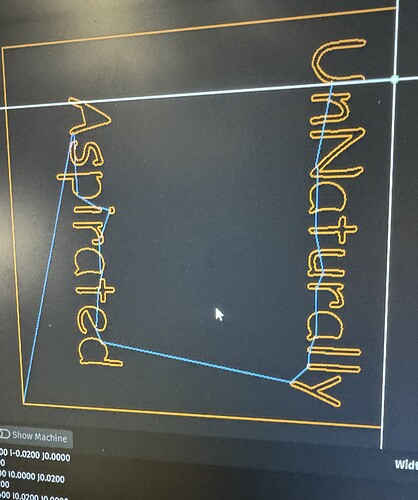

This is so weird , if I flip it 90 it will cut top and bottom but the letters are flipped

Can you show some photos/videos of the metal?

Did you use your file or mine?

Your file … I’ve been doing a dry run . The video will be too big to upload here . I line up on the corner , it will rapid and start cutting the bottom . Then rapid underneath and start cutting what’s on top . Maybe I can make a YouTube video

Are you looking at your table upside down? Can you post a video?

There is a possibility that your visualizer is not keeping up. Are you watching the torch and see that it is skipping all those letters or are you just watching the visualizer.

If it is the visualizer giving you this information, perhaps that needs a re-install. There has been lots of folks having their visualizers shut down and most of the them get up and running again with re-installs but others are needing to resort to the stable/older version of FireControl.

I’m almost certain you’re just oriented to the table wrong. Stand on the other side of it and run the program.

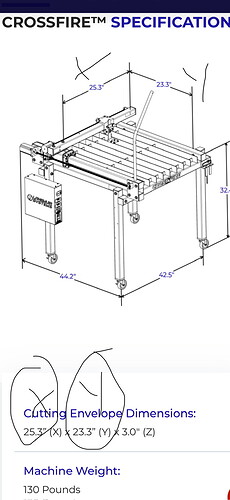

You are not looking at the table correctly, and you may have your motors plugged in wrong. You have your axis mixed up. On the crossfire, the X is what the torch is mounted to.

The “front” of your table is with the torch mounting bracket facing you. That is how firecontrol displays. So “home” if you have limit switches is the top left.

I was thinking that it might be that . So x is the gantry and Y is the other

I’m going to give you a hard time in a light hearted fashion, because you are clearly learning, you answer questions and post video and have a good attitude. All things that I like. But…

You’re killing me smalls. I gave you the picture. Although the picture looks like I drunkenly drew on my phone with my nose.

When did you start thinking you were looking at it wrong? The first, second, or third time I said it! Bah! I’m pulling my hair out over here. I want to see you cut that thing!

Go check what plug you put each motor to on the front box, turn the table 90 degrees clockwise from where you showed it in the video and everything will work.

I’ve made several mistakes setting this thing up …. Been rushing to get it working , I have two cnc milling machines I retrofitted, you’d think I’d be able to assemble this shit ![]()

![]() . Deserve every bit of criticism … such stupid mistakes. It’s working as expected now. Do you happen to know … the limit switches , do they only work during a real program … They don’t function during dry runs

. Deserve every bit of criticism … such stupid mistakes. It’s working as expected now. Do you happen to know … the limit switches , do they only work during a real program … They don’t function during dry runs

It’s all good man, it happens. I wouldn’t catch these things if we hadn’t seen it before. I made weird mistakes too. It’s all part of the process.

Limit switches should be functioning all the time. They function while jogging. Do you have them enabled in settings and have you set your soft limits?

sasani,

If you can admit your mistakes and make fun of yourself… you’ll fit right in around here.

Welcome to the dumb mistake club. We’ve all been there and got the tshirt. Ask me how many times I’ve started a cut with the earth clamp laying on the floor next to the machine. (you can ask … but I’m going to lie!!!) ![]()

Bruce

Not only a great trait to admit mistakes but you also illustrated the fact that the more information you supply, the more that people can get their thoughts around what is going on.

It has been a pleasure. Kudos to BrownFox and to @Sasanifab

I haven’t activated anything in the settings , the light goes on when the switch is closed ….ill take a look at the settings. Trying to wrap my head around these limit switch’s , the stepper motors aren’t really that strong so I’m having a hard time understanding the point of them … My milling machine servos are so strong they would rip the yoke mount off the saddle ….

The limit switches, by default are closed. When pressed they are open. That means that if a wire is not connected, it would show the same result as if the switch was pressed.

The benefit of the limit switches is they can prevent you from loading a program that’s too big (once you set soft limits) and they are the only way to guarantee an absolute zero reference in the event you lose steps in a cut or lose your work zero.