Look at the speed that my machine is cutting at and you can see it is not moving at 100 in per minute

to make sure i am understanding, you set it at 100ipm in 360, but arnt getting it on the machine?

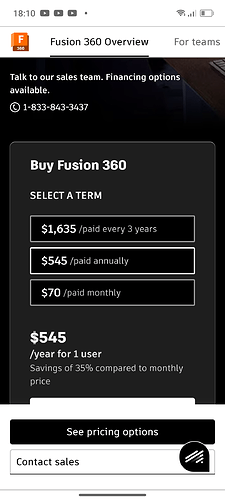

Yes this is what I am saying we set the thing to do 100 in per minute and we didn’t see anywhere near it the program was meant to take 2 hours and 14 minutes instead it took 4 hours and 34 minutes due to the feeds and speeds being a lot slower the only thing we could do is go ahead and purchase a license from fusion 360 Autodesk showing that we can have control on our machine it was explained to me that with a free copy you do not get all of the feed speeds and parts that could be available to you with a license copy so I will just have to pay the $70 a month and live with it

What does the machine show for feed rate while its in motion?

This is my number one gripe with F360 as the free version. Any rapid moves are replaced with the slowest feed rate on your cycle.

I’ve been manually editing the programs and changing retract moves to higher feed rates or rapid moves. I’ve taken a 45 minute program from F360 and dropped it to 20 minutes by correcting those feeds. Only do this if you’re somewhat fluent in cnc programming and G code. A fast feed or rapid in the wrong place will cause bigger problems than a slow program.

I use a program called NC Corrector that shows the movement of the program, very similar to what the CC interface shows, but with the ability to edit the program and see your changes in real time. Can be a good tool for visually verifying your program before running it as well. It gives an estimated cut time that is pretty darn close also.

Okay while the mr1 is running it will show the correct speeds and feed but I know the sound of the spindle when it’s spinning at 8,000 RPM the spindle is running around $5,000 RPM and the step over is a lot less than what we programmed so with this this increases your cut time and everything else that goes with it. If I have to purchase a license to run my machine at full speed and it cost $70 a month then what choice do I have I like to make parts for me and my boys our toys require a lot of machine work which we cannot afford to keep sending out this is why we purchase mr1

I’m curious about what you’re saying. The readout shows 8000 rpm and a feed rate of 100 ipm?

Realistically the machine is only going to read the G code provided by the program. And there is no code to make the machine run slower than what’s being displayed. If the machine is actually running slower than the display then it’s a machine problem, but the only way to know for sure is to put a tach on the spindle to check rpm. To measure feed time over a given length would give you a pretty close estimate on the actual feed rate.

Keep in mind too that if the program is moving in an arc or at an angle the individual X and Y axis wont both be moving at 100ipm. They will be reduced some amount to equal 100 ipm in the direction of travel. That and the feed smoothing from move to move also reduces it further as the tool changes direction.

I’d be curious for you to check actual rpm and record distance and time of travels to see what the machine is running at.

This isnt a MR1 issue, you would see the same thing on other CNCs too. This is what you get with the free version of 360, thats it. either pony up for a license, or edit the code to increase speeds.

I don’t think fusion is limiting your spindle rpm or your step overs just rapid feed rates. If cutcontrol is reading 100 rpm its spinning 100 rpm or something is wrong with your spindle.

You have the option to just cut parts slower… its not the end of the world unless you are in production and if you are then you could easily pay the license.

No I do not have a problem with paying for the license and I make small parts for my play toys the drag bike and the race car is what I make parts for I do not sell anything I just like to have the edge over whoever I am racing. Fusion does a bit more than just your rapids the machine gets slow as hell and I went to the spindle override it said 8,000 RPM and I can still make it spin faster when I hit the override now it’s still displays 8,000 RPM even though the spindle speed is going up but the display still says 8000 there is nothing wrong with the machine it’s just I will have to pay for the license if I need to cut quicker it will probably be cheaper to buy the license then to work with other machine shops that take 3 to 5 weeks to do a simple job

This is why I bought the mr1 to play with this particular vehicle and a few others that we have I have zero problems with pain for the license but at the same time I didn’t think it would take that much control on my unit I will go out and get it $70 a month for a year or so unless something else comes up

You could also buy a year at one time and then it would only be about 46 $ a month.

And they’ve been pretty consistent about offering 30% off 3 years a couple times a year.

Fusion 360 | 3D CAD, CAM, CAE, & PCB Cloud-Based Software Autodesk Fusion | 3D CAD, CAM, CAE, & PCB Cloud-Based Software | Autodesk

Which works out to about a dollar a day.

Well today was a good day I got to talk to order this customer service and I was given some good news as to how to beat this problem temporarily. They told me to get the startup package and I can renew it for free years for free it comes with all the features I need to do what I’m doing they call it the entrepreneur package I signed up for it and it takes 10 to 14 days before they get back to you meanwhile I will keep playing with mr1. So there is lights at the end of the tunnel I just thought you all should know that there is a way if you talk to auto desk direct