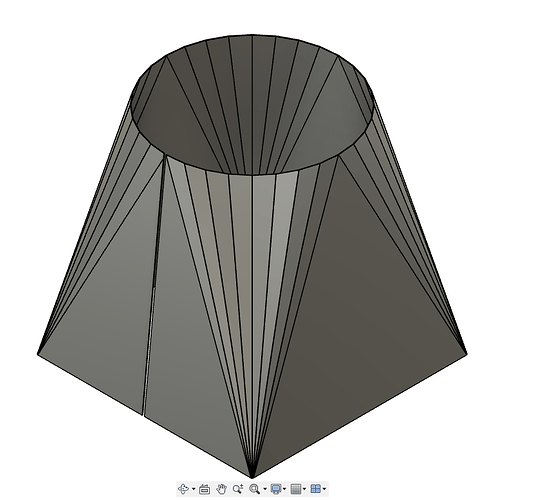

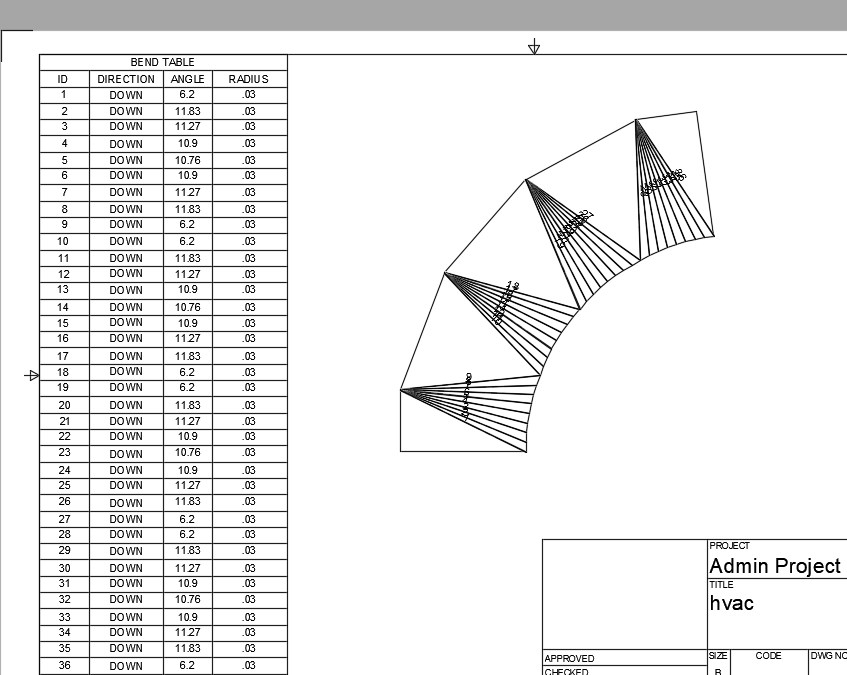

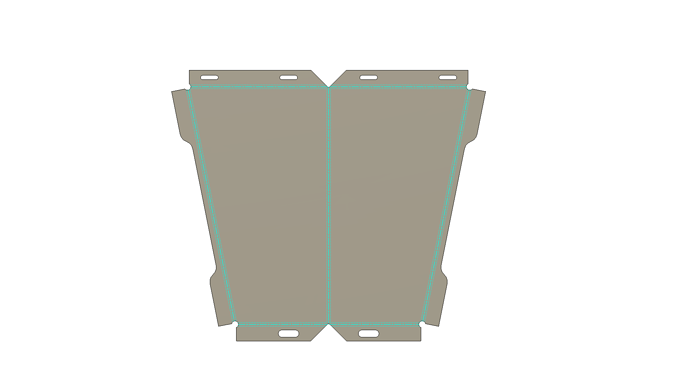

did quick video to give another way but Tin is HVAC guy and I just play around in fusion. I have never cut or bent this stuff. Some really cool things in fusion. Of course, I would need to add tabs or way to join like Tin did on flat pattern.

@DonP looks good, quick and to the point of sheet metal flange/loft tool.

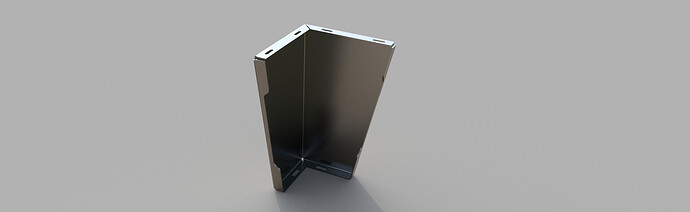

The reason I split it in half so it could be fabricated on leaf brake instead of needing a mag or square to round brake.

With thin enough metal you could do it in one piece in the leave brake too.

Speaking about a square to round brake I’d love to build one, here is a example of one.

Thanks for the understanding why and details you talked about in your video. I don’t play in this space very often. I could reduce the number of bends as you had shown in your video. I’ll never bend something like this, but I must watch a video now on that bender. I’m always learning in this fun hobby!

The one thing I was debating on making in this space was a in wall dryer vent so you could slide the dryer all the way to the wall and attach your duct up. One that goes between the studs. I seen this a month ago but haven’t got around to it.

Something along these lines.

We fab and rough in a all galvanized version of those dryer boxes in every new house we do. Very nice to have those few extra inches in the laundry room. Normally we also request the every wall with any mechanical systems to be 2x6 framed.

Thanks for taking the time to make the video! Always good to see multiple perspectives!

Your audio in this one was much better so whatever you did different keep it up… Or maybe my hearing is getting better… but my wife would disagree. ![]()

Good ideas… I am going to be building in the spring… definitely going to implement these… I hate the space behind the dryer… hate seems like a strong word to use… but it really isn’t strong enough here. ![]()

Made a another set of 10 " legs for a Crawl space furnace install.

I forgot to take after pictures but I’ll be back this week.

here is a link to the other time I made legs like these

I also plan on making some unnecessarily complicated fittings for this since now have a XR and can fit a Full sheet on the table.

That is a pretty big crawlspace but what a neck/back breaker! Just tall enough to make you think you can stand up. Ugh!

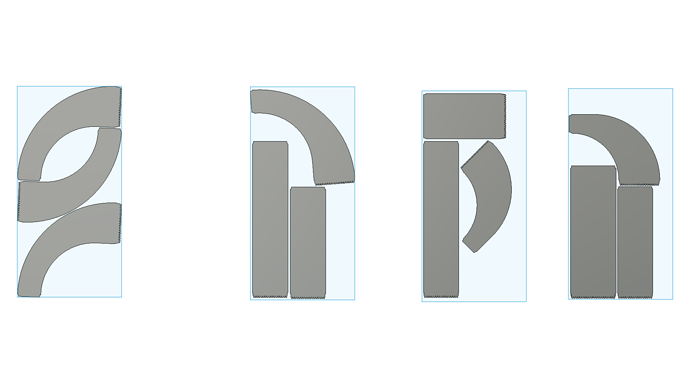

Here are 4 nests that will be cut and assembled at some point today.

12 pieces; the cheeks, throats and heels for 3 fittings

26ga galvanized. (.021"+/-)

Will be running

Hypertherm fine cut consumables @ 25amps

325ipm

.45 cut height

.8 pierce height

0second pierce delay.

fit together and ready to set down the Pittsburg seam

Cutting galvi sure makes some nasty red brown smoke

We did install these larger elbow takeoff combination fittings and the SS legs.

I am going to install a system in my own home soon. Maybe we’ll do a topic going into all the design and install aspects of the project.

Will be a zoned dual fuel system. ( Nat gas and heat pump )

That is a thing of beauty! So nice to see guys in the trades at the top of their game

One question, do the elbows support the I guess you call it the plenum? Or is that the return?

Thanks

it is hard to see but the plenum is supported by a pair of drive cleat hangers. You can see it between the 2 elbows . Once ductwork is attached to the elbows that duct with also be supported.

ok now I see them. You can tell I’m not a HVAC guy!

If you were TW would steal your manuals! Well, maybe not steal… more like he would get them to sublimate… That’s within his magical powers. ![]()

Uh, but you DIDN’T HEAR IT FROM ME!!! ![]()

![]()

![]()

![]()

Cut out a sheet of 4x10 boot offsets. Nice to get the XR involved in the HVAC. It was the reason I upgraded from the PRO.

I will follow up with some assembly pics once that’s done.

I’m very overcommitted with my work schedule currently so I’m skating around everywhere.

This is 26 gauge galvanized so I use the same setting I shared above.

I’ve cut lots of galvanized sheets, but have never got them to come out clean without that dirty Brown gunk all over. Do you have a secret of why your sheet looks so clean after cutting. I’ve also found the only thing that takes the gunk off is dip a rag in your tank water and if comes right off.

Don’t feel bad. Tin has some magical force that envelopes him.

But he does lots of testing until he finally hits on perfection. He is the Martha Stewart of plasma cutting.

I’ll bet the underside is pretty nasty.

The drawback of a water table.

Most HVAC cutting is done on a dry table but without that option we cut on a water table. A single wipe with a towel after cutting removes the brown/red smoke stain and water splash.

The top side always looks good and the underside I wipe with a towel as i am removing the parts. No secrets. I keep the water table fully topped up and cut with the settings above.

If you let the smokey film dry then it is a pain to remove.

Highly Questionable…