Use Neodymium magnets. Its amazing how strong they are. You can find a bunch of them on Amazon.

Thats awesome! Although these might not work for mine due to my Parallel set sticks out past the vise since the vise is narrow. Sure I could cut them down but I use them for my vertical mill as well.

These are still pretty cool though and would work for the manual mill.

The magnets I used I already had just laying around and you cant beat free haha

I’ve never seen the magnet hooks before, those are cool. I play a lot with magnets but to hold parallels my go to solution is a flat spring made from shipping banding.

Free as everyone on this forum received some with their machine! Cut with tin snips and bend by hand and ta da!

I do similar at work. I bend them in a Z shape though.

I have lots of them in various shapes and sizes. It’s a very handy material to keep around.

That’s a fact I work in a recon shop we we repair parts. Lot of parts are casted if it won’t level yeah got to shim it.![]()

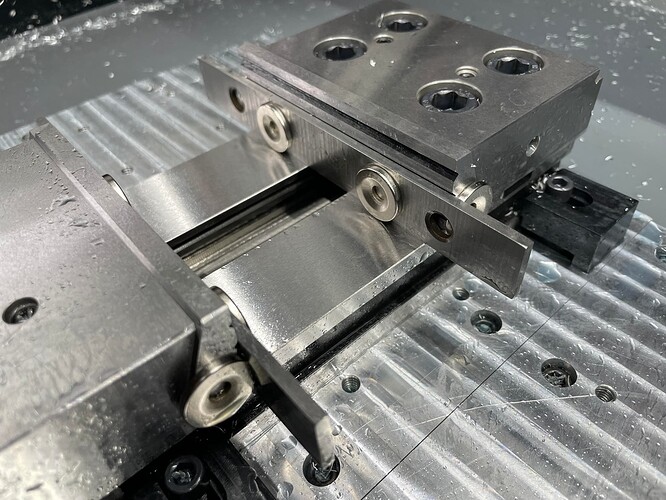

![]()

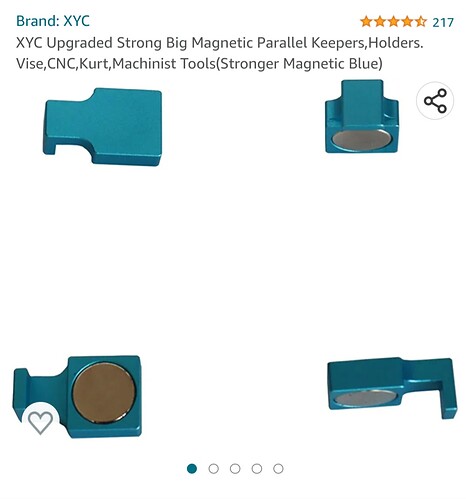

![]()

Freaking love it! Never would have thought! My hats tipped ![]()

I am sure this is a really dumb question but how in the heck does someone purchase another low-profile vise off this website?? I go into build the MR1 and it doesn’t give an option except to purchase the machine again and wants to send a quote. What am I missing and does anyone have any other good options to purchase elsewhere?

You have to contact support.

Ah that kinda stinks but makes sense now. Thanks

Someone with extra cash laying around should order a bunch and undercut Langmuir lol

Makes sense why mine was full of grinding swarf lol

We have the bases custom made to be lower in height and 10” opening. You can buy GT100 vises but they’re taller and much shorter (~4”).

thats a pretty good deal with the clamps too.