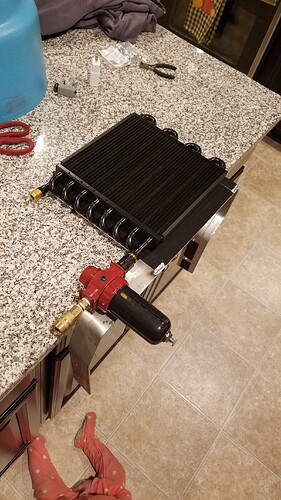

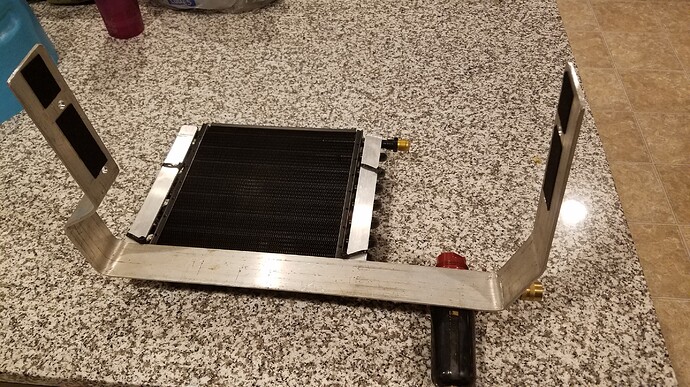

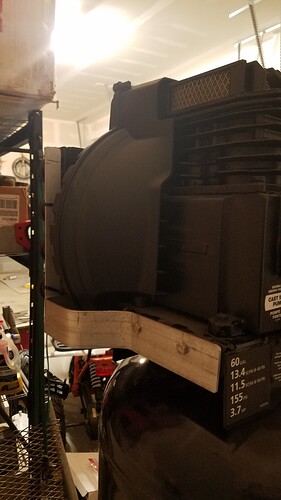

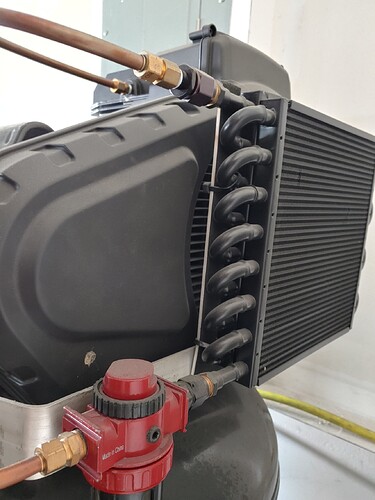

So i was having alot of moisture in my tank and tools so decided to try an aftercooler on my 60Gallon Husky Air comp. I used a med sized trans/oil cooler with a cheap craftsman filter/seperator afterward. The bracket i had a 3in alum strip i had laying around and just bent and trimmed to size and added 1in strips vertically and ziptied the cooler at 4 points to that. I was always using the filter/seperator but had never seen this amount of water collected in it before this setup. I am still getting some moister in the tank if anyone has any suggestions to help with that? i do have a small HF desicant before my Vipercut and seems to be ok just dont like having moisture in the tank still.

Test fitting in front of factory cooling fan and mounting using the factory holes

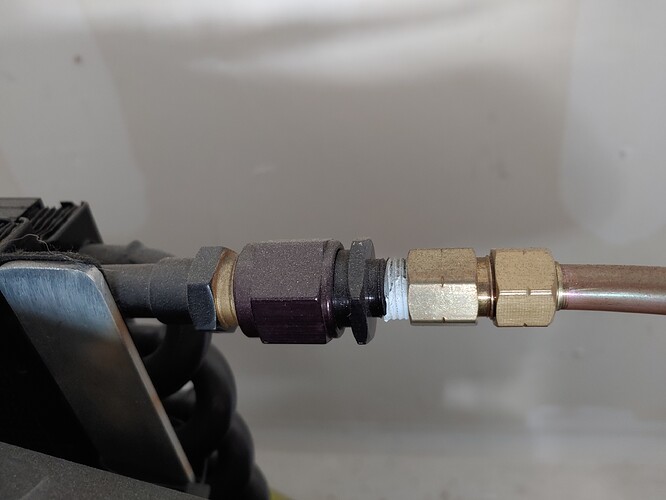

Copper tubing ran from head and to the tank

6 Likes

Fantastic setup! To help keep the tank from accumulating so much moister I added a harbour freight automatic compressor tank dump. When the compression relief on the tank goes when the compressor cycles it bleeds the bottom of the tank every time.

Thank you! Oh nice! Yeah i just manually drain mine every time i use it, seen alot of reviewers saying the tube on that kept bursting, have you had any issues with that?

Not yet. Easy enough to replace the tube if it bursts

I use one of those auto drains that has timer built in. They cost about $20-30. I have the same 60 gal Husky compressor. I am thinking about adding one of those HF refrigerated dryers.

1 Like

Absolutely love your design intent there! I’ll have to remember this when I upgrade my compressor. I recently did a copper manifold drain for my small setup. I’m just stoked that my compressor is in my small storage room outside of my shop. Love that your little is just sitting there watching you. That’s exactly how it is at my shop too! Makes it so grand!

How do you like your Husky, I see them all the time at the Depot Home, lol! I’m always drawn to them!

Awesome job on the cooler, I have the same compressor, what cooler did you use?

has it been working well?

I’m working on an after cooler right now as well. I have a new tranny cooler that I never got around to installing. I just haven’t taken the time to research what kind of tubing, fittings or flaring to do.

I don’t believe the tube that delivers the air to the tank is under much pressure is it? Doesn’t it just get hot?

Its under the most pressure, as its leaving the pump

Hmm. I would have thought it heads into the tank immediately and the tank has a valve that doesn’t let air go back to it. Weird.

That was my concern with picking a tranny cooler to use, being unsure of the pressure of the line. The tranny cooler I have is very thin wall tubing.

I’m trying to get together the parts to do this now. I went to EVCO but they said the only thing they had that would withstand the heat was 2000 psi hydraulic hose.

Is it soft copper refrigeration tubing that I want to buy? I want to plumb this as clean as possible, don’t want to use the flex pipe.

Yeah its been great! The line coming off the compressor to the inlet of the aftercooler you CANT touch cause is so HOT… but the outlet from the cooler to the compressor tank is always ambient-ish temp by just sticking it in front of the original compressor fan. Highly highly recommend some type of aftercooler. I am constantly draining the water separator after the cooler with minimal moisture in the tank it self. Where before, when I had just the water separator, it didnt really work cause the moisture/air was too warm still. https://www.amazon.com/gp/product/B004XONT3E/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

2 Likes

Im not entirely sure how much PSI on that line there actually is, but ive had mine pop off after the cooler and it wasnt a whole lot of pressure because its just being forced into the actual tank and building PSI there. I can say it gets really hot though!

So my cooler has AN-8 fittings that I had to adapt to NPT and fitted 3/8 copper tubing to it with pressure fitting, I didnt flare any of mine. I havent had any issues with running this setup since DEC 2018 when i insyltalled it

3 Likes

Thanks for the reply,

do you by chance have a list of fittings and diameter of both coper line you used? I’m not familiar with the different types of fittings and such

I apricate all the help

I believe this amazon listing has the fittings you would need. The OP lists the sizes he used for his setup.

1/2 NPT Female to 8AN Male Flare Hose Union Oil Tank Fittings Aluminum AN 8 to 1/2" NPT Fuel Line Adapter Black https://www.amazon.com/dp/B07ZCTLQ5Y/ref=cm_sw_r_cp_api_i_5cxKEbR4DWPGK

It will depend on what fitting the cooler you select has on it. From there it’s just copper refrigeration tubing from Home Depot I believe.

From what I understand any transmission cooler will work for this.

Nice job on the cooler you did it the correct way of setting it up by getting the dew-point down and condensate dropped out of your compressed air system prior to the air storage tank

A couple extra’s if you have a refrigerated dryer it should be routed this way.

Out of the final compression stage

Into an air cooled after cooler with auto drain

Into the refrigerated air dryer with auto drain and coalescing filter.

Then into the storage air tank with auto drain

Out of the tank into a particulate filter and a pressure reducing regulator

finally to the inlet of your plasma cutter.

If you live in an area that get’s below freezing be sure to heat trace. Another suggestion is a bypass on your auto drains this is to check to make sure they are working. If you real good at remembering to consistently drain the condensate as needed skip the auto drains.

just a suggestion from experience.

I would strongly recommend heat trace if you live in an area that any of your compressed air system can be exposed below freezing. The drier will only give you about ~40 degree dew point so it it get’s colder then that for any reason it will condense the trace remaining water vapor.

I"m trying to find the best fittings for doing this without having to use multiple adaptors, but it’s looking like that’s what we have to do.

OP, looks like you went with a female 8an to female NPT, then a male NPT to Male NPT to the tubing?

The tubing on my compressor is 1/2 OD with 3/4 threaded fittings going from pump to tank. The best I can find is a female to female 8an. I can’t find any female 8an to NPT, they are all male 8an.

So I’m looking at 3/4 to 1/2 reducers at the tank and pump with 1/2 OD tubing, to a female 1/2 NPT to female 8an to female to female 8an to the cooler.

I can only find one female to female 8an through Jegs. Not sure why, I just don’t like using lots of adaptors, does it matter? I also don’t like the idea of reducing the tubing size the would be connecting the cooler to the tank and pump, does that matter either?

Alright finally found it.

Aluminum Female 8AN Swivel to Male 1/2 NPT Thread Fuel Pipe Hose Fitting, Straight -8 AN 3/4-16 to 1/2" NPT, Black https://www.amazon.com/dp/B07M6613QJ/ref=cm_sw_r_cp_api_i_A6ZMEbC6P1FRG

Is that a water separator on the back?