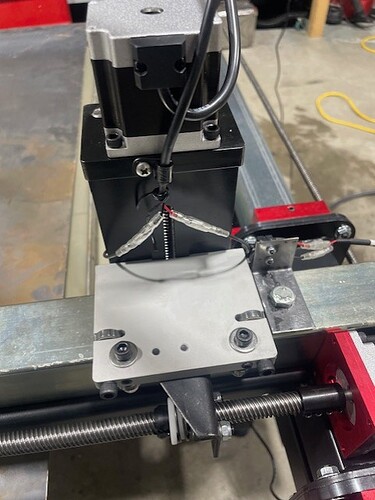

Hi All, I’m a new Crossfire Pro owner and I’ve just finished assembling it(Z-Axis w/ THC & Hypertherm 45a SmartSYNC). I’ve run the break-in program and done a few dry runs of parts made in Fusion360. When I go to make my first cuts, I get an IHS Fail error. The IHS icon at the bottom of FireControl remains green at all times. After a bit of troubleshooting and reading forum posts, I understand that the circuit is remaining open when it should be closed. I’ve ensured that the blade plugs(in the attached picture) are fully inserted and also that the IHS wire is connected to the electronics enclosure. I was wanting to take the blades out in order to ‘short circuit’ them in order to see if the ‘IHS’ will turn grey, however they are in there pretty tight and I’m concerned that if I try to force them apart they may break(maybe i put them in too tight?). The plastic around the blades actually started sliding but the blades themselves seem quite firmly connected. So I slid the plastic and ‘short circuited’ the blades while still attached. Sure enough the IHS icon immediately went grey. The screw that the left hand wire attaches to does seem somewhat loose(i.e. I can rotate the wire fairly freely). The screw that the right hand wire attaches to seems solid. I’m not sure but I believe it’s the screw that the left hand wire attaches to that is the problem. Any suggestions/best practices on how to access that screw in order to tighten this connection? It is somewhat difficult to get to and I imagine I will have to disassemble the z-axis to some extent.

Thanks for any suggestions