Simple is beyond F360 evidently.

Still trying to do hole tests, and it just won’t post right.

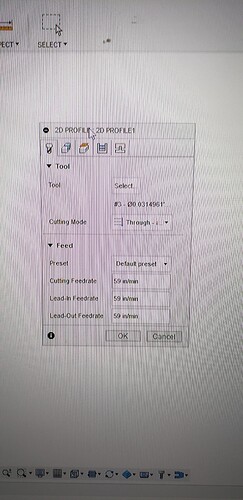

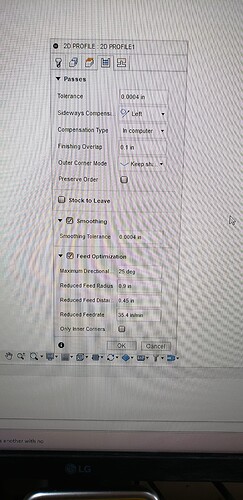

2 .685 holes .985 between centers, left and right closed chain, smoothing and feed optimization.

I should add that I get an IHS fail at the second hole, even after I add a m30 at the end of the first cut.

(v1.6-af)

G90 G94

G17

G20

H0

(2D Profile1)

G0 X-0.2525 Y0.2268

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.25 (Pierce Height)

M3

G4 P0.95

G0 Z0.1 (Cut Height)

H1

G3 X-0.1525 Y0.4 I-0.1 J0.1732 F59.

G3 X-0.7475 I-0.2975 J0. F35.4

G3 X-0.1525 I0.2975 J0.

G3 X-0.1691 Y0.4981 I-0.2975 J0.

G3 X-0.3207 Y0.6287 I-0.1888 J-0.066 F59.

(2D Profile2)

G0 X0.6725 Y0.5732

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.25 (Pierce Height)

M3

G4 P0.95

G0 Z0.1 (Cut Height)

H1

G2 X0.7725 Y0.4 I-0.1 J-0.1732

G2 X0.1775 I-0.2975 J0. F35.4

G2 X0.7725 I0.2975 J0.

G2 X0.7559 Y0.3019 I-0.2975 J0.

G2 X0.6043 Y0.1713 I-0.1888 J0.066 F59.

M30

(PS0)