We finally have the machine totally up and running and would appreciate some tips on adjusting the settings for cleaner cuts. We are running the crossfire xr with the razor weld 45. We have an industrial air compressor with a particle separator and an air dryer. The settings used for this cut:

Feed rate: 140 in/min

Tolerance: .0004 in

Lead in radius: .02 in

Lead in sweep angle: 60 deg

Lead in distance: .07 in

No lead out

Pierce clearance: 0 in

Cut height: .063 in

Ihs spring back: .02 in

Pierce delay: .2 sec

Pierce height: .15 in

45 amps

100 psi on the air compressor

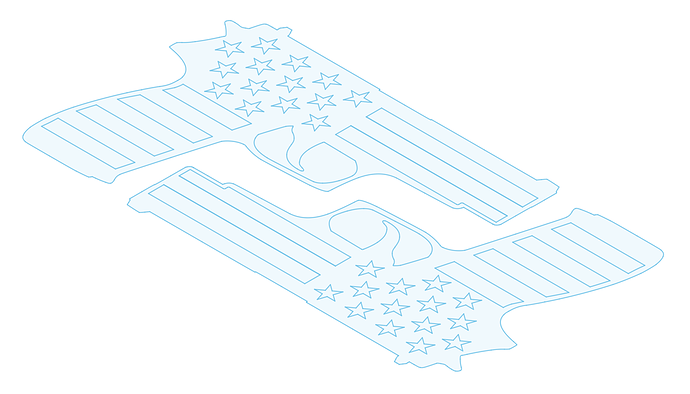

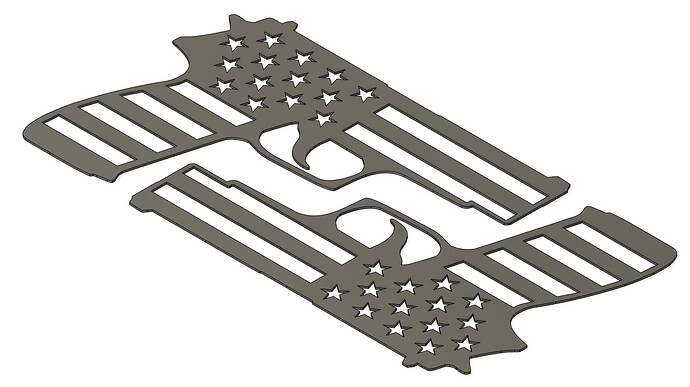

Stars and stripes pistol v2.f3d (435.6 KB)

I took a look through your F3D file. there is a couple changes I would make.

- Extrude your sketch profile into a body before proceeding to the manufacturing work space.

this will simplify the toolpath delovopment phase.

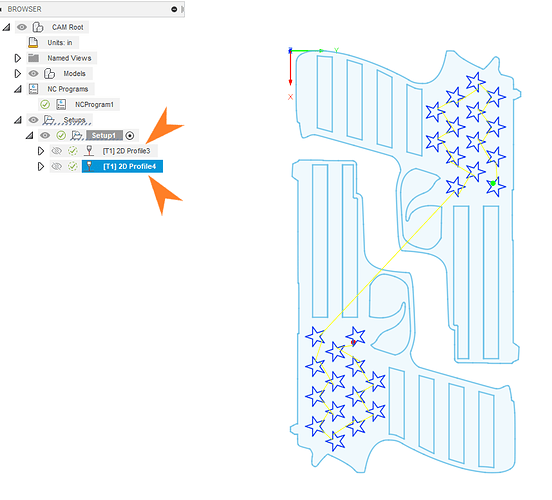

- Operations should be switched so all the internal geometry is cut before the outside.

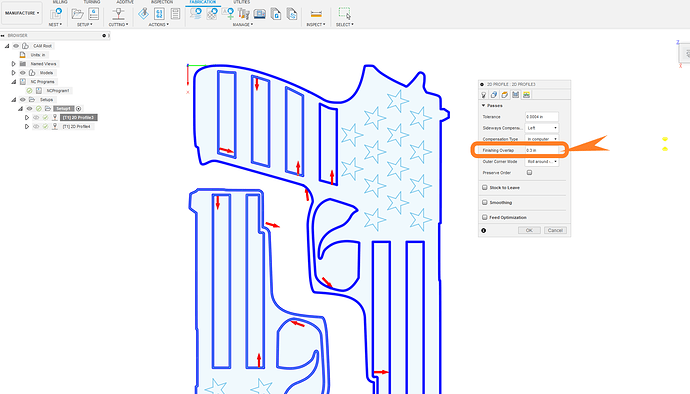

- I would switch out the finishing overlap for a lead out on thinner materials.

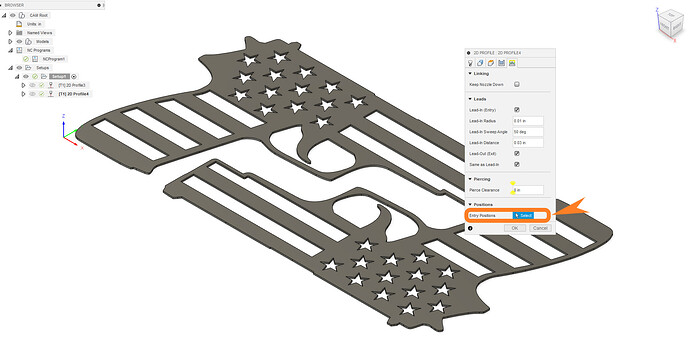

- some of these lead in are very close to the cut line you can select “entry positions” to have these start in better places.

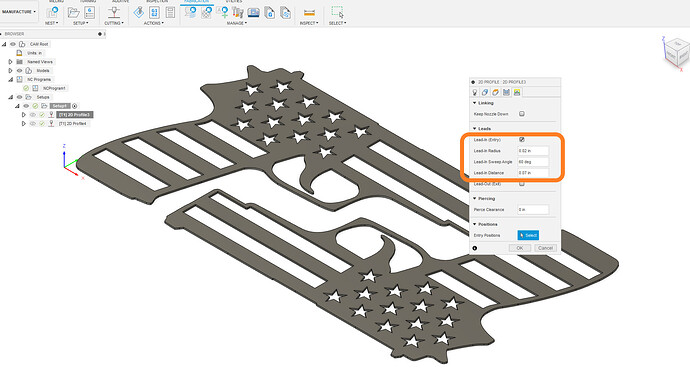

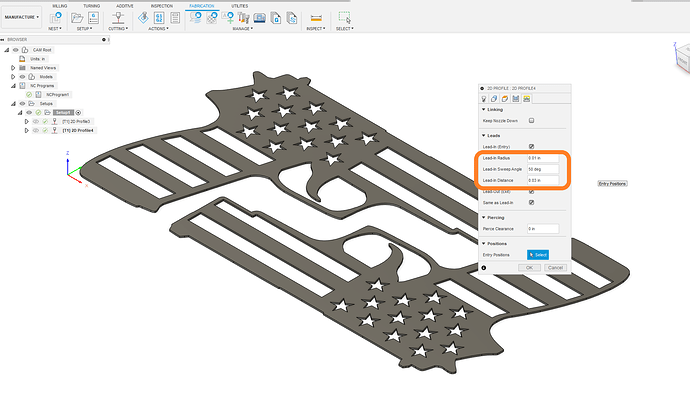

- your second operation has different and very reduced lead in radius , lead in distance and sweep angle then stated above? also there is a lead out on the 2nd operation.

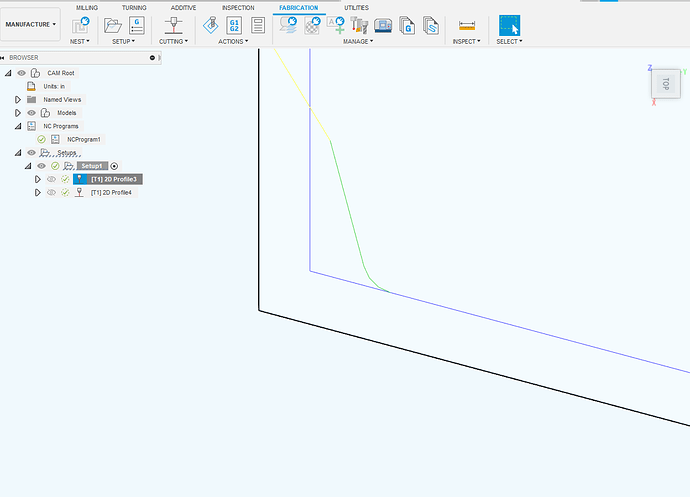

operation 1

operation 2

- try to increase your lead in distance length and add a lead out where you can.

attached is a F3D file I modified and a NC file created from it.

Stars and stripes pistol tin mod v2.f3d (807.7 KB)

Stars and stripes pistols.nc (44.0 KB)

3 Likes

Thank you! That helps!