@langmuir-daniel I plan to use the MR-1 mostly on mild steel and stainless, is this recommended and if so how do I add it to my order?

The main advantage of the bigger Z drive is increased thrust force. This is especially handy for drilling harder materials like steel and stainless. You can certainly drill holes well on the standard driver, but you can run higher chipload on the bigger driver.

Go to support page for the MR1. Click on add items to my order. The part is plug and play. Just remove existing controller from inside the control box.

I emailed support and got it taken care of. I had issues in the past doing it through the website. I tried adding the machine torch to my pro order and the system still made it a separate order and shipping.

Quick question on wiring:

I didn’t realize my control box would already have the Z-axis upgrade installed when I ordered the additional high powered driver, so I’m replacing the X-axis driver instead. That said, can anyone explain why the polarity on one side of the wiring harness gets swapped instead of matching the wiring configuration for both pairs of wires from the old driver to the new driver?

@Cpt_UhOh Stepper windings and their corresponding drivers are polarity sensitive. Switching the polarity for a given winding will change the rotation direction of the stepper. If I remember correctly, the polarity markings on the drivers are different between the standard and the high torque variants and therefore swapping the wiring is necessary to keep the stepper operating the same direction.

I think the wire swap is just because the High power unit has the wiring postions in different locations. I have them in all the locations. Big improvement over stock configuration. But certainly not required.

Hi Guys,

Thanks for the replies. I understand the necessity swapping the wires to adjust for polarity differences between wiring harnesses, but that’s what makes this confusing or at least non-obvious.

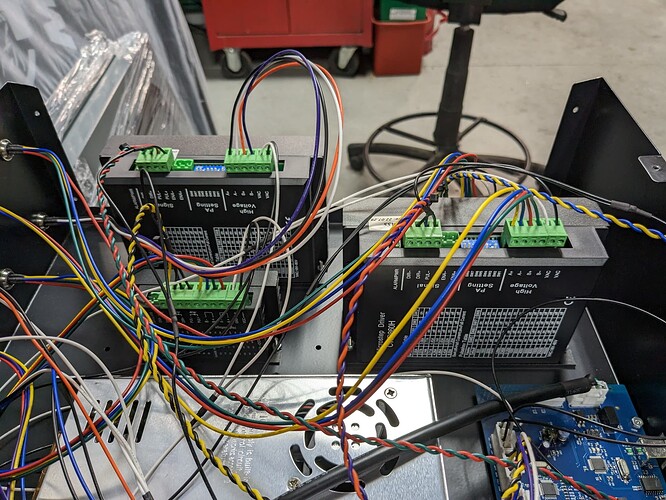

Take a look at the pic of my drivers after installing the new X upgrade per the instructions. The wiring conventions don’t appear to be held constant between the new unit and the others, either by position in the harness (A\B +-) or by DCV color code (i.e. Z drive yellow = A+ whereas Y drive yellow = B-)

If the provided instructions produce a working result then it’s correct, I’m just curious why.

I also questioned the differences between drivers but couldn’t find where anyone had a problem after the wiring swap, so I went with it.

I figured if I powered it up and got a smoke show then it was going to be a call to Langmuir to discuss a replacement. But all is well and I’ve had chips flying for a little over a week now with no problems.

Good to know. Thanks.