I run fine cut tip with hypertherm 45xp on these types of signs using 16ga and try to stay away from having lines less than 0.1” of each other. I can quickly cleanup that bronco dxf but cutting that small you would lose a lot of cool details. I would double that but few spots I would clean up prior to cutting myself.

@ChelanJim Right on! I’ve been wondering how this procedure was accomplished. This is a huge help. Thank you.

I don’t think I said it very clearly but do your first toolpath with reasonable cutting settings for the best quality. It will throw an error(s) as it will skip the small contours that it can’t cut with those lead-ins. Ignore that error.

Then start another toolpath and if you keep the other toolpath visible, you can usually see what contours were skipped. Those are the ones that you have to go gorilla on and decrease all of the niceties (decrease the lead-ins to miniscule amounts).

You may need to do a third path for the single lines since they are a total different animal. (They will need the center compensation and no lead-in, no lead-out and never any pierce clearance.)

The last thing you need to do is to drag those tool paths into the order you want them to cut. Simple. Just left click and hold and move it where you want it. The last tool path will be the one that is cutting the major outline.

When you go to create the gcode, make sure none of the tool paths are highlighted: otherwise the gcode will have ONLY that highlighted tool path. You want the Set-up highlighted, not the individual tool paths.

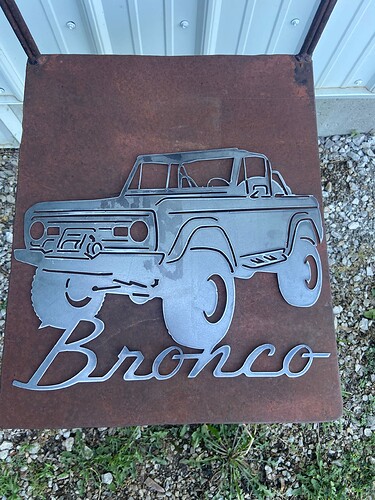

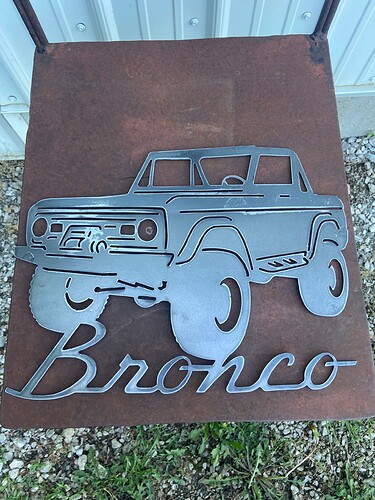

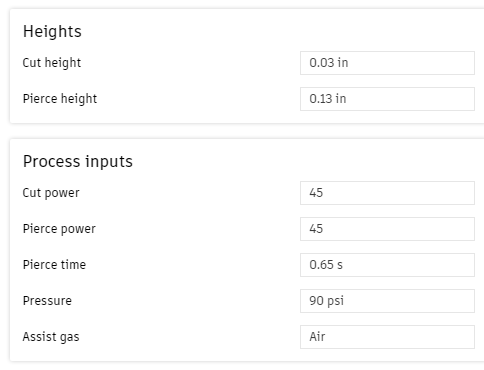

@DonP So with using your suggested settings I loaded onto the table. First results as you suspected needed to be cleaned up or scaled up in size. First photo is just running it as is with a couple of the grill lines taken out. Second photo is with me going back in and cleaning up some spots and getting rid of some detail. (For This Size) it’s definitely not the best but this is all a work in progress and this was a great piece to learn more of what is possible and what isn’t when it comes to scaling and tool paths, setup etc. Yours and everyone else’s help was much appreciated. I need to look into finer tips and dialing in my amperage and IPM to help with dross. This was all cut using 16g @ 28amps and the default settings for IPM. I’m not completely sure how to adjust the program IPM whether it’s in fusion or Fire control itself.

@DonP Second Photo

IPM is set in your tool in Fusion 360. It could be changed in your tool path edits but would be very tedious. IPM for cutting and lead-ins and the kerf width. That is basically all that the tool in Fusion has that is used in the g-code.

None of these things in your tool actually makes it into the g-code from the tool:

Those look great! Your really off to good start and the more you cut and design the better you’ll get. This forum is great place to ask questions and so many knowledgeable people willing to help. I’m weekend warrior myself and do this for fun when I have time.

This is something I’m going to play with. I appreciate the walk through, I really do. This thread has already heled me immensely. It has been driving me crazy trying to add the finer detail without sacrificing the quality. Or being able to generate complete toolpaths. I will be sure to keep you posted on this thread.

You can send private messaging if you prefer. Just tap on the users profile picture and you will see the link for “Message”. It will earmark the message with the current topic.

But public questions have value as well. Often times, others have good input. And, we all learn things in different ways. Plus, someone else may have the same question but didn’t know how to ask it.