Yeah the OP added that at the exit of the cooler.

I see that now…thanks

Ok seriously. This should not be so complicated, but I’m struggling to figure out what to buy for this. Mainly because I can’t figure out what to search for. I’ve taken everything apart and measured everything, but I can’t find the right configuration.

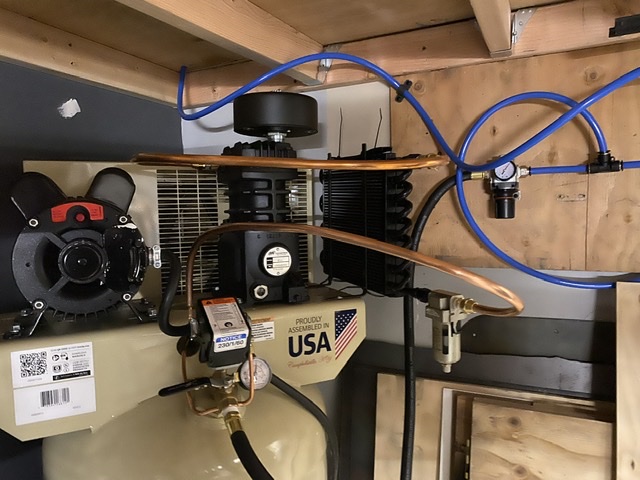

My Compressor pump has 3/8 NPT female outlet which from the factory has a 3/4 threaded female double flare fitting. That side is easy, Just use a compression fitting to 3/8 male NPT.

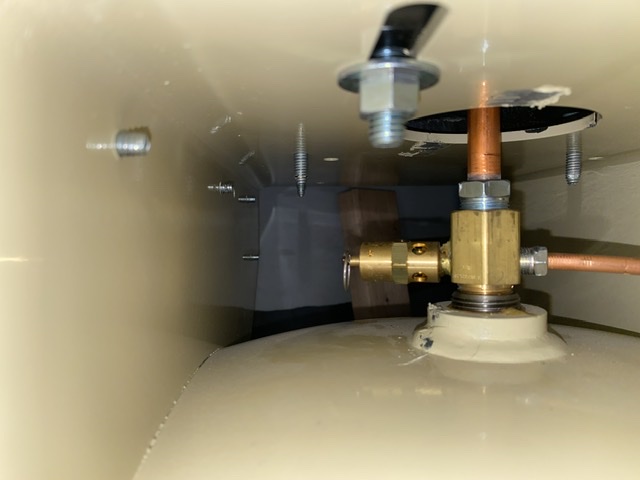

But what about the tank entry point? It’s plumbed for a 3/4 double flare (on 1/2 OD copper tubing). But it’s got the relief valves in it. Is there a 3/4 double flare adaptor, cause I can’t find one…

IR compressor? Based on the color and that fitting(looks just like mine) id say yes.

I just put an aftercooler and water separator on mine

Please let me know what fittings you used. I’m going crazy. Lol

What size compressor

Looks like a 1/2in ID line going into the tank like mine.

I used 1/2in OD tubing on everything else with 1/2in flare fittings. The fitting going into the tank is actually a 5/8 flare for the 1/2 ID line. I got everything at lowes and used the original fitting to secure to the tank in your picture. Had to use 2 90deg elbows soldered for the line going into the tank.

60 gallon IR. SS4L5 is the model.

My tubing from pump to tank measures 1/2 OD. I was hoping to avoid going to the store and manually fitting everything together but I think that’s what’s going to have to happen.

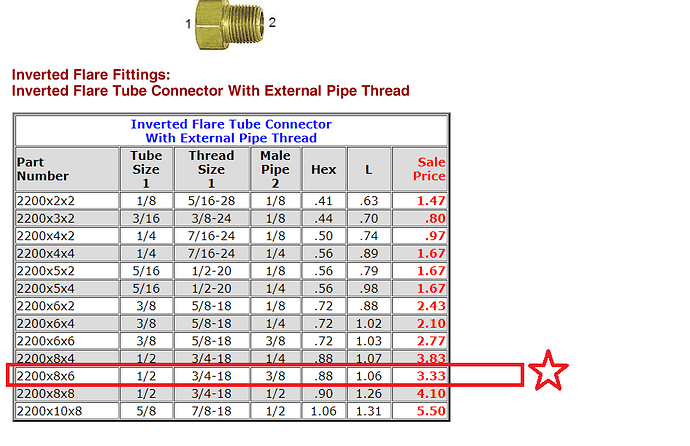

I think it may be this:

• Valve Inlet Threads: 1/2" Female Inverted Flare (measures about 11/16" inside diameter)

• Outlet Threads / Tank Threads: 1/2" Male NPT (measure about 3/4" outside diameter)

• Relief Valve Port: 1/8" Female NPT (measures about 10/32" inside diameter)

• Unloader Line Port: 1/8" Female NPT (fits 1/4" unloader line)

• Total Length: 2-3/4"

check valve has a 1/2" Female NPT inverted flare inlet and a 1/2" Male NPT outlet that screws into your air tank. On the side of this valve there are two ports: one 1/8" Female NPT for a relief valve and a 1/8" Female inverted flare fitting for an unloader line**

You can always change it out with 1/2"mnpt into tank, and 1/2" fmnpt check valve with dual 1/4" npt ports

Thanks, that helps. Half inch inverted flare sounds right. I’d prefer to not mess with the factory installed check valve though.

Still no easy search results for a fitting that would take the 1/2 inverted flare to 3/8 NPT. I’m just going to have to go mix and match. I just hate it when I can’t find things online.

Did you try McMaster-Carr (first) or Grainger’s (second choice). You should find it there & they’re shipping pretty fast.

Yep checked McMaster, and the fastenal link doesn’t have a male inverted flare to anything other than a female inverted flare.

I know a male inverted flare to hose barb fitting exists because I found one when working on my 4runner.

I’m going to try flaring my own new line. That seems like the cleanest, fewest amount of fittings way to do all of this.

I think that indicates the inverted flare is female on that fitting. I need a 1/2 male inverted flare to 3/8 NPT.

Sorry haven’t been on here a whole lot lately. @brownfox can you take a pic of your inlet to the tank? Yours may be different but I kept the OEM valve and just replaced the inlet tubing with my copper tubing, it was the same sized tubing/threading on both the compressor head and tank.

Well what a mess I’ve caused here.

Pump outlet has the adaptor that’s a female inverted flare. Outlet itself is 3/8 NPT I believe.

Tubing measures .50 OD, .38 ID. Threads on the nuts on the tubing measure .72.

Here are some pics of what I’ve got.

After obsessing over the proper inverted flare adaptor I finally found it last week at a place called Pirtek in a neighboring city.

1/2 SAE male inverted flare to 1/2 JIC.

The 1/2 JIC threaded right on to my 1/2 flare nut for my refrigeration tubing. It’s all up and running now. I’m preparing a brief tutorial and parts list for a new thread.

I realize my compressor placement is not ideal for airflow, but I’m in a two car garage and this is the best I can do. I also have a 240v to 12vDC converter I’m going to wire to the compressor so it kicks on a fan to cool the cooler. Although after cycling my compressor several times the cooler heated up. It may be helpful to have a fan keep blowing on it after the compressor shuts off just so you can start with a totally cool cooler sooner at the next cycle. Those are terrible sentences, sorry. Lol

Gigantic thanks to @sr71xjet for the guidance via PM.

What did you use for the cooler? Tranny cooler?

Looks awesome! I think you have the same size cooler as me. I notice zip ties at the top. I found mine got hot enough to melt the plastic fasteners I tried.

I found this fan on amazon. 10” muffin fan. AC Infinity AXIAL 2589, Muffin… https://www.amazon.ca/dp/B07P6VNMV7?ref=ppx_pop_mob_ap_share It does the trick. It’s kinda pricey at $100ish CAD. I’m sure there are better priced options around. I run it continuous while I’m cutting. I flick the switch when I enter the shop to cut. Turn it off when I leave. I can’t believe how much water I used to push through my plasma cutter!

Check out this thread for a list of parts and basic info.