Hi all, I just got a used Pro table with the THC, super excited. I have a Hypertherm powermax 380 plasma cutter. Does anyone use this machine? have any recommendations on wiring? Images? Thanks all

Yup that’s the one.

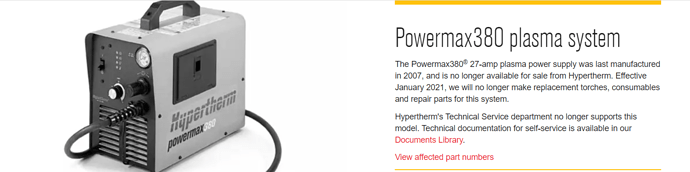

you do realize that they are ni longer supporting or making parts for this…

apparently it is on the Langmuir supported but discontinued page…s I guess it is OK for the table,…

@mechanic416 is our resident guru on plasma cutters…I have tagged him and see if he can shed some light on this for you.

Thx. Yes I know this is an older (just like me) plasma cutter, but it’s the one I have for now. I think I’ve got it worked out but thought I should still check to see if anybody has this setup.

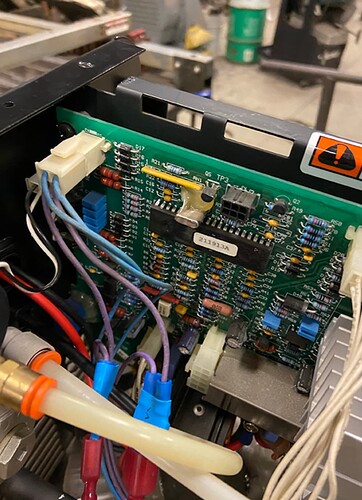

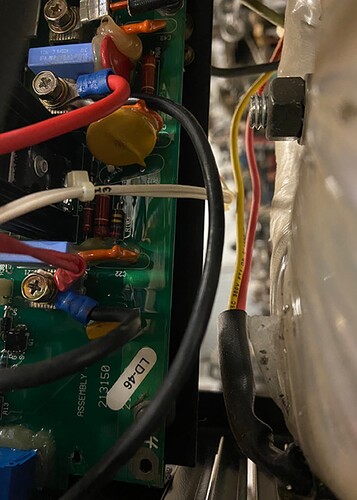

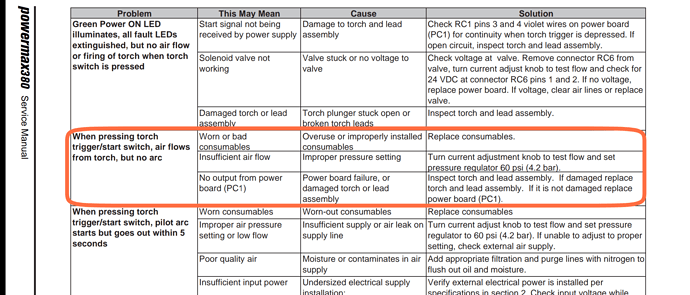

OK friends, I thought I had this right but apparently not. From FireControl I can get the torch to fire (Air only) no arc. Voltage readout doesn’t go past 20. Was running torch on 110. Should I switch to 220? Please advise. Here is how I have wired it. Thanks in advance.

THC.pdf (1.0 MB)

torch control switch.pdf (1.1 MB)

Whether you’re torch is running off 110 or 220 volts that should have no effect on whether that torch relay closes or not.

I thought I would post those pictures so people don’t have to download the PDF

Here is the manual link.

But does the front display of your hypertherm code out any errors during the firing?

No codes. I didn’t think 110 or 220 would make a difference but doesn’t hurt to ask. Thanks for the repost of the images

I would switch it to 220 (I mean the outlet and switch, they should match) just so you can get more power on your machine and cut thicker material.

What is your consumable stack up look like? Good condition overall?

Did the torch manually fire with the trigger?, before the conversation

I’ve got plenty of consumables. The torch did fire before I hooked it up

Where you placing your ground clamp?

What part of the torch you clamping the mount to?

https://www.hypertherm.com/Download?fileId=HYP104631&zip=False

Here’s the service manual

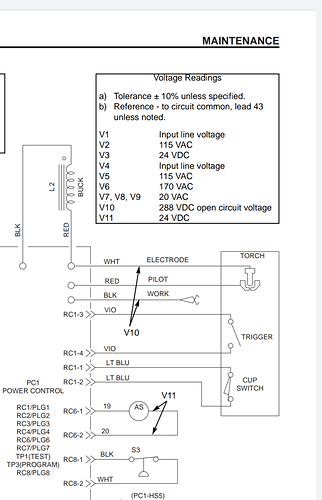

In this picture v10 is where you’d be getting raw voltage from.

That all looks like how I hooked it up. I believe I have the proper work/clamp hook up. I did get an air pressure light but I upped the pressure and it went away. I’ll keep tinkering. Thanks for all the help

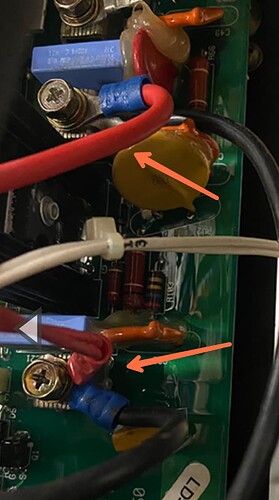

If these are your raw voltage connections Id take a really good look at this verse the diagram.

Are the blue crimped wires from your THC?

Yup the blue ones are mine. I’ll certainly have another look at the diagram

Bam!! You got it. I was tied into the pilot not the torch. Just switched it. Works now. THANK YOU!!

Please do not tell me @TinWhisperer called the material plasma clamp the “ground clamp”…when it is actually the torch that is negative and the clamp is positive…

am i mistaken here…???

It’s still a ground clamp.

Most (all) plasma machines are a constant current electrode negative machines.

So the ground clamp can be positive or negative.

In a lot of welding machines depending on whether you want electronegative or electropositive you’d switch the leads around but it would still be a ground clamp.

Almost got me. Lol

You can have a positive ground.

And it’s ground relative to the machine not ground relative to the overall electrical circuit of the building.

Very true, however, in this case it is NOT a ground. It is a Current Sense cable for the PC current control logic. This is why it should not be grounded, and should be connected to the metal being cut as reliably as possible.

DARN!!!..you is to " S A R M T " for me