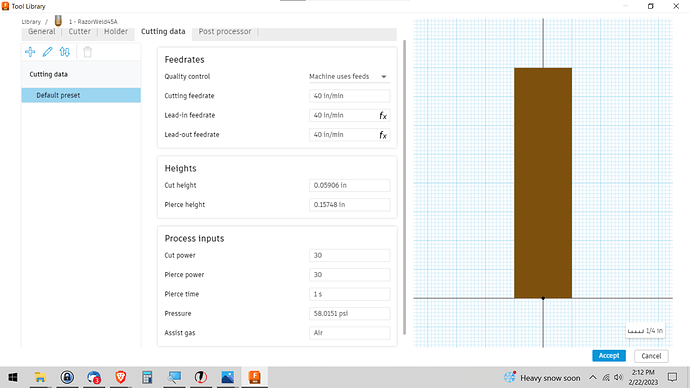

I’m new to cnc plasma however I do have experience with using hand held plasma. I have Cross Fire Pro with RazorWeld Cut 45 and machine torch. Also using Fusion 360 for my cad/cam. I’m still learning and trying to refine my process. So far I have cut about a dozen parts/designs using various thickness mild steel. Still trying to dial things in. I’ve been feeding the RW plasm 75 psi dry air. My understanding is the RW will internally regulate the air pressure accordingly. I’ve only been adjusting the amperage/power setting according to my metal thickness. So far everything seems to be working as expected. All that being said I was looking a little closer in Fusion 360 at the Tool Library setup. I noticed under the cutter data tab is a process inputs section. It has “cut power” setting and air “pressure” setting. Am I supposed to be making these changes there and running the plasma maxed out rather than manually adjusting power at the plasma and letting the plasma internal regulator do the air? I’m confused. Can anyone give me a hand sorting this out? I took a screen shot of the area in F360 I’m referring to. I’m not certain how to attach the photo to this. If someone can tell me I will add it. Thanks in advance for help.

Rich~

I looked in other threads on this forum for answers to my question but struck out. If this has already been covered someone please direct me to that thread. Thanks.

Ok I will answer a couple questions.

Air pressure is controlled by a regulator inside the RW, if you want to change it you will need to take the cover off.

Most people turn the regulator on the inside all the way up and add another regulator upstream of the plasma cutter or to the rear of it. I guess you just move the one from the inside to to the outside so you can get it.

At some point you will need to adjust air and having it inside is useless.

Amps are set on the machine.

The amps and air settings in fusion are there so you know, when looking back what you choose for that set up.

You can store different tools (plasma cutters) in fusion with different settings so you don’t have to enter them manually every time.

I understand now. Thanks you.

Hey Knick, I was looking through topics concerning Fusion360 (as I have zero experience with it). Your comment actually sparked a couple of questions I am hoping you can answer.

Do you know if the free version of Fusion360 allows you to store the settings for the Razorweld45 (or any plasma cutter for that matter.)

The other question concerns air quantity requirements. I’m working on getting the machine set up and looking at air compressors (ad nauseam), I’ve come to the conclusion that throwing $1000 at a compressor purchase buys basically the same pig with different lipstick. I’m wondering if a 110v compressor that can provide 175 PSI max working pressure, 6.2 SCFM at 90 PSI and costs $600 might be the best approach starting out. (Though I hate buying something twice.) My question is would a DeWALT 2 HP 30 gal. Single Stage 175 PSI Air Compressor with the aforementioned specs mentioned be enough to keep up with the plasma cutter? I am planning on purchasing the Hypertherm filter/dryer and a regulator (that I am open to recommendations on).

The other question concerns length of line between the compressor and my Crossfire Pro. Is there any rule of thumb concerning distance? Do longer distances create more moisture to have to deal with?

Thanks in advance for any advice you can provide.

I think you can do it in the free version. Brand of plasma cutter does not matter.

That compressor would be the bare minimum.

I would never set the air pressure above 130psi

There are lot and lots of post on air drying if you do some searching on the forum.

As far as air lines the further the compressor is from the table the larger it needs to be. If you keep the compressor within maybe 20 feet you should be ok with 3/8” air hose. And use high flow couplers they will help.

All of this can get pretty involved but there is a ton of info on the forum just takes some searching.

Yeah, I know the compressor is pushing the envelope. I’m still scratching my head about which way to go in that department.

Thanks for your tips. I’ll check to see if the couplers I have are high flow.

I’ll root around the forum some more.

Thank you!

the smaller the compressor the more likely you will have higher compressor temps. the higher the temps the harder battling moisture will be.

One thing to think about when sizing your compressor is, will you ever need more air? if so you will need a bigger compressor. Did you look for a used one?

I see used ones all the time up for sale, just make sure its not real old as the tanks get rusty and can get weak.

Quality plays a big role in what you get, I know of a old Quincy that is over 60 years old still has the original tank.

But everything 60 years ago was made to last a long long time!

Yeah, this is the conundrum. I want a bigger compressor but they seem to jump from $1k to $1500. Reading the customer reviews on the delays for warranty service is off putting. I am trying to find that sweet spot. I want a bigger compressor (and less moisture) and DEFINITELY enough to deliver clean cuts. Is there some CFM number @ 90psi that can be used to “back into” a compressor make/model of sufficient size with a little bit of headroom for margin?

I have been looking but my FB profile doesn’t have any buy/sell history and I guess a lot of folks don’t reply to those. At least that’s been my experience. I ditched my old FB page years ago and have only gotten on recently.

I saw a sweet looking Saylor Beall yesterday for $500. It was older but was a nice looking machine. Got snapped up quick.

I am definitely open to those older ones than I am even a new one. Machines REALLY made in America seem much more dependable than all of the same machines on todays market that are just painted different and have different decals… Like you said though, integrity of the tank, etc. definitely is something at least I wouldn’t know how to determine. Are you saying that that Quincy is for sale?

***One thing I will mention just in case anyone else reads this… I hope I am not breaking any rules here but it pays to do your research. I understand this isn’t the ideal unit but I just wanted to share what I came across in terms of price… LOOK AT THE PRICE DIFFERENCE BETWEEN Tractor Supply Price and Lowes Home Improvement for the exact same model. I couldn’t believe it! BUYER BEWARE!

No not for sale just was using it as an example.

If your looking for a used one I would watch for any local auction’s, market place, Craig’s list and eBay

Make sure you make sure what ever you find is is single phase and not 3 phase.

It will all depend on fast you need to find one

My advice for you is to look at the plasma cutter you plan to use see what the requirements are. Doing CNC cutting I would double that. Make that your target. Even if it has a semi small tank. I also recommend doing a good drying system that is required. After all that look around you can find free air compressors that have a good tank but bad compressor. Plumb that in after the air drying equipment that will help with pressure drop. Last put some sort of filter right before the plasma you will eventually get a rusty dust out of the dry tanks.

Yeah, I’m definitely looking for single phase.

I have two things I am facing; I am short on time to get this situated. I do woodworking and just have gotten my new CNC for that side going well. i’ve been wanting a Langmuir for a long time and couldn’t pass up the chance. I have some orders already if I can get it all of the wiring and air compressor situated. It’s tough doing everything solo. I live in a remote area and no one really around to give me a hand. The other thing is delivery of a machine isn’t possible. My driveway is almost a mile long and t’s an adventure to get up here. No delivery truck could make it up here.

Well now you have just added more pieces to the puzzle.

Yeah, I might should have led with that stuff . FWIW, working solo, I’ve learned to make good use of dollies, straps/chains and my shop crane though. …Physics is a beautiful lady as long as you don’t break any of her rules.

Yeah, I’ve got the Razorweld 45. I am getting the Hypertherm dryer/filter. Hopefully that will be enough. I saw someone on here using a whole house water filter filled with desiccant as a dryer as well. If it wouldn’t reduce airflow I might put one of these on as well. This is the unit I was considering.

How much cutting do you plan to do? I wouldn’t recommend the water filter at all. I know the pressure rating may be ok. The filters a designed to work different.

Also if you plan on using it a lot the bead dryers don’t like hot air. So a aftercooler post tank will be your friend.

Well, I’d love to be cutting so much that I would even need more machines but I don’t think I have enough time left on this mortal coil to worry about that happening. Seriously, I would like to be cutting on a regular basis. Maybe create some niche markets and also depending on how detailed and small I can cut, I could see the machine running at least a few hours a day.

I actually have a 26 gallon Kobalt that died after 18 months (I lost my receipt and I’ve spent hours on the phone with Lowe’s and somehow my receipt on their records must have burned up in the ether.) I will gladly incorporate that into the mix if I can figure out how to plumb it. I assume I need to pull the head off, etc., correct? Not sure if 26 gallons would be stellar but at least it wouldn’t work the compressor like a rented mule.

Two positives about going with the smaller one I included in my last message to you is that I don’t have to worry too much about the wiring (though I don’t see the amperage requirement in the specs.) Also, I can have a place that it can fit in my shop that will be very close to the plasma cutter.

In your opinion is the Hypertherm filter/dryer sufficient? Any recommendation on a decent regulator?

Knick mentioned doing 3/8" high flow but I just noticed this has 1/4" high flow regulator. Not sure of the implications of that.

I don’t want to come off as a complete ninny. I am a pretty good shade tree mechanic. Just completed a total tear down restoration on an old Farmall 140. Also, I do pretty fine woodworking. Not boastin’. That is just from doing it for 50 years. (I actually just did the math to write that last sentence. Man that’s depressing.) I just mention this because I can handle doing the work. When it comes to air and electricity, I just don’t know all of the dynamics to consider and what I need to do to address them.

Worth mentioning, ultimately, I plan on getting a bigger compressor and I may even find a used one in the next day or so but if I don’t I just want to be buying $600 worth of aggravation and subpar cuts from the plasma cutter if I bought the particular one that’s in stock that I linked to you.