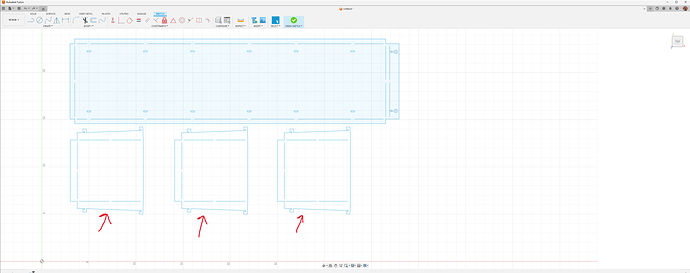

i got this mail holder off the file share and these three parts dont have a body so i can extrude. they are just lines. how do i fix that so i can extrude and go from there?

If you share the file it is easier for us to explain and demonstrate.

The primary reason that it won’t make a body is that a body requires an outside contour that is connect. And yes you are right: a single line will not make a body however a single line can ‘extrude’ cut a body.

What is pictured is not a single line but is a line the eventually ends back where it started: that is a contour.

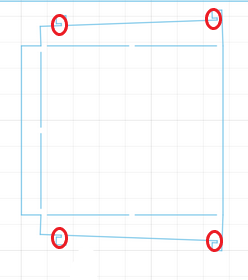

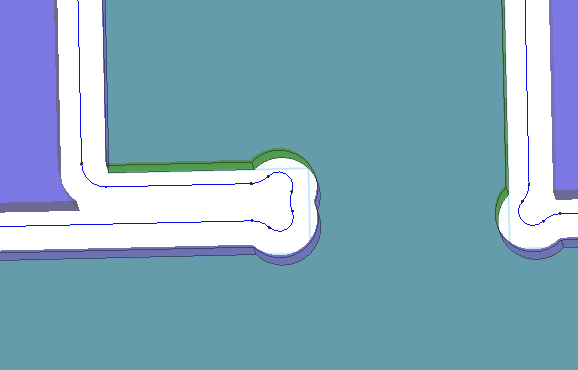

If you zoom into these areas, you will likely find where the connection of the contour is broken.

There are many reasons for a contour to be broken. A few common issues:

- two lines don’t join at the same coincidental point

- a line overlaps a line but is hidden

Look for a white dot with an open center. That might be a clue, but not always.

Mail Holder.dxf (120.2 KB)

sorry heres the dxf

and the lines look fine unless im not lookin right XD

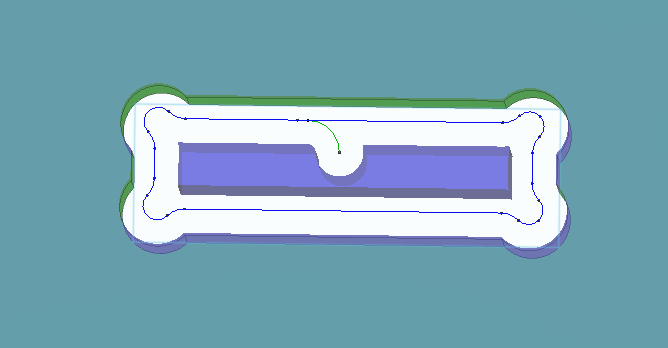

In each case this line was the problem. I deleted it and replaced it and the profile came alive. Sometimes you just pick the right one.

This should work for you now:

Mail Holder v1Chelan.f3d (58.6 KB)

thanyou thankyou thankyou for that. yes that worked got it ready to cut now. sorry for the late response i fell asleep lol

Never apologize for sleep unless you are driving or using sharp tools at the time! ![]()

That reminds me of one of my favorite jokes:

“I want to die in my sleep like my father did and not like all the screaming people with him in the car.”

You are likely to run into a few problems with this design:

-

I did not take care importing with metric vs inches so double check the measurements with what you are expecting.

-

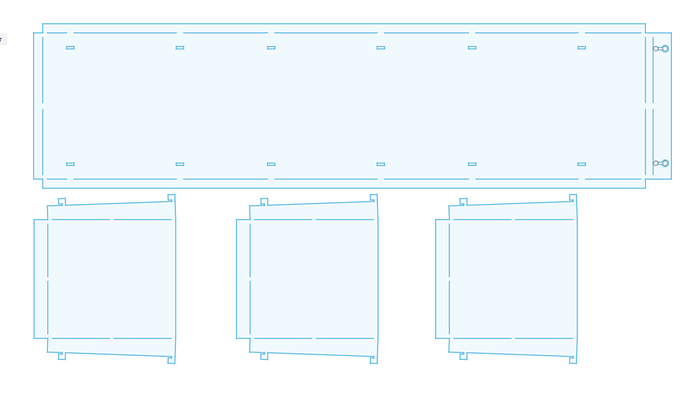

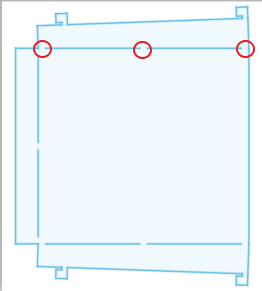

During Manufacturing, I could not get the tool path to grab the slots (it kept discarding them) unless I picked a Preferred Lead-in Position for each and every slot:

-

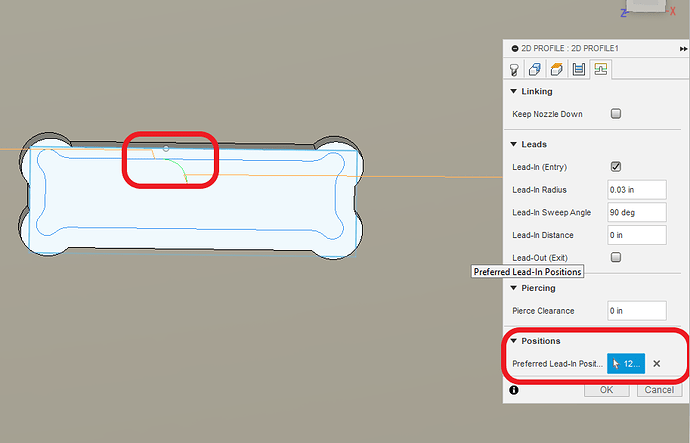

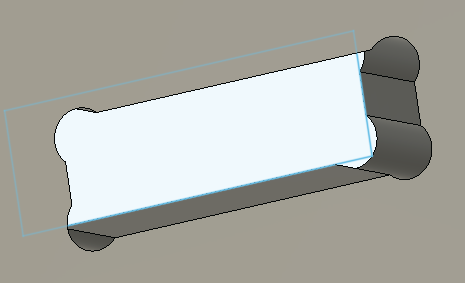

Since you are dealing with slots and having the metal require clearance, the plasma torch is not going to clear all the metal away with a standard square cut. Notice the uncut metal left in the simulation:

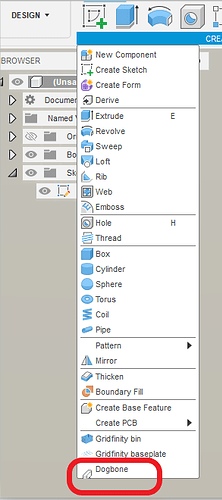

4a. To deal with removal of this extra metal, “dog boning” is the most often used technique. Fusion has a Dogbone features but I must admit, I don’t know how to use it.

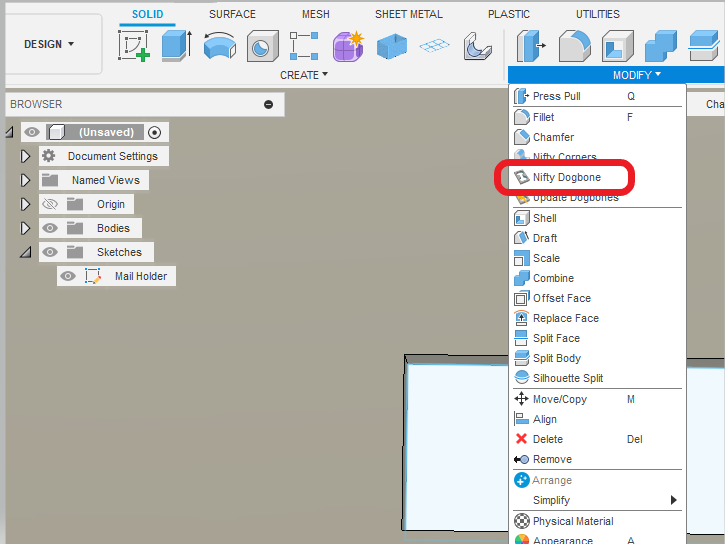

4b. I use a purchased dogbone tool called “Nifty Dogbone” and it is very slick. (I believe either one needs a body to apply to your design. It cannot be used on a sketch.) Once installed, it lives in the “Modify” section.

Here is a link to the Nifty Dogbone add-on for Fusion 360: Nifty Dogbone for Autodesk® Fusion 360™ | Fusion | Autodesk App Store

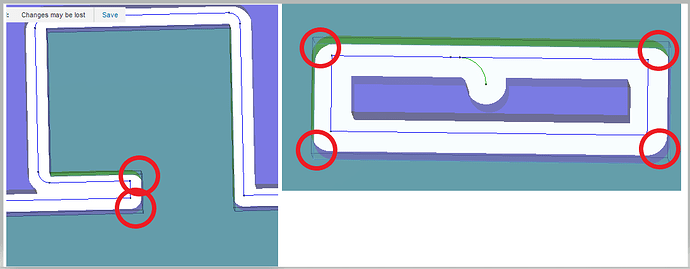

- Here is what it does to the CAM operation:

Mail Slots Dogboned Chelan.f3d (429.5 KB)

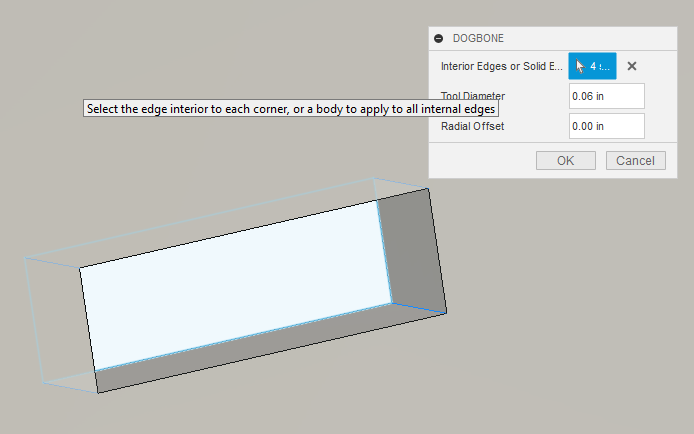

Edit: I actually explored the included Dogbone tool in Fusion and it works fine but is very manual. You pick the edges that you want dogboned and I picked a dimension for the “tool diameter” of 0.06 which is more than enough room and then click OK. It is much more labor intensive than Nifty Dogbone but works fine.

I found a way on another topic when i get power again i will find and link it so we can all understand. Maybe it wont work but ill add it so you smart guys can tell me. Lmao

i used the first video to ad relief cuts / bend lines

I am not sure we are talking about the same thing. Those relief cuts are a good idea and should work fine to help bend the metal. Depending on what gauge of metal you are using, hopefully you have left enough metal to support the “basket.”

I am referring to having room to allow the metal tab to have room to lock into the slots on the base plate.

i think so but i might make them shorter to be safe thanks. never crossed my mind

The quick and dirty way to figure out how much material to leave is to cut a strip of metal, perhaps 2, 3 or maybe 4 inches wide. Bend it with whatever means you plan to bend your current project. If you can bend the 2" wide strip easily then you could safely leave 2" of material (adding up all of those gaps between the relief cuts).

So if you are only leaving a total of 1 inch of material and you know you can bend 2 inches, then you are missing out of some additional strength you could leave.

The other idea is that you can add the strength back after bending by doing some stitch welding on the inside…depending on your welding skills. I am mediocre with welding.

Probably overthinking the whole thing. We are talking mail slots/baskets! ![]()

I understand where you are coming from and i have added 1/4 to 1/2 an inch so there should be plenty. I would hope anyway. I guess we will see when i make it ill update accordingly.

You will be fine.

I like to think of this this way: Every project that you do affords you the opportunity to create and learn. That is what it is all about, as far as I am concerned. That is the spice of life no matter the adventure.

There is not a project I have done, that I don’t look back and say “If I did this again, I would have done…”

Well, maybe there were a few that checked all the boxes. But, you know what I mean.