Soooooo… I have read a mind numbing amount of posts and I still can’t seem to find what I’m looking for. What I’m looking for is advice, experience, and possibly pictures of set-ups of your compressor and dryer. Should it be as far away from the compressor as your space allows so the air can be as cool and dry as possible? I appreciate the DIY aftercoolers and the brass monuments with drip legs but, that’s not what I’m doing  I have the 2 stage Kobalt 60 gallon compressor and the Harbor Freight refer air dryer. Thanks, y’all

I have the 2 stage Kobalt 60 gallon compressor and the Harbor Freight refer air dryer. Thanks, y’all

There should be at least 20 feet of pipe between the compressor and compressed air cooler. The Harbor Freight Compressed air cooler wants the air coming into the dryer cooled to 175 degrees or lower. I have my air compressor on one side of the garage and the dryer on the opposite wall. I ended up with about 40 feet of 3/4 inch copper pipe between my compressor and compressed air dryer.

Thanks, Man. That’s the direction I was going with it. Concerning the line that is run across the expanse of my area… Was going with Copper mainly for the cooling effect? Price? Ease of use? I installed the RapidAir 3/4" line. Could I use that same PEX line to cover my run from the dryer to the Compressor? Currently it was just going from the Compressor through the whip and into a 3 stage dryer. The beads in the desiccant filter are pink within an hour. It is a really short run to the Plasma table.

I also use rapid air line between the compressor and dryer/filtration. Compared to copper it’s not going to have nearly as much heat exchange with the surrounding environment, but anecdotally my 50-ft run is dry. I don’t run through drying consumables nearly at the rate you mentioned here.

Is your setup similar in that you have them on storage sides of your space?

Pretty much. I have a Kobalt single stage compressor at one end of the building, and the room with the plasma cutter is near the opposite side. The run I have is straight line distance and just happens to be around that length. If you are running production or cutting thicker plates, you may have different results. I generally do quarter inch and under aluminum and mild steel so jobs are pretty quick to complete. I only have 40 gallons of storage, btw.

I am running similar thicknesses and type of material. I have pretty much obligated myself to this set-up at this point. Not that it is a bad choice, I just am at the nickel and dime stage and have made my choices based on what I think is due diligence . Or at least I hope so

I have found that even with a cooler its good to use a water trap after it. My thinking is its much easier to pull water out of cooler air. I ran my compressor the other day with humidity hovering around 100% for about an hour nonstop and first water trap after my cooler had about 1 cup of water but with my setup my secondary water trap before the desiccant was completely dry.

Man i just set mine up and i can follow up with pictures, but long story short i did not imagine that it would make that much of a difference but being close to the gulf of Mexico its hot and humid here like hell. i seen a major dif in cut. i did buy a coiled 20’ hose from amazon so far so good. one thing i did add after the cooler is an additional passive dryer with siica.

mounting these verticaly next to the 60 gallon compressor, they are out of a BART train 21 gallons each

air goes in the top of one and down to the next tank, then out the top. should help with water

Does this mean there’s a BART train somewhere running without braking capability?

For those of you running the Harbor Freight Air Dryer are you installimg an oiler to the inlet like the instructions say.

I am not. You would need to remove the oil before it got to the plasma cutter.

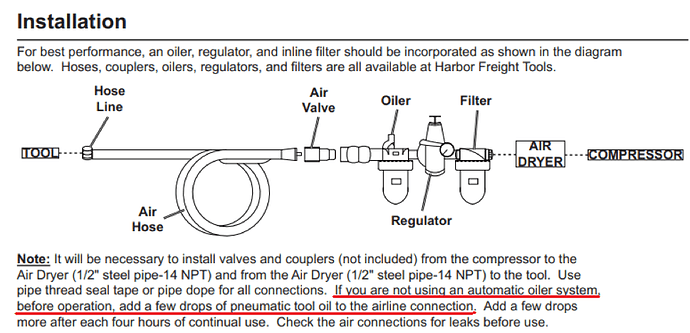

Notice, that only pertains to compressed air tools. In the diagram it is after the air dryer so it has nothing to do with the actual dryer:

The instructions say to add the oiler AFTER the dryer, not before. And, as @ChelanJim points out, that’s only for tools that require oilers. Plasma Cutters (or Paint Sprayers for that matter) do NOT fall into that category.

I totaly missed that was just reading the undelerline . Thank you. Should have paid close attention the picture

I have the HF dryer inline that I purchased years ago. I really only use it for my powder coating setup. Maybe something has changed over time but the one I have is max 90 PSI input. Any higher and it one of the internal hoses comes loose.