

Please send us a picture of your torch mounted on the table. Ensure that the work clamp is on the metal you are cutting. Very important…

Please check all these things and report back.

i knew you would be one to help me… i will fix the torch… i have two…one handheld and the cnc…but neither look like that…ill take a picture and try with those settings…i think im already there but ill double check

can you show me your mount…mine is very low…

I’m home, but turn the Langmuir bracket upside down if you need to. Maybe some of our rocket scientists will send a picture of a torch mounted correctly. Make sure that the electrode in that video can be pushed up with your finger and snaps back down.

ok…i did have to turn the bracket over…but my screws arent long enough to open it up enough to fit the body of the torch

Send us a picture of the machine torch.

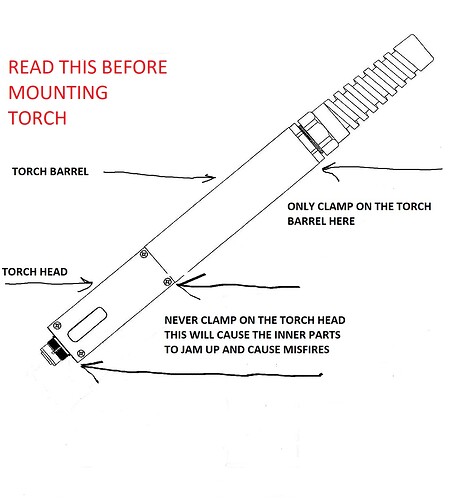

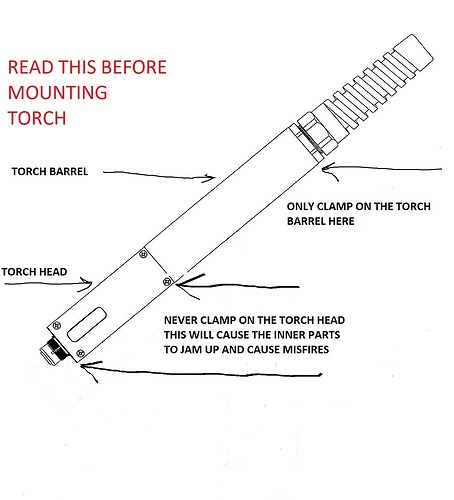

Turn the LS bracket over and bolt the torch above the area in the picture

that says not to.

And if it does work please put water in that pan before you try and cut anything.

im just holding it there

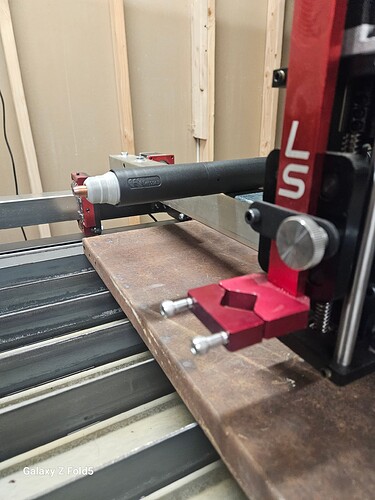

You need longer bolts. Something doesn’t look correct on that torch holder.

yes…my pan was leaking… so much has gone out…i have repaired and will add…thank you

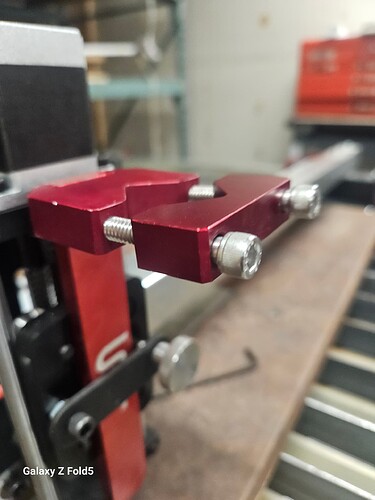

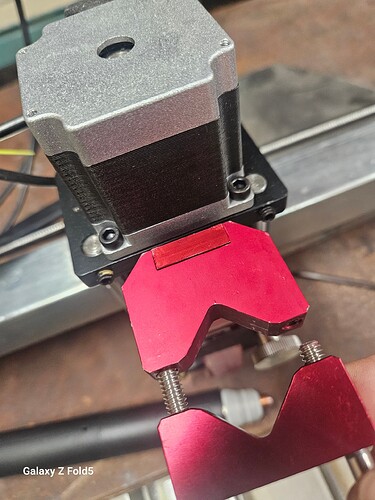

This is a torch setup from one of our forum members. This is mounted correctly

The OP @Jet , welcome to The forum by the way.

Needs to buy the machine torch holder for his machine torch.

The hand torch Holder will not work so good.

The hand torch holder clamps to the consumables. the machine torch holder clamps to the barrel of the torch.

-

Don’t use the thumbscrew with the machine torch

-

Use a machine torch mount for a machine torch

so…this is the only mount i received…here is what I did…longer bolts…before i saw how different the mounts are…will this work…or is it unacceptable

For now. Let’s see if it works. ![]() Water, water

Water, water

What is it that you are trying to cut? Hopefully, it is not 1/2 A36 steel.

now no arc…ugh

Buttons correct? Air pressure? Work clamp on metal? If you take off the torch cap can you push up on the electrode? Like the video.

Please send pictures of the VMI box wiring.

We will get this. No worries