Today my package from Langmuir arrived. 2 additional High-power drivers for the Y and X

axis motors. My machine already has one on the Z axis.

Installed them at lunchtime and got the machine fired back up.

I can tell you they both travel with authority now. I didn’t have time to test it out today but, I will keep you guys updated.

Might consider doing same for mine. I can hear a missed step on the Y axis during rapids, took me a minute to figure out what was going on. Once I tested at different speeds it no longer did it. Went through and resquared the machine and reset the opposite Yrail for parallel just to be sure. It doesnt like 100ipm travels.

Did the new steppers require ooening the box to change the drive unit? Guessing yes like Z-qxis upgrade.

Yes, you will need to remove the control box from the mill. The screws are behind the rear leg. Open the enclosure and replace the stepper drivers. Follow the directions for the Z driver and flip the green and the red wires on the plug. It takes about 30 minutes to complete. I keep you updated on the performance increase if any.

did you just order the z driver upgrade or is there a special one made for the other axis and how did you find out you can do this/

Just order two z drivers. They are the same.

ok good deal thanks

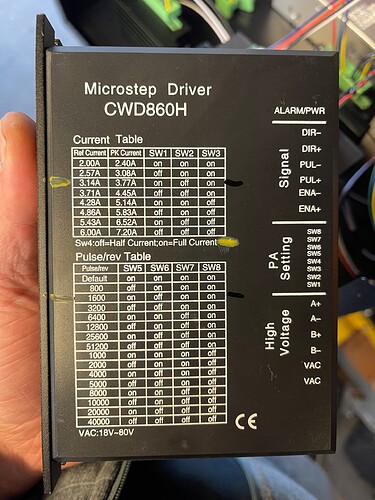

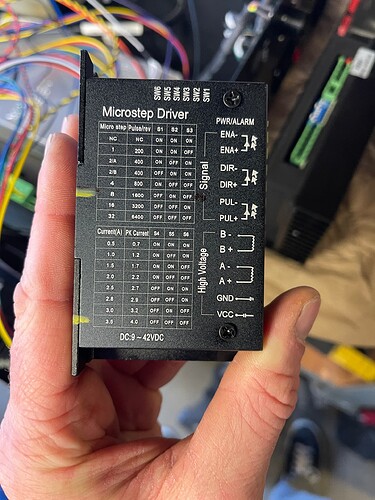

Im no steppermotor/ driver expert but I was comparing the dip switches and settings between low power and high power and saw something interesting. The pulse per rev is obviously the same between the two but on the small driver the current is set to 3.5 with a peak of 4 amps, on the large driver its set to 3.14 amps with peak of 3.77. The large driver is able to handle double the voltage but no power supply changes here. Seems like the new driver would at least be set to 3.71 with the 4.45 peak but maybe there’s some additional area under the power curve that isn’t shown in these settings. I’m sure we could probably dig up specs on these motors and see what is safe. I assume the giant Z and X steppers can take 50% or more current then the smaller Y motors. See photos, Yellow paint marks are the dip switch settings as shipped. Large driver top photo, its about twice the size lol.

EDIT: if anyone wants to take the plunge they are about $50 on aliexpress

Will get with Daniel and see the recommendation. Good catch…

The word from Conroe is that these high power driver need no dip switch adjustment.

With that being said, my machine is performing well.

do they tell you how much it increased torque on the other axis like it does on the z-axis?

Any reasoning or just an answer?

just wondering.

Told me no dip switch adjusting required. These are the same motors and controllers they have used on the XR platform for years.

So when they come out with the 200ipm kit is that a motor upgrade or drivers or both?

Don’t have that answer for you.

From what I’ve read in another post its just the drivers, but its not 100% clear. see post below towards the bottom.

I’m pretty sure they mentioned different pitch ball screws also…

@Bigdaddy2166 , I think I am missing steps at high rapids on Y and was thinking on upgrading stepper motors and drivers like you did. The question is will the driver upgrade be enough or should I upgrade to bigger motors like X and Z? Did you notice really a big improvement with only the drivers?

Thanks

No is the short answer. My stalling problem has disappeared though. I don’t believe they were a waste of money. I rarely take heavy MRR cuts on steel though. I rather watch it for an additional 5 min than excessively load the spindle.

Did you also change the stepper motors on the Y axis or left them original and just upgraded to bigger drivers?