Been using a hypertherm powermax 45 with a cpc port and a hand torch. A jumper wire was put in where the quick connect is to run it. Now have gotten a sync 85 with a cpc port and want to run it the same way the the quick connect end is different with more wires and apparently isn’t the same as the 45. Does anyone know how to do it with out splicing wires? thanks

Just buy a machine torch.

was hoping to avoid spending another grand for a small hobby table

At this point I would not recommend trying it as it has a chip in the torch and may cause trouble with the plasma cutter.

You could contact Hypertherm and see if they have a way to do it with out any damage to the torch or cutter.

But you bought a machine that’s worth more than a table ![]()

I guess I don’t understand the logic. I use 91 in my Corvettes. The SUVs just get 87 octane.

I wouldn’t put 87 in cars that warrant 91. I wouldn’t use a hand torch for CNC powered by a nice machine either.

Your wanting to use your old 45 torch on your new 85sync? They are not interchangable.

I temp hooked up my 65 sync hand torch by wiring the cpc port with the correct wiring. It worked fine. You’ll have to wire the cpc port with a machine torch also.

No im wanting to use the sync 85 torch. I bought the cpc wire but the trigger safty is keeping it from firing

I guess you dont understand the budgeting of money on a small farm then. The bigger plasma was more important for repairs than a bigger table. Not everyone is forunite enough to buy everything they want or need. Thats the logic

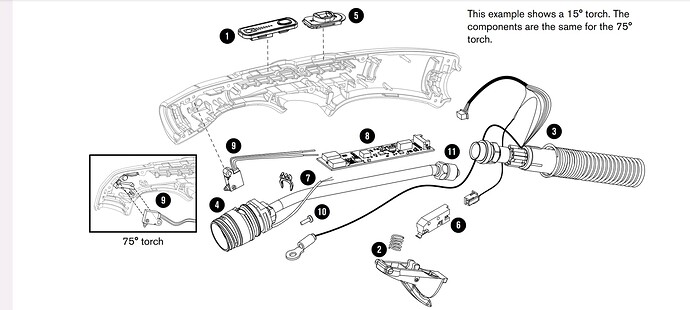

This is the full service manual for hypertherm’s sync torches.

It includes a lot of details including a good picture of the colors of the wires from the trigger switch.

Some of the information in this manual May shed some light on your situation.

I run a sync adapter so I don’t have the same torch.

And here is a link to the operator’s manual

And a link to the service manual

This service manual does have a lot of breakdown diagrams.

Edit.

But the very real and likely possibility remains that there will be some kind of software lock that’s looking to see whether the torch trigger is an open or closed position which is also tied to the CPC port.

ok thank you for the help

Please let us know how you make out and keep this topic updated.

I’m sure you won’t be the only person running into these questions in the future.

And when you’re up and running come back and post some projects. We all like to see what people are doing with their machines.

On a farm I’d imagine a lot of interesting projects come up.

Then I hope the info you find works out well for you.

I’ll still recommend a machine torch after everything stated though. Having to do repair work, there’s a lot of convenience to be had running a dedicated machine torch to the table, and having the ability to run a hand torch off the table.

Having a separate consumable set for gouging, etc while the table is strictly used for cutting.

Getting the machine torch will free up the plasma cutter for other projects or needs, that don’t require you to unclamp the hand torch from the z axis, and the hassle of squaring up each time.

I have the 105 sync with machine and hand torch on a XR. As said above the sync uses a cartridge which the machine reads to set the power level, You can still adjust the power lower but not above. Unscrew the cartridge and the machine goes into fault. So not sure you could use your powermax torch with a sync as it wont sense a cartridge and fault… The sync hand torch also has power control built in so you can adjust power on the fly. Explains all the extra wiring.

If you want to use the Sync I think you have no option but to purchase the appropriate torch. Sell your power max and that will fund a machine and hand torch for the sync.

There’s a setting to override the safety. It’s in the owners manual somewhere.

This topic does have me thinking it would be possible to maybe 3D print a handle for a machine torch so you can use it for hand cutting.

The idea seems cumbersome at first but depending on the handle design and the balance point it might be quite comfortable.

The handle could also have a trigger which was connected to the trigger activation on the CPC port.

So maybe with some 3D printed parts and a switch somebody could have access to hand cutting and machine cutting with one unit.

Not a ideal solution but potentially a solution for somebody who only wanted to purchase one torch and wanted to both hand cut and use the table with a Hypertherm SYNC.

So what would a 3D printed handle that clamps onto a machine torch for hand cutting look like, Any ideas?

Edit:

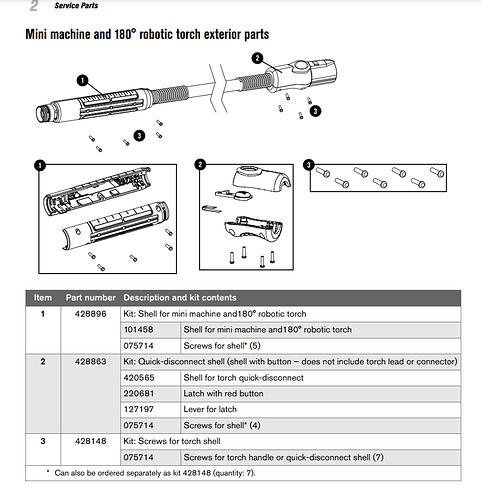

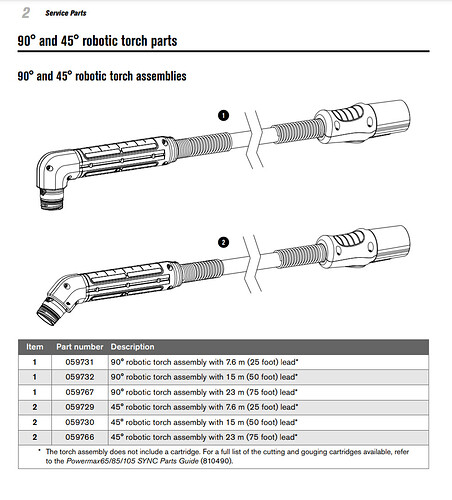

With a little more research it turns out that they sell a few different versions of the mechanized torch.

So there are optional shaped torches that are more hand-torch configuration to start with for this project.

This is all just pure theory right now.

Check out these part numbers from hypertherm

This is a little late in the OP’s case but maybe for a future reader

Now I just had another brain wave that might help the OP. What if the PCB inside the hand torch could be changed for the machine torch PCB then wire the hand torch trigger to the CPC Port triggers pins when in hand operation.

I wonder what the circuit board would cost?

And obviously this is all speculation and at any readers risk.

If Hypertherm is intent on controlling their machines and torches, it resembles a John Deere scenario. People should reconsider purchasing their products. While the machines are impressive, compelling consumers to buy $50 consumables is unreasonable.

Lots of options on the marketplace. My two cents.

BTW @Rhen Welcome to the forum

I’ve been getting a lot of life out of my sync cartridges.