I haven’t done any cutting for profit yet, just personal use and gifts. I had someone ask me to make them a sign approximately 30" tall by 48" wide. How would you figure out what a fair price is?

I didn’t create the image it was provided as a .jpeg

I have always thought that if I were charging, it would be double the cost of the metal plus something like @FamousElementsStudio notes here for $0.25 per pierce and $0.14 per inch charge.

It is one of those things that the market will show you what the price should be.

The way I price my stuff is I double the cost of my materials. I charge 100 a hour for table time approximately .03 per second. Then depending on how they want it finished.

That sounds way easier! Do you have a minimum rate?

Not really … I do have a friend rate .![]() .( keep in mind friend and buddy’s are different)…

.( keep in mind friend and buddy’s are different)…

Now if there is a lot of design time you may want to charge extra… honestly no one but ourselves can price our personal time.

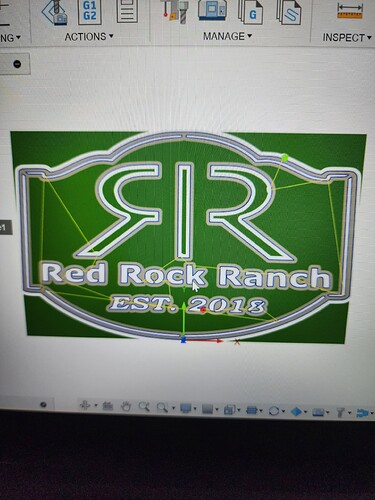

Super simple and if you need any help let me know if you use Fusion. Few minutes and we could have it cut ready. I would do a little work on letters and that outside border scares me because they can flex when you cut them with long distance between the connection points if using 16ga or less steel. If bolting flat to wall that shouldn’t be an issue. Big question is how they want it finished which can get expensive. (spray paint vs powder coating)

Thank you for all the input, i’m decent with fusion 360 so i could trace it if i need to. Im going to try my hand at inkscape and trace bitmap I haven’t been able to get inkscape to work for me yet, but i’m more of an engineer type mind than an artist. I need to talk to the potential customer and get more details on the finish they are looking for.

You might try convertio.com and convert to SVG. The fact that it is two colors, it should give a decent first result to insert the SVG in Fusion 360.

Edit: I see it seems to have a watermark but you should be able to remove easily with converting to 2 colors.

I traced bitmap in inkscape then imported into fusion as an svg. I also resized it. It looks good on the computer from what i can see.

Not sure what water mark your talking about? Can you point it out so i dont miss it some how?

It is probably because you took a photo of your monitor…nevermind ![]()

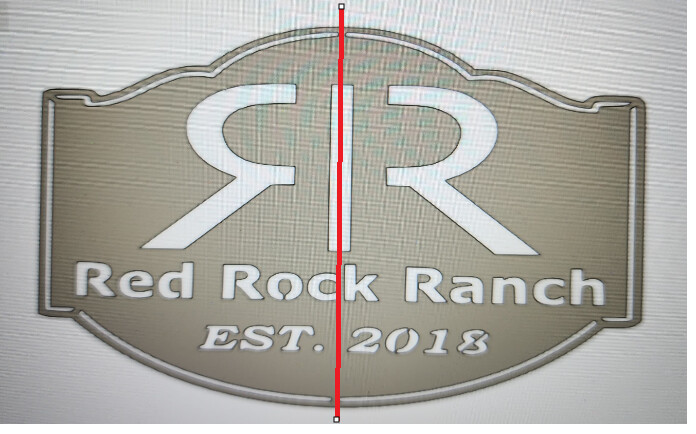

But you might check your bridges that support the internal structure of the letters. If they are less than 0.1 inches, you may run the risk of them not being strong enough to support the centers. Sometimes 0.11 inches is even necessary.

The “e” in “Red” looks like it might have enough support. That is why I made it green.

Edit: I missed the “d” in “Red”…it looks like it chokes down pretty small as well. And, of course, it you find the “0” and the “8” to be small-ish, I would increase both the top and bottom bridges. The center of the “8” would be up to you and how it looks.

Thanks for the insight i will check how thick they are.

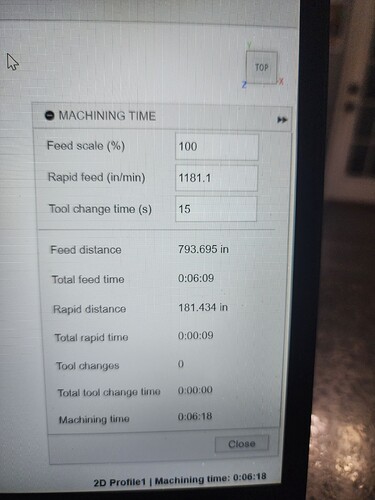

So this is the cutting data. I need to ask what material and finish they want tomorrow. At $0.03 a second it comes out to $11.34 for cut time plus double the materials. Ill figure out material cost tomorrow. The other method comes out to $118.91 plus double the materials… these prices are pretty far off from each other. Any thoughts on which way is a more fair price? Or if theres something im not doing right in this calculation?

With this type of sign I like to split it down the middle and get one side perimeter how i want it and mirror the opposite side perimeter. This sign look really close but just something i like to do. Post pic if you cut it. cool sign!

Good technique Don. Just how Inkscape works, it takes a guess on shading and does not assume symmetry. Looking at the top arches and curves, they would be expected to be gentle and there appears some undulations in the line and they are not symmetrical from one side to the other.

Of course, we are looking at a photo of a monitor screen so it is probably better in person. But, still good tip.

Honestly it depends a lot on location. … where I live most people don’t have the money.

If you go to e-commerce sites like Etsy and see what similar things sell for… then wonder how many do they actually sell plus they are shipping

thats included in most prices.

Then remember you have to start somewhere. I price 100 a hour that will cover my machine. Doubling the material is a little money. Then your finish. I powdercoat everything. If someone wants wet paint I will charge more.

On my finishing my oven costs me about $3 to run it for a cycle. I charge about $10. I try to do batches to help a few out. Most powder I use cost about .75 a ounce so I weigh before and after on certain jobs but most I can guess.

Now figure how much hands on time you have finishing the part. How much do you want to pay yourself.

Then I consider make money and give a good deal so they may recommend you to a friend.