Your trying to use a hand torch mount on a CNC torch. Its not going to work very well till you get a CNC torch mount.

Just focus on what @Bigdaddy2166 is suggesting.

These tables are extremely easy to diagnose, but you must follow specific steps to get to the root cause.

The plasma cutter is independent from that of the table, and has specific requirements just for it to work in general. Once you understand this, it’s easier to start figuring out what the issue is.

ok…yes…i can depress the piece inside the torc. yes my clamp is to t he work. I believe we can solve…i have read many threads where the solution comes…i decided to go raw voltage because of these threads. I appreciate everybodys time to assist. here are the photos you requested. i have a question about the air check. i press it and it goes down to 45…then back up…is that correct?

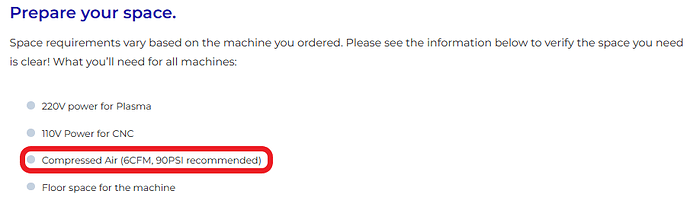

If your air pressure is dropping to 45 then that’s your problem. It should be sustaining much higher like 70. What’s your regulator set at from the compressor?

That’s your problem. It should only fall 5 to 8 psi.

By the way. I was mistaken that button in the middle should be in the Tip saver mode.

Jet has reached the 20-response limit. We will continue this later, I guess.

Tell us your air line size and what all you have from the compressor to the plasma.

Jet sent me a message that the 20 message limit had been reached.

Just when we had a responsive person we were all excited to help….

I can’t think of a time someone hit that limit. Usually we are just twiddling our thumbs.

I guess it keeps people like me from carrying on about limit switches and such.

I believe that it will work out for Jet tomorrow.

Jet, I assume you can still read the responses here…

You need to get the CNC torch mount on order. You will not be able to hold the CNC torch rigidly enough to keep the arc length constant (or get any kind of consistent bevel on your work) due to vibrational / acceleration induced pivoting.

I might recommend biting the bullet and getting the Beck’s Amory Laser Mount while you’re needing it. The lasers will help you in the long run with material alignment. Not pertinent to this discussion, but kill 2 birds while you can.

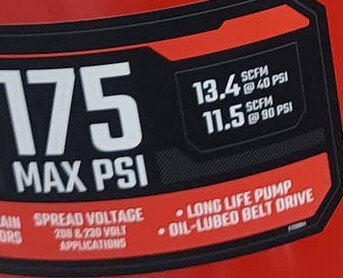

Since you have an “off the shelf” craftsman compressor, which model is it, specifically? Have you added anything in line between it and the Everlast?

from my messages

i am strugging to keep air pressure constant or not dropping so much.mill describe my setup…60 gallon craftsman…maintains160psi while taking a nap…then a pressure regulator…everlast said necessary…then air dryer.then regulator at th cutter…then on in to the cutter ![]()

Using 3/8 in hose…no leaks…probably wont be able to message back***

Maybe a cutter issue? I don’t see that air line or filters causing that much of a drop. We would need to know what each regulator is set to?

Can @Langmuir-Johnny or @ChelanJim bump up their trust level?

Run the air pressure as high as you can to the last reg. Use the last reg to get it to the 75 psi you need at the cutter. As high as you can is a few psi less than the max on either the compressor or your filter whichever is lower.

You could add a supplemental air storage closer to the cutter.

Something like this:

https://a.co/d/ddruD7D

I find it hard to believe that a 220v Craftsman with 60 gallon tank rated for 13cfm is the issue.

I’d be suspect of a bad regulator (or one set too low) or air leaking somewhere in between. Or even inside the plasma cutter.

I say this having run a +30 year old 110v Craftsman with a 20 gallon tank rated only for 7cfm, for over a year without issue (not ideal I know).

(For the OP to read)

I think this is likely the culprit. maybe try bypassing each one individulaly starting with the one off the tank, to determine which one (if any) is faulty.

My guess is it is the one on the cutter, I seem to recall someone having an issue with a new Everlast cutter some months back that had a bad regulator from the factory. He seemed to suggest that Everlast knew they had a bad batch and was quick to send a replacement.

Edit, this is the one I was thinking of… it was an air solenoid not the regulator.

Try bypassing the regulators first… then if you can’t resolve it call Everlast and have them help you trouble shoot the problem.

I agree. I seem to think that several were faulty from Everlast. I can’t believe that that 60 gal air compressor can’t keep up with a plasma torch.

As said it could be a Everlast faulty regulator. I also see a few splices in the air lines. Also could be the regulator at the compressor or the filters. You can have good pressure but not the amount of volume to make it work.