Have you introduce any"feed rate optimization" into your program?

Feed rate optimization is when you slow the torch down during some of the geometry to reduce bevel in slots and holes.

This video discusses it briefly during this overview of the fusion 360. Sheet also has its methods of achieving this.

Slow down your feed rate (IPM) to 50-60% of the cutting speed just before and during a tighter radii can reduce bevel. It allows the normally trailing plasma stream to “catch up” with the cut. This may help your bevel issues for the tight radii.

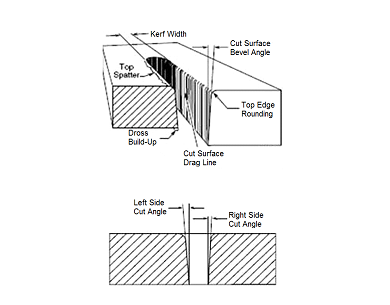

Some bevel is expected with plasma cutting.