The price of the harbor freight air dryer just dropped to $299. I think I may do it.

Does the price drop get anyone else interested?

Owners manual

The price of the harbor freight air dryer just dropped to $299. I think I may do it.

Does the price drop get anyone else interested?

Owners manual

Whoa…that’s insane! I’ve been looking at drying solutions and bought the motor gard filter - this is only a short step up $ wise. My problem is I don’t have 50’ to cool off - so one of these is very interesting. Thanks for the heads up…I saw a video of a guy that had some issues with the HF cooler - but I could probably fix it if it went wonky on me…

Why? This thing does the same thing, always runs without electricity, never needs repair.

I really don’t understand why you would bother with an electric air dryer.

Space mainly. I’ve decided to stick with my motorgards and see how they do. I’m also replacing an AC on Monday and am going to have them leave the old units behind. I may see if I can cut it up and make something like the copper runs, but in a smaller package.

But the price on that unit is not bad.

I installed that copper unit after I figured out that the motor guard does not work very well with hot air.

It just does not pull the fine moisture out enough.

Thanks for that info on motorgards - I’ve been a little worried my run from compressor is too short. My motorgard is 4 line ft from the tank and doesn’t have much time to cool. they say to have 50’. That’s why these air dryers are interesting to me. I like simplicity of the copper lines, though. I need a bigger shop.

My garage isn’t cutting it.

Do you still run the motorgards after your copper loops?

I installed one right at the back of my plasma and I’ve noticed a huge difference.

@brownfox Thanks for the heads up!

Well, YEAH! We all do!!!

You installed the dryer or a motor guard?

I was going to put my motor guard 3 feet away from my tank. I have the aftercooler too though, so it may be ok since the tank isn’t getting 300 degree air.

The thing im thinking about the air dryer right now is that it says to run it right off the tank, but that it’s optimal working pressure is 100 psi. Are they saying I should regulate the pressure down to 100? If that’s the case it would have to be down from the regulator of course.

Wouldn’t having the dryer be better than the copper tubing run on a day where ambient temp is really high? The dryer says it lowers the dew point to 36 degrees. I’m wanting to research this more, since there’s a few things I want to understand.

For example, if I’m using air so fast that it’s coming from the pump at 300 degrees and only cooling say 10 degrees before it hits the plasma, that’s bad right? Because the moisture is still in the air, it’s just hot and not condensing?

So if my shop is 80 degrees and the pipes are at 65, , that’s as cool as the air will get running through the pipes, leaving some moisture still in the air? If the dryer gets it to 36, isn’t that the best scenario?

Yes, I feel like this rambles. I need to do more research when I get time, lol.

Motorguard

I still have the motorgaurd behind the copper runs. It is always bone dry but I want it to filter any potential oil or other crap that may sneek through.

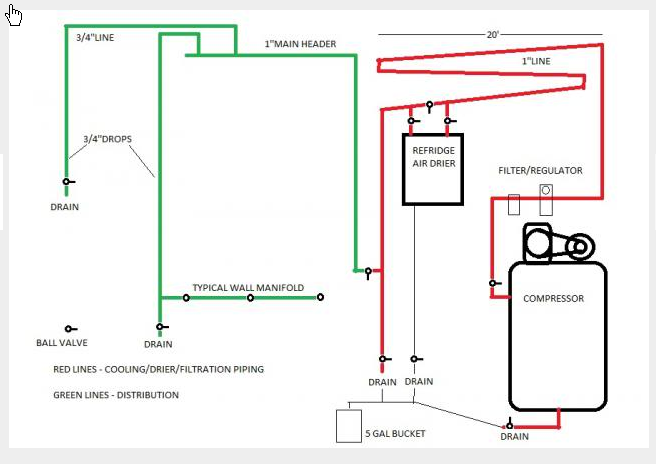

It is recommended that the compressor air dryer be 20 feet downstream so the air has time to cool off so it will let the compressed air dryer work more efficiently.

This is How I have dried air from 1/16 hp units to 10k hp units (oil free - oil flooded) all over the country.

The key is to get the moisture, water vapor, and oil vapor suspended in the air out of the system.

Depending on where you live and the humidity conditions in can change drastically from season to season.

Each of these steps will take it to another level (at more cost) it really depends on the criticality and application of how dry the air needs to be.

You can haul a 1000lb crate of potatoes with a mini pickup truck or a Semi Truck or something in between

I just got back from Harbor Freight. I had bought the air dryer on-line at the old price in March 2020. Since they can only refund the difference if the price change happened within 30 days, and it had been about 35, I had to technically do a return at the old price and re-buy at the discounted price. I also bought a 1 year extended warranty since if it is going to break it is more likely going to so in the first year rather than the second.

Did you ask for an additional discount when you bought back your unit? Lol. Technically it’s used.

Actually it is “used” but never hooked up. I just removed the box temporarily since many complained about shipping damage. Mine had none.

The info on the HF site says Max input 150psi, so with my 175psi Kobalt compressor, I need to regulate before the refrigerated dryer, correct? Hate to blow it up if I get one. Drop down to say 125 then regulate the output to about 75 for the RW45 I’m guessing.

Yes you need to regulate before the air dryer. I’ve read reports where people had issues of internal leaks due to supplying more than the max.