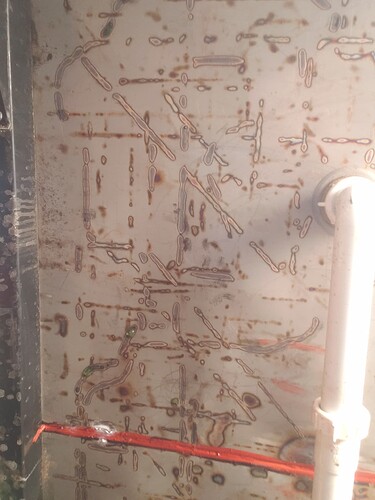

Yeah, Evidently my plasma was working better than usual on the 100 amp setting, combined with I should not have cleaned my pan.

4 pin holes (I am sure they are actual cuts that welded back together or slag sealed from the top).

It did however make some very nice cuts on the 3/8 plate. All lifted right out, and minimal slag, more like a burr, some with nothing.

I think it was the 28 ipm on the tight corners and holes that got me.

Been using it for a couple months now and evidently got lucky.

Oh well. just makes the upcoming mod a little more urgent, like ASAP.

3 Likes

Ope… lol… but hell yeah bud… she’s eatin’!

I’m diggin the drains… I’ll be doing that… and I’ll be watching the pan when I’m eating 3/8" this week hahahhahaa (though I’m not sure the Neverlast 82i will be capable of such awesomeness)

1 Like

Another member here warned me about his 82i blowing a hole in his pan when I was making inquiries.

Keep the water full, like 1/2 from the top, keep a mop handy for the splash, put a sacrificial plate of 16ga in the bottom, or lots and lots of slag - don’t clean your pan.

I wonder if a layer of Lava rock would do the trick…Hmmmm. Would have to literally wash it periodically. Like tumble wash.

1 Like

Yes, @TableSyrup the neverlast 82i can blow a hole in your pan. @Sticks, Heed his warning.

1 Like

It’s almost like there should be a minimum water column spec in the pan for a given current output.

As the “Wizard” (Tin) said “Everything is a variable with plasma cutting.”

(Note: I am trying to get that new moniker to stick! I am pretty sure he is not a bot!)

2 Likes

Height from pan to troch appears to be the winner. 1" lift on my slats got me in the safe zone.

2 Likes

You could also do ceramic tile in the bottom of your pan.

1 Like

I was pondering lava rock.

Another solution is in the works. Updated thread to come

1 Like

I did the same thing. Now I just leave the debris in the pan. When I gets too deep I pick out the bigger pieces and leave the slag.

2 Likes

For that matter, I suppose you could add sand in the bottom of the pan.

1 Like

Given the amount of water and mess that gets splashed around I’m not sure I’d want to add sand to the mix…

2 Likes

Yea, a thick heatsink would be a better option, or more water.

1 Like

Just keep the table full of water. I can cut 3/4 all day without any issues. I do put a 30 x 46 11 ga plate on the bottom that has a hole in it for the drain. Just a precaution not to ruin my $ 600 SS pan

And a note that on occasion, I have tattooed that plate several times.

Obviously, the slow travel speed for the extra-thick stuff is the issue.

Leaving the pan full of trash is something I can’t get my brain to accept. Hell, I clean my pan every day before I go home. Get a large shop vac, drain the water in all your different designed holding tanks, and vacuum up till clean. 10 minutes max.

That is a personal choice.

8 Likes