I have a Razorweld 45 and thinking of stepping up to a Hypertherm 45 sync. I cut a lot of signs. And wonder if the fine cut tip is much better than the Razorweld ?? And if you have a Sync what do run for all the Parameters ? Kerf width / etc… Thanks Dave

Hi Dave,

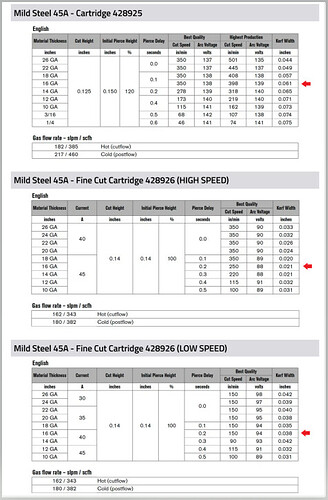

This is the published cut charts for the Hypertherm 45 SYNC machine. I put an arrow at 16 gauge so you can see how you can change the kerf width whether using the normal cartridge or the Fine Cut cartridge.

(Note: More recently, Hypertherm has been giving guidance to suggest better cut quality by decreasing the cut speed slightly with water tables vs downdraft tables. I could not find what the actual percentage decrease. Most of us with Hypertherm start with the chart settings and nudge the settings from there. For the most part, the charts for the 45 XP serve my purposes. I do NOT have the SYNC machine).

Non-sync user here (have been told to stay away from sync) but Hypertherm’s finecut makes a difference against it’s own consumables

Both Hypertherm, one finecut, the other isn’t, both at book settings on 16 gauge.

And another, but with the water level much lower.

20% is what I was given from hypertherm tech support last year, and that seems to fall in line with what I have to massage my cuts from their cut chart to reality.

I made the plunge today, my wallet bleeding, should have a good idea on performance relative to the Razorcut next weekend. My first welder was a Razorweld 3in1 and still use it for stick welding, but find it’s an ok machine. The $$$ replacements I’ve purchased for wire feeding and TIG welding since are day and night difference compared to the Jasic unit.

It’s like trading in your Hugo for a G Wagon Mercedes. Like the Mercedes, the parts are twice or three times as high. I am not sold on the $50 sync consumables just yet.