Hey ive been placed in charge of the cnc table at work and ive been diving in trying to understand the table as well as fusion 360. My question for now is how often does anyone have to change the lead nut on the z axis rod? Mine seems pretty wobbly and my torch drags at points during cutting. Upon inspection i notice that occasionally the copper plates linked to the lead nut and the plate on the torch carriage seperate for a second. Berrings seem fine so i dont think they are catching and ive cleaned the rods they ride on. Thanks in advance for any answer’s given this round.

Welcome!

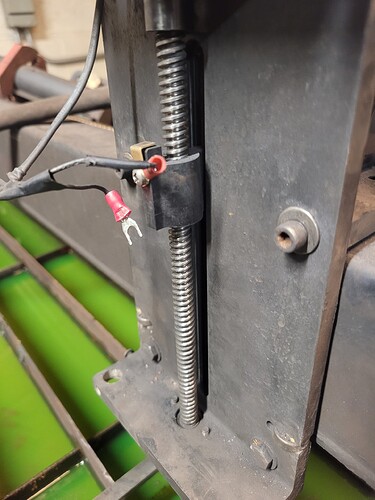

Can you take a picture of this “lead nut” you’re referring to?

Nothing should be loose, and dragging of any sort is not a good thing.

Maybe we can better help to figure out what’s loose and what needs fixing.

This is a quick and dirty video I made for disassembly of our Z axis assembly -

Thank you i will get a picture shortly its that black plastic piece on the lead screw of that z axis assembly video you shared. I also notice from that video my plastic plate that has the ihs connection does not have that spring on the lower portion.

Yes, at least on my machine that nut does have some play. As far as I know it’s always been that way. My machine works, so I’ve never investigated.

If you’re missing springs; ect. and those contact plates are not staying together, that’s a problem.

Yeah i just managed to replace the lead nut on the lead screw i sent a picture of and its tighter then my old one. Also my plate that sits on that lead nut is different then the one in the video the gentlemen shared. I have no connection spot for that spring and there is no spot in the bottom of the lead nut for it to sit in. I lowered my torch so it doesnt have to go that far down the lead screw. My apologies for the scatter brain on here this whole thing is relatively new.

@Learning have you looked through this document ? It shows the disassembly of both the new and older version of the Z carriage.

z-axis disassembly IHS Contact Switch Components Swap Guide.pdf (7.1 MB)

I ve heard of members using a ball point pen spring as a temporary replacement for a missing spring.

Thank you for that document and for the tip on handling the spring issue for now. I just got the ihs wires replaced a month ago and recieved a replacement plate and lead nut i assumed it would be the up to date one but the spring is a feature we havent used in the 9 months of operating this table. Diving in to gather more.

If you still have that z-assembly apart, I highly recommend put some blue thread lock on the machine screws that hold the wires. That will resist them coming loose, as they sometimes do.

What @brownfox you definitely need that spring.

Regarding play, I too experienced it and went as far as getting a new Z axis assembly as well. Come to find out, they all have it but only at the bottom of the Z axis travel.

What remedied that was physically moving the mount down another half inch or so leaving alone that last bit of negative travel unused.